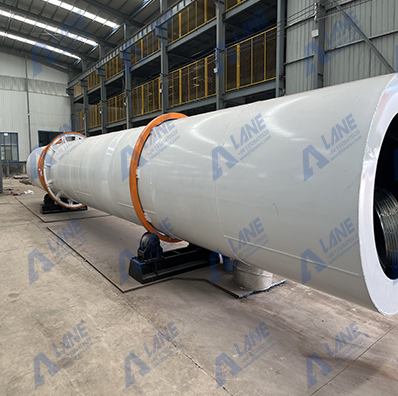

The rotary drum cooler/dryer is a commonly used cooling equipment on the fertilizer production line, mainly used to cool and dry fertilizer products. The dried hot fertilizer is fed into the drum through the feeding device, and the cold air system introduces outdoor air into the drum to form convection, taking away the heat in the hot fertilizer and achieving the cooling effect. Rotary drum cooler have been widely used in the field of material cooling due to their characteristics of uniform cooling, high efficiency, energy saving, and easy operation.

The rotary drum cooler/dryer uses newly obtained heat energy (such as cold water or cold air) to directly contact high-temperature materials, and applies the principles of heat conduction and convection to remove heat from the materials. The core component is a drum designed with a guide plate, which optimizes the heat exchange effect and promotes the flipping of materials inside the drum, resulting in more uniform cooling.

The rotary drum cooler is also equipped with an automated control system, which accurately adjusts operating parameters, monitors equipment status in real time, and ensures the stability and safety of the cooling process. Widely used in industries such as chemical, building materials, and food, rotary drum cooler are characterized by their high efficiency, energy saving, easy operation, and convenient maintenance.

For more information, please contact us by sending an inquiry today! We can help you!

World-class and Energy-saving Operation, Factory Price & Fast Delivery.