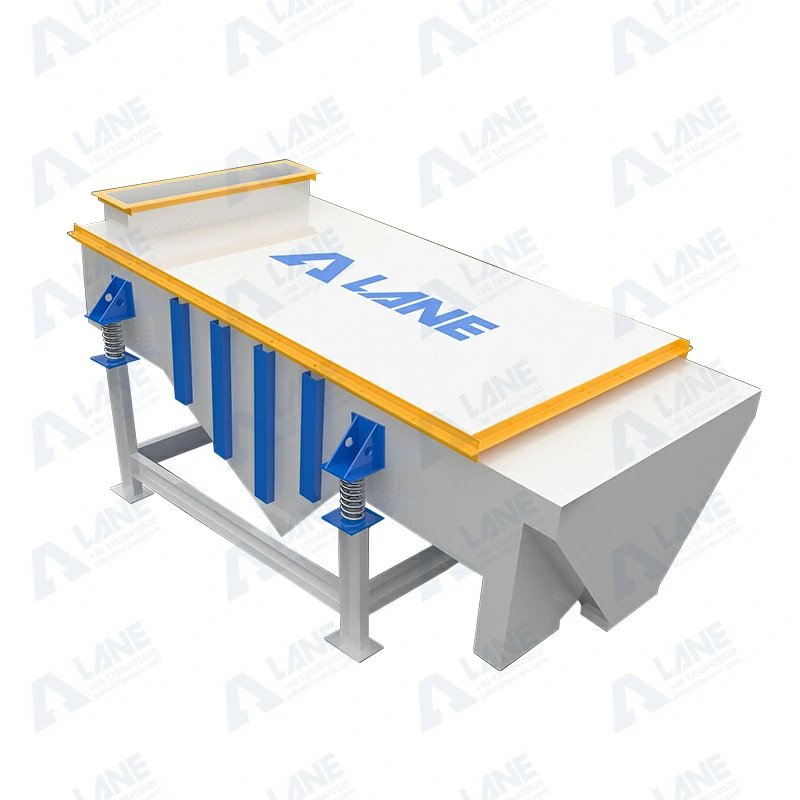

The vibrating screen machine is an efficient material screening equipment that generates vibration force through an exciter to make the material inside the screen box move in an “S” shape on the screen surface, thereby achieving efficient screening, filtering, and grading of granular materials.

A vibrating screen machine is a device that separates materials into multiple particles of different sizes through vibration force, thereby achieving screening, filtering, and grading. Here is a specific introduction:

working principle:

The motion trajectory of the vibrating screen is generated by the combined action of the upper and lower rotating weights of the oscillator. The upper rotating heavy hammer causes the screen surface to produce a planar rotational vibration, while the lower rotating heavy hammer causes the screen surface to produce a conical rotational vibration. The combined effect of these forces causes the screen surface to produce a complex rotational vibration. The projection of this complex spatial curve on the horizontal plane is circular, and on the vertical plane it is elliptical.

When the vibrating screen is working, the oscillator rotates under the drive of the electric motor, causing the screen frame to vibrate. Due to the vibration of the screen frame, the coarser solid particles remain on the screen surface when the material flows onto it, and are discharged from one end along the inclined surface. The finer solid particles and liquid flow together through the screen holes to the discharge port.

The screen box of the vibrating screen machine is equipped with multiple layers of screen mesh inside. After the material enters the screen box from the feeding port, it undergoes an “S” – shaped motion on the screen surface under the action of vibration force. In this process, smaller particles pass through the sieve holes, while larger particles are blocked on the sieve surface, thus achieving material screening.

The specific work process is as follows:

1. Material feeding: The material enters the sieve box through the feeding port and is evenly distributed along the sieve surface. The material is divided into multiple layers on the sieve surface, forming a certain thickness of material layer.

2. Screening: The vibration force of the vibrating screen machine causes the material to undergo peristaltic motion on the screen surface, resulting in friction and mutual impact between the materials, thereby allowing smaller particles to pass through the screen holes and larger particles to be blocked on the screen surface. In this way, the material is sieved into particles of different sizes.

3. Filtering and Grading: Particles of different sizes pass through the sieve holes and are collected at different discharge outlets according to the size of the sieve holes. At the same time, the screen surface of the vibrating screen machine also plays a role in filtering and cleaning, which can remove impurities and moisture from the material.

4. Cleaning and maintenance: Regularly clean and maintain the vibrating screen machine, keep the screen surface clean, clear blocked screen holes, replace worn screen mesh, to ensure the normal operation and service life of the equipment.

For more information, please contact us by sending an inquiry today! We can help you!

World-class and Energy-saving Operation, Factory Price & Fast Delivery.