【Application】Production of various concentrations and types of compound fertilizers (including organic fertilizers, inorganic fertilizers, etc.)

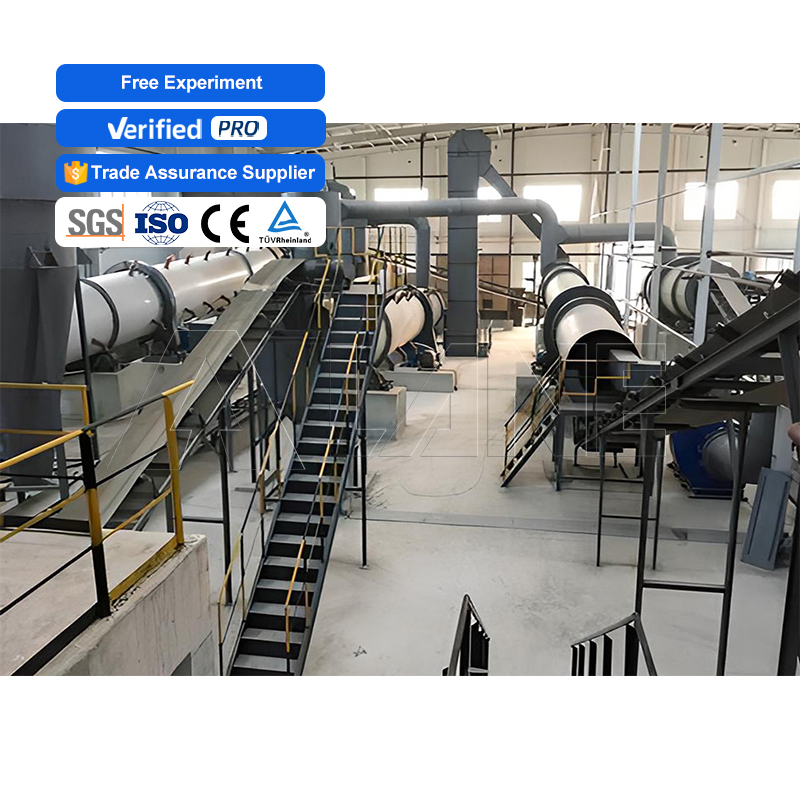

【Equipment 】Crushers, conveyors, granulators, elevators, finished product sieves, etc.

The organic-inorganic compound fertilizer production line adopts a two in one granulator, which is suitable for cold and hot granulation as well as large-scale production of high, medium, and low concentration compound fertilizers. The main working method is wet granulation of pellets. The production line of organic-inorganic compound fertilizer can be equipped with a complete central control system to achieve fully intelligent operation. Five year warranty for important components, providing you with worry free after-sales service. A team of professional engineers to assist you in resolving installation issues. Voltage, color, logo, etc. all support customization, and we can meet all your customization needs.

For more information, please contact us by sending an inquiry today! We can help you!

Raw material ingredients: urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, heavy calcium, superphosphate), potassium chloride (potassium sulfate) and other raw materials are prepared in a certain proportion .

Raw material mixing: Mix the prepared raw materials evenly to improve the overall uniform fertilizer efficiency of the fertilizer particles.

Raw material granulation: The evenly mixed raw materials are fed into a granulator for granulation .

Particle drying: The particles made by the granulator are fed into the dryer to dry the moisture inside the particles, increasing their strength and facilitating storage.

Particle cooling: The dried fertilizer particles have a high temperature and are prone to clumping. After cooling, they are easy to pack, store, and transport.

Particle classification: The cooled particles are classified, and the unqualified particles are crushed and re granulated to screen out the qualified products.

Finished film: Coating qualified products to increase the brightness and roundness of particles.

Finished product packaging: Bag the coated particles, which are the finished products, and store them in a ventilated place.