A continuous carbonization furnace is a device that uses various carbon containing wooden materials such as sawdust, peanut shells, rice husks, nut shells, coconut shells, palm shells, wood blocks, and coal materials to undergo dry distillation and anaerobic carbonization under conditions through a drum carbonization furnace.

The basic process of a continuous carbonization furnace is preheating, feeding, and discharging carbon. It is called a continuous carbonization furnace because after the preheating of the carbonization furnace is completed, the feed continuously enters the carbonization furnace and the carbon is continuously discharged. The carbonization time is about 30 minutes, which is carried out during the operation of the carbonization furnace. It can carbonize for 24 hours and the equipment can run for 5-6 days each time it is started.

There are many raw materials that can be carbonized in a continuous carbonization furnace, including biomass, sludge, garbage, and other types of materials. Raw materials with a size less than 2 cm and a moisture content of less than 15% can be directly carbonized. Raw materials with a size greater than 2 cm need to be processed using a crusher to a size less than 2 cm, and those with a moisture content greater than 15% need to be paired with a drying furnace.

Biomass:

Rice husks, straw, coconut shells, palm shells, bamboo, sawdust, sugarcane bagasse, distiller’s grains, olive shells, coffee shells, fruit shells, hazelnut shells, sawdust, oak, jute stems, peanut shells, sunflower stems, peach pits, etc.

Sludge:

Municipal sludge, river sludge, industrial sludge.

Domestic garbage:

Urban household waste.

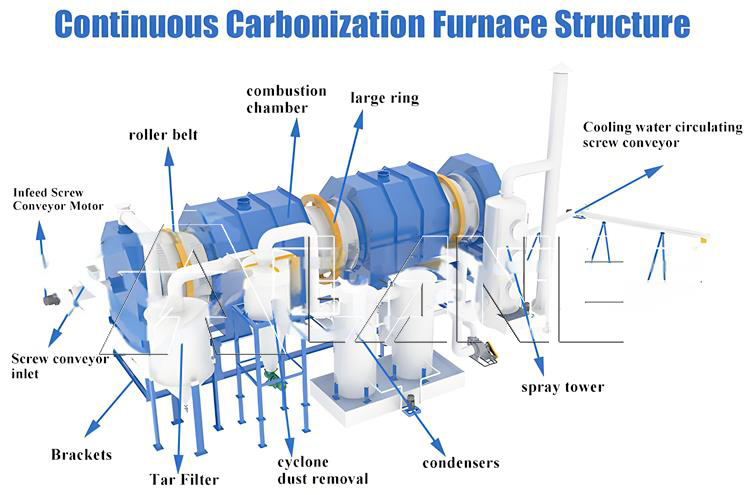

After the raw materials enter the main carbonization furnace, they move horizontally under the action of the guide vanes as the main carbonization furnace rotates, gradually moving from the feed inlet to the carbon outlet and being carbonized during the movement process. After feeding and discharging carbon, there are air seals to isolate the air, and at the same time, the induced draft fan of the carbonization main furnace is used to achieve a lean oxygen environment in the main furnace during continuous feeding and discharging processes.

After the continuous carbonization furnace material is carbonized, it falls into the carbon discharge spiral device at the carbon outlet. The carbon is rapidly cooled from high temperature to around 40 ° C through water cooling and heat exchange in the carbon discharge spiral device, thus achieving carbon discharge during equipment operation.

The production process of carbon/gas/oil co production has been realized, solving the traditional defects of high energy consumption/pollution/low efficiency. During the carbonization process, tar/wood vinegar and combustible gases are all recovered by equipment for reuse.

For more information, please contact us by sending an inquiry today! We can help you!

World-class and Energy-saving Operation, Factory Price & Fast Delivery.