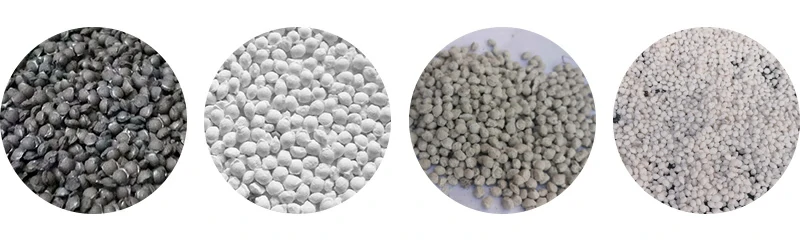

The double roller granulator is a dry granulator. The raw materials enter from the feed hopper and are extruded through the mold shells above the two roller skins. After demoulding,they enter the crushing and molding module at the lower part of the roller body to crush the entire particle board into Loose particles coming out of the machine. The particles are in the shape of flat spheres, and the size of the particles is deter-mined by the size of the mold, which can be customized.

A double roller granulator is an equipment that uses dry granulation technology to make powder or loose materials into particles. Its working process mainly includes two stages: extrusion and granulation, which are closely connected and work together to complete the conversion from powder to particles. Here is a specific introduction:

Overall, the double roller granulator is an efficient, energy-saving, and environmentally friendly granulator, especially suitable for applications where hard particles can be formed by the intermolecular forces of the material itself without the need for adding adhesives. Its concise working process and numerous technological advantages make it have important application value in multiple industrial fields.For more information, please contact us by sending an inquiry today! We can help you!

World-class and Energy-saving Operation, Factory Price & Fast Delivery.