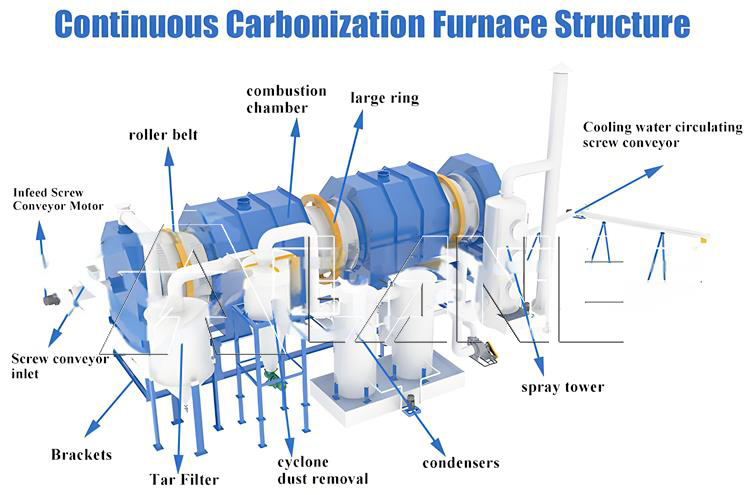

Sawdust carbonization furnace, also known as continuous carbonization equipment, is used to convert carbon containing wood or agricultural waste into carbon powder at high temperatures. The raw materials undergo destructive distillation process in an anaerobic environment to achieve high carbonization. The required materials must be less than 10mm, such as sawdust, rice husks, peanut shells, plant straw, bark, and ground coconut shells.

The working process of a sawdust carbonization furnace is to carbonize sawdust through a series of steps.

Firstly, it is necessary to process the wood chips of the raw materials, cut them into corresponding sizes, and clean them thoroughly to ensure the smooth progress of subsequent processes. Next, the processed wood chips are placed into a carbonization furnace, and the temperature of the sawdust carbonization furnace needs to be controlled within an appropriate range, usually between 400 ° C-500 ° C, in order for the carbonization process to proceed smoothly. During the carbonization process, it is necessary to control the oxygen concentration of the carbonization furnace to avoid the combustion of wood chips, which may affect the subsequent process results.

After carbonization treatment, wood chips will produce carbonized materials and smoke. Charcoal, also known as charcoal, is one of the main products produced during the carbonization process. And the smoke needs to be treated before it can be discharged. When dealing with flue gas, it is necessary to remove pollutants through purification equipment to ensure that flue gas emissions meet environmental requirements. At the same time, the flue gas collected in the purification equipment also contains a certain amount of organic matter, which can be used for power generation or heat recovery, thus achieving the goal of resource recycling.

For more information, please contact us by sending an inquiry today! We can help you!

World-class and Energy-saving Operation, Factory Price & Fast Delivery.