【Applicable material】Sugar dregs,Wine dregs, soy sauce dregs, vinegar dregs, furfural dregs, xylose dregs, enzyme dregs, medicine dregs.

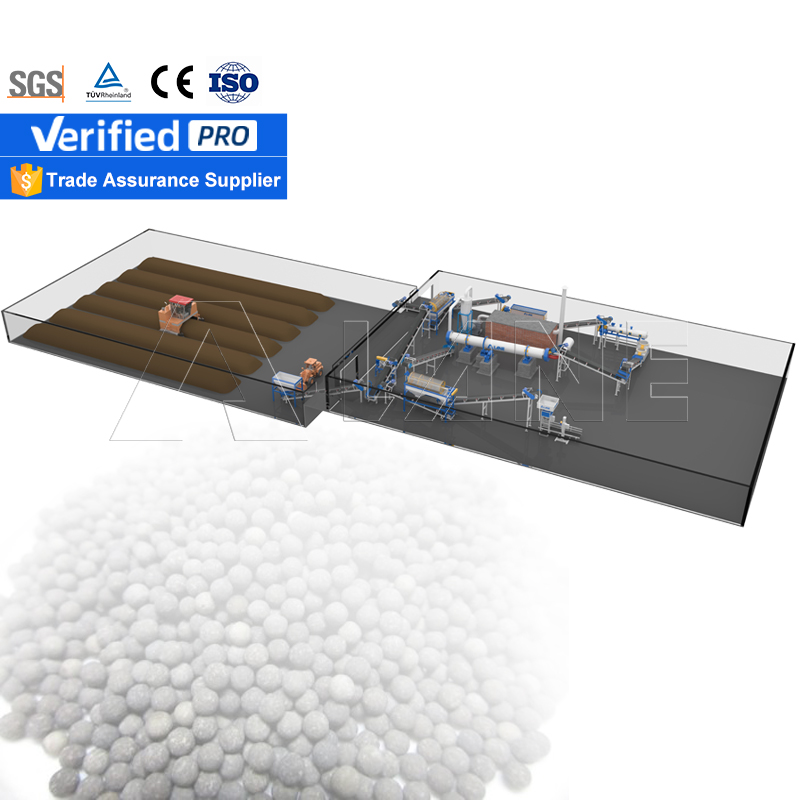

【Equipment 】crusher, mixer, granulator, dryer, cooler, etc

The medicine dregs organic fertilizer production line is a comprehensive treatment process that converts solid waste such as traditional Chinese medicine residue and western medicine residue into efficient organic fertilizer. This production line not only solves the environmental pollution problem that drug waste may cause, but also transforms these wastes into organic fertilizers beneficial to agricultural production through resource utilization, achieving the recycling of waste.

The medicine dregs organic fertilizer production line is not only an effective way for pharmaceutical companies to solve waste disposal problems, but also an important cornerstone for achieving sustainable agricultural development. Through technological innovation and rational planning, the environmental and economic benefits of the medicine dregs organic fertilizer production line can be maximized, contributing to the development of green agriculture.

For more information about the production line, please contact us by sending an inquiry today! We can help you!

The production process of the medicine dregs organic fertilizer production line is very rigorous, involving multiple links and equipment. This not only ensures the effective conversion of medicinal residues, but also improves the quality and market competitiveness of organic fertilizers.

Classification of medicinal residues

Chinese herbal medicine residue: usually contains high organic matter and relatively low nutritional content.

Western medicine residue: Low organic matter content, but high organic nitrogen, phosphorus, and potassium content.

Crushing and mixing

Crushing: Use a grinder to grind the medicine residue to the appropriate particle size, usually 3-5mm.

Mixing: Mix with auxiliary materials such as straw, sawdust, etc., adjust the C/N ratio, and form materials suitable for fermentation.

fermentation process

Fermentation method: Aerobic fermentation is adopted, using high-temperature microbial agents for fermentation, which has the characteristics of fast heating, good deodorization effect, and thorough decomposition.

Key parameters: The optimal moisture content is 50%, the carbon to nitrogen ratio is 35:1, the flipping frequency is once every 10 days, and the inoculation amount of the composite microbial agent is 1.5%.

Fermentation cycle: The entire fermentation process lasts about 35 days, with a cellulose degradation rate of 76.97% and a lignin degradation rate of 33.59%.

Refine mixing

Refinement: The fermented residue needs to be further refined to ensure the homogeneity of the material.

Mixing: Use a mixer to mix evenly and ensure consistent fertilizer quality.

Granulation drying

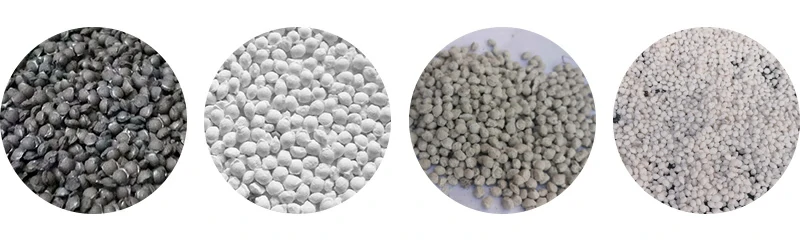

Granulation: The refined and stirred material is made into granular organic fertilizer through a granulator.

Drying: Use a dryer to dry the particles to the appropriate moisture level, improving storage and transportation efficiency.

Cooling screening

Cooling: The cooling machine cools the dried hot fertilizer to room temperature.

Screening: Separate the unqualified particles through a screening machine to ensure product quality.

Packaging and storage

Packaging: Qualified organic fertilizer particles are packaged by a packaging machine for easy market sales.

Storage: The packaged fertilizer should be stored in a well ventilated and dry place to maintain its effectiveness.