【Applicable material】Wood, branches, bark, furniture factory waste, building templates, wooden pallets, corn straw, wheat straw, rice husk, peanut shells, etc.

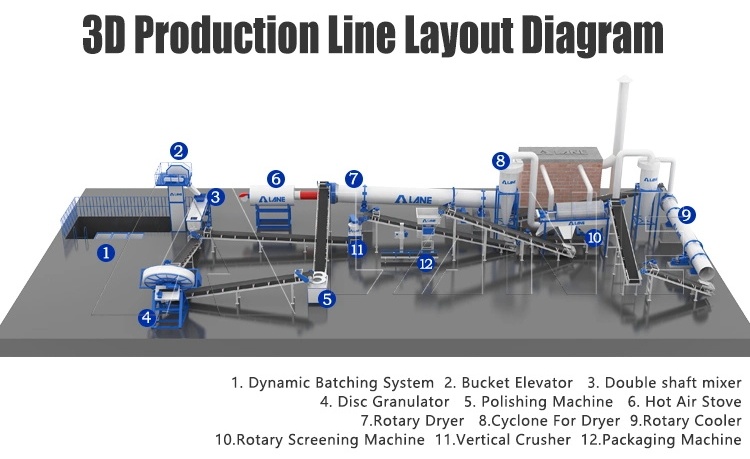

【Equipment 】Biomass crushers, pulverizers, biomass dryers, biomass pellet machines, pellet coolers, screening equipment, packaging machines, conveyors, dust removal equipment, etc.

Complete biomass pellet production line is a system composed of various equipment for processing pellet biomass energy. It includes chipping section, grinding section, drying section, pelletizing section, cooling section, screening and packing system. Depending on the biomass raw materials used, the equipment used will vary.

According to different raw materials and different customer needs, the biomass pellet production line is quite different.

Slicing: Agricultural and forestry waste enters the warehouse through a transporter, is sliced by a slicer, and then enters the wood chip warehouse. It is screened through a vibrating screen to screen out uniform wood chips, and then enters the water washing section.

Removal of impurities: The impurity removal system cleans the wood chips cut into specifications to remove mud, sand and other impurities contained in the wood chips to ensure the purity of the biomass pellet molded fuel and increase the calorific value of the fuel.

Proportion: Different raw materials are mixed in a certain proportion.

Drying: The hot air oven drying used in the traditional process is difficult to control the moisture and has a large error. High-temperature flue gas is used as the heating medium, and the moisture control error is within 0.01. Due to the precise control of fiber moisture, the quality and output of biomass pellet molding fuel are guaranteed.

Grinding: The raw materials are fully crushed through the crushing system to facilitate the next step of granulation.

Granulation: The raw materials used in biomass compression molding are various agricultural and forestry wastes such as wood, sawdust, sawdust, fruit shells, and straw. These biomass cells contain a large amount of cellulose, hemicellulose and lignin, accounting for more than 2/3 of the plant body components.

When the temperature reaches 70-110°C, the lignin softens and the adhesion force increases; at 200-300°C, the degree of softening intensifies. At this time, external pressure is applied to bond and combine to form a biomass molded block with a certain shape.

Since inelastic or viscoelastic fiber molecules are entangled and twisted with each other, they will not return to their original structural shape after the external pressure is removed.

Then through cooling-screening-quality inspection-packaging and other processes, the biomass pellet fuel is compressed and molded.

For more information, please contact us by sending an inquiry today! We can help you!