Cyclone dust removal is a device that uses the centrifugal force of rotating airflow to separate dust particles from gas. With its simple structure, easy maintenance, and large processing air volume, it plays an important role in multiple industrial fields.

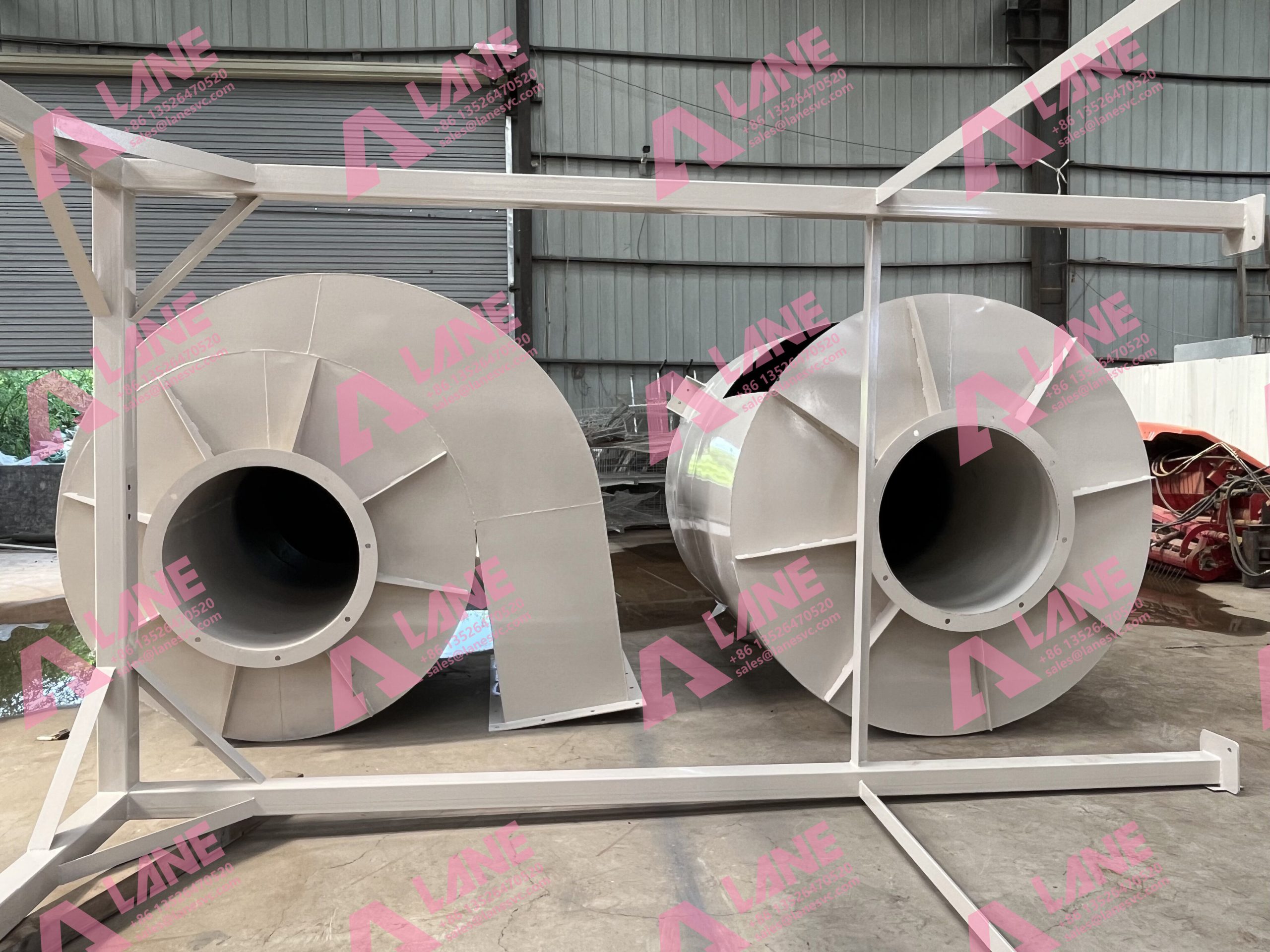

A cyclone dust removal is a device that uses the centrifugal force and gravity of a rotating airflow to separate dust particles from gas. Its main components include an inlet pipe, a cylinder, an exhaust pipe, a cone, and an ash hopper.

The working principle of this device is based on the concept of centrifugal force in physics, which effectively separates dust particles from gas streams and is widely used in industrial dust removal.

When the dusty gas enters the cyclone dust removal through the inlet pipe, its flow path is designed in a spiral shape, so that the gas forms a high-speed rotating airflow inside the cylinder. Due to the rotational motion of the airflow, the centrifugal force generated will throw dust particles with a density greater than that of the gas towards the wall.

Once dust particles come into contact with the wall, they lose their inertial force and slide down the wall with the help of downward gravity, ultimately falling into the ash hopper located at the bottom of the equipment.

As the rotating airflow continues to move downwards, the velocity of the airflow increases as it reaches the cone section due to the gradual reduction of space. This increase in velocity further enhances the centrifugal force and improves the dust removal efficiency.

When the rotating airflow reaches the bottom of the cone, it begins to change direction and swirl upwards to form what is called an internal vortex. During this process, the relatively clean gas gradually moves towards the center and is discharged outside the equipment through the exhaust pipe above, achieving effective separation of gas-solid phases.

The key to the design of a cyclone dust removal is its ability to handle a large amount of dusty gases while maintaining high dust removal efficiency. For larger dust particles above 5 microns, cyclone dust collectors are particularly effective.

However, for small dust particles smaller than 5 microns, their removal efficiency is relatively low, mainly due to the small centrifugal force on the particles, which makes them less likely to be thrown towards the wall of the filter.

The structure of cyclone dust removal is simple, easy to maintain, and there are no vulnerable parts, which makes it widely used in industrial fields such as mining, metallurgy, construction, chemical industry, etc.

Although the removal efficiency of fine dust is limited, by improving the design and adjusting the operating parameters, its ability to capture small particles can be improved to a certain extent, thereby expanding its application range.

For more information, please contact us by sending an inquiry today! We can help you!

World-class and Energy-saving Operation, Factory Price & Fast Delivery.