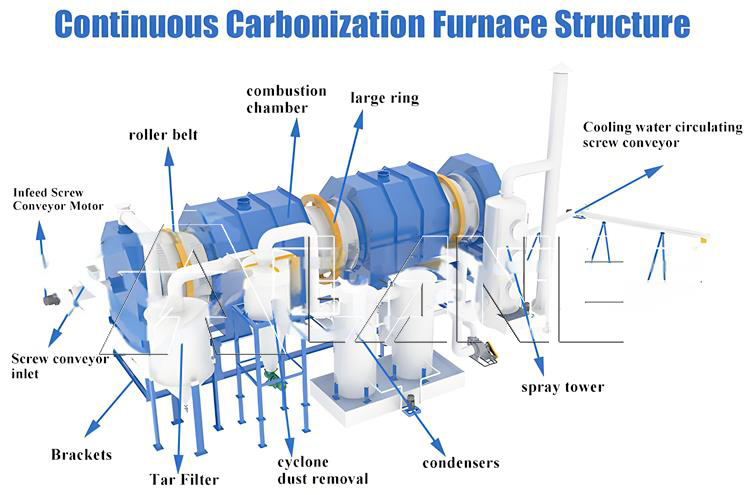

Continuous carbonization furnace is an efficient and energy-saving industrial equipment, mainly used for carbonization treatment of biomass materials such as straw, wood, bamboo, etc. Compared with traditional intermittent carbonization furnaces, continuous carbonization furnaces have significant characteristics in design and working principles, which make them more efficient and environmentally friendly in practical applications.

Working principle

Continuous drum carbonization furnace: The continuous drum carbonization furnace uses pyrolysis technology to achieve continuous carbonization of organic waste by controlling the temperature and atmosphere inside the furnace. The production process includes drying, pyrolysis, and cooling stages, and the entire process is continuous without the need for shutdown, cooling, or reheating.

Traditional carbonization furnace: Traditional carbonization furnaces often use batch processing, which involves filling materials and carbonizing them. After completion, they need to be cooled and reheated, resulting in production interruption and energy loss.

Production efficiency

Continuous drum carbonization furnace: Due to the use of continuous production mode, the time for cooling and heating is saved, and the production efficiency of continuous drum carbonization furnace is significantly improved, which can sustain 24-hour uninterrupted production.

Traditional carbonization furnace: The production efficiency of traditional carbonization furnaces is relatively low, and after each carbonization, they need to wait for the equipment to cool down and heat up again, resulting in additional time costs and energy consumption.

Energy conservation and environmental protection

Continuous drum carbonization furnace: The continuous drum carbonization furnace is designed with environmental protection and energy conservation in mind, equipped with sealing technology and heat recovery system to reduce heat loss and exhaust emissions. At the same time, the flue gas is treated to achieve standard emissions.

Traditional carbonization furnace: Traditional carbonization furnaces may produce a large amount of combustible gases such as carbon monoxide and methane during the carbonization process. If not effectively treated, it not only pollutes the environment but also wastes valuable energy.

Operational convenience

Continuous drum carbonization furnace: The continuous drum carbonization furnace adopts an automated control system, and the operator can easily monitor the entire carbonization process, reducing the difficulty of operation and maintenance costs.

Traditional carbonization furnace: Traditional carbonization furnace operation relies heavily on manual labor, and the operation process is relatively cumbersome, requiring high skills from operators.

Scope of application

Continuous drum carbonization furnace: Due to its high efficiency, environmental friendliness, and automation, continuous drum carbonization furnace is more suitable for large-scale and continuous production needs, such as large-scale carbonization of agricultural and forestry waste.

Traditional carbonization furnace: Due to its simple structure and low investment cost, although it is suitable for small-scale and intermittent production needs, its application scope is limited by its shortcomings in production efficiency and environmental protection.

When choosing a carbonization furnace, the following points should be considered:

Production scale and continuity requirements.

Acceptable environmental emission standards.

Investment budget and operating costs.

Characteristics of raw materials and requirements for carbonization quality.

Overall, the continuous drum carbonization furnace is significantly better than traditional carbonization furnaces in terms of production efficiency, energy conservation and environmental protection, ease of operation, and applicability. With the development of technology and the improvement of environmental awareness, continuous drum carbonization furnaces will increasingly become the preferred equipment in the carbonization industry, especially in large-scale production, and their performance is worth looking forward to.

If you have any further inquiries, please feel free to consult our company at any time.