A horizontal mixer is a device that uses a horizontal mixing shaft to mix materials, especially suitable for mixing dry, semi dry, viscous and other materials. It can mix materials evenly with minimal residue, making it very suitable for mixing animal feed, concentrated feed, and fertilizer.

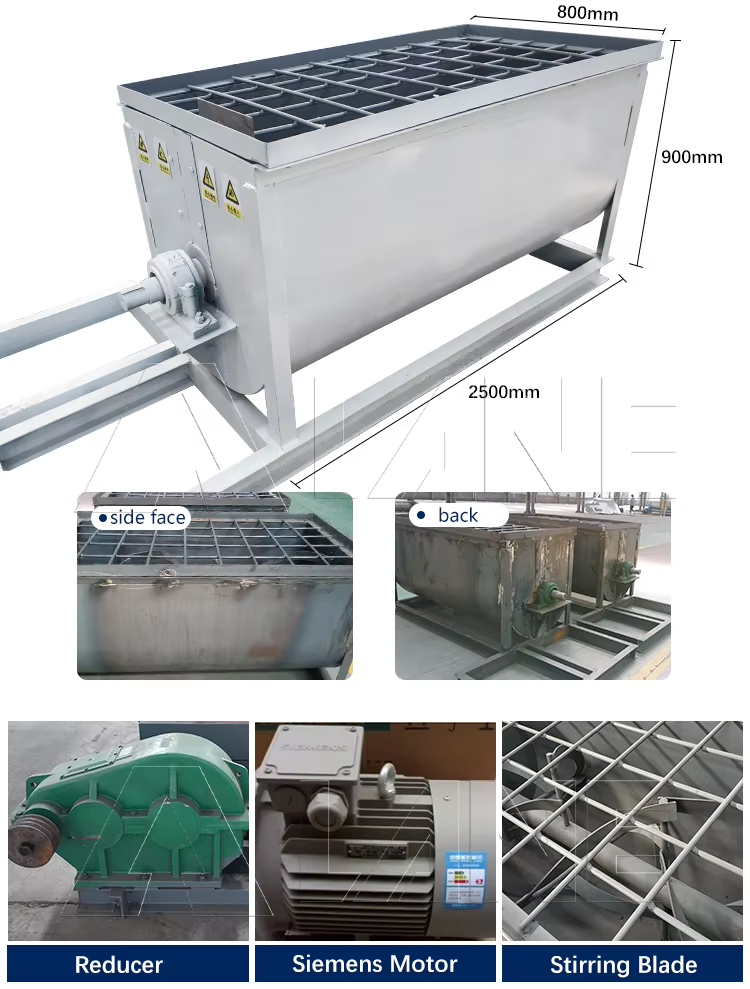

A horizontal mixer is an advanced and efficient mixing equipment that utilizes the interaction between the inner and outer screw belts to flip and circulate the materials inside the drum, thereby achieving a fast and uniform mixing effect. The horizontal mixer is mainly composed of a U-shaped mixing drum, double-layer or three-layer spiral belt mixing blades, and a transmission device. These components work together to enable the mixer to process various types of materials, including powders, particles, and liquids.

The design of the inner and outer screw belts ensures that the material undergoes three-dimensional convective motion inside the cylinder. The outer screw belt pushes the material from both sides of the cylinder towards the center, while the inner screw belt transports the material from the center to both sides, forming a continuous material circulation and mixing process.

The transmission system of a horizontal mixer usually uses a belt pulley to drive a cycloidal reducer. This transmission method has the advantage of protecting the transmission components when overloaded, improving the safety and reliability of the equipment. The discharge port at the bottom of the mixing drum is designed as a pneumatic large door structure or a manual/pneumatic butterfly valve to adapt to materials with different physical characteristics, ensuring a fast and residue free discharge process.

In specific applications, horizontal mixers can also be equipped with jackets for heating or cooling, providing more possibilities for specific process requirements. The heating method can be electric heating or thermal oil heating, while cooling can be achieved by directly injecting cooling water. This flexibility makes the horizontal mixer not only suitable for conventional material mixing, but also able to meet the operational requirements under special process conditions.

The efficient mixing ability, strong adaptability, and easy maintenance of horizontal mixers have made them widely used in various industries such as chemical, food, and pharmaceutical. Through a deep understanding of its working principle and structural characteristics, users can use and maintain the equipment more effectively, thereby extending its lifespan and improving production efficiency. Whether it is batch mixing in the production process or small batch testing in the research and development process, horizontal mixers can provide consistent and uniform mixing effects, ensuring the quality and performance of the final product.

For more information, please contact us by sending an inquiry today! We can help you!

World-class and Energy-saving Operation, Factory Price & Fast Delivery.