Animal manure creates greenhouse gas if not treated properly. A high-efficiency animal manure to organic fertilizer production line transforms this waste into a profitable venture. Getting rid of animal manure is costly, but it is also an opportunity. An animal manure to organic fertilizer production line integrates advanced automation, flexible processing, and engineering to create highly nutrient organic fertilizer that provides nutrients to plants.

LANE Heavy Industry, a professional manufacturer of organic fertilizer machinery, has developed a high-efficiency animal manure to organic fertilizer production line that integrates advanced technology, stable performance, and humanized design. LANE’s Organic Production Line reduces labor costs, improves production efficiency, and ensures stable fertilizer quality.

Table of Contents

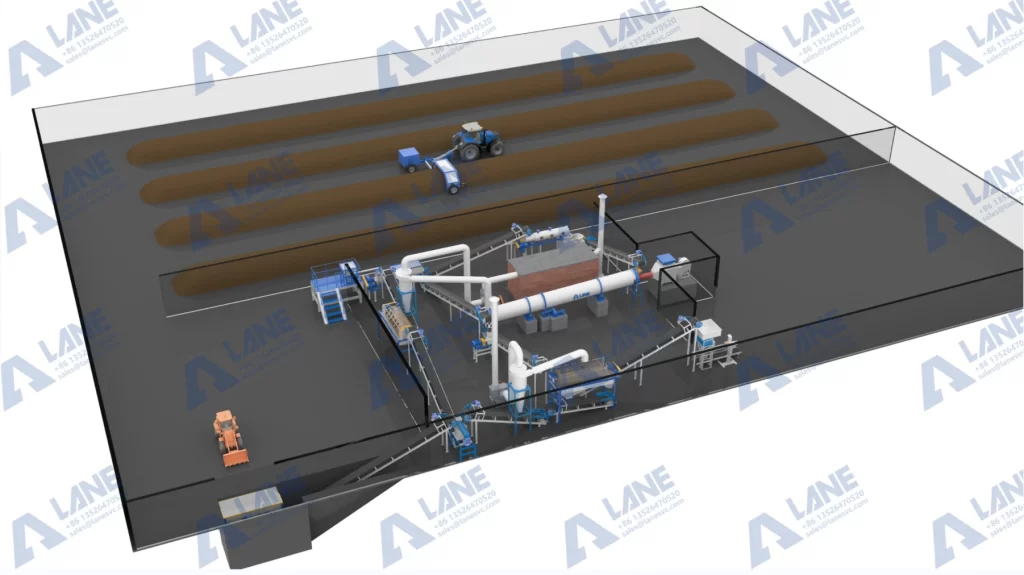

An animal manure to organic fertilizer production line is a coordinated sequence of multiple machines that complement each other. Lane Heavy Industry’s production line guides raw materials through eight critical stages:

The entire animal manure to organic fertilizer production line can be managed with a centralized Programmable Logic Controller (PLC) system. This high level of automation ensures consistent product quality, reduces human error, and lowers labor costs.

The fermentation process should be efficient and controlled. It is necessary for quality and hygiene maintenance. LANE offers specialized crawler compost turners and fermentation tanks for this process. These systems create the ideal aerobic environment for microorganisms by controlling temperature, moisture, and oxygen levels. This process kills harmful bacteria and pathogens, stabilizes nutrients, and converts raw manure into a safe, nutrient-rich organic base material. Investing in a dedicated, high-efficiency fermenter accelerates this process and provides a consistent feedstock for the rest of the animal manure to organic fertilizer production line.

At LANE we do custom design according to the raw material, climate, land, and capacity. No two operations are identical. A key feature of a modern animal manure to organic fertilizer production line is its flexibility. LANE systems are engineered to be modular and customizable. This design allows the buyer to configure a line that matches their specific needs.

You can build your animal manure to organic fertilizer production line at a manageable scale and expand as your business grows without replacing the whole production line.

Operating in an abrasive, corrosive, and humid environment demands robust construction. High-efficiency lines use corrosion-resistant materials like stainless steel in critical components to ensure long-term durability with minimal downtime. Integrated environmental protection systems, such as pulse dust collectors and deodorizing units, are essential for worker safety, meeting regulatory standards, and maintaining community relations. LANE animal manure to organic fertilizer production lines have up to 5 years of warranty and comprehensive after-sales support. We provide installation guidance and operator training to ensure long-term reliability.

What is the typical production capacity range for a complete line?

Capacity is highly customizable. Lane Heavy Industry’s PROM production lines, for example, offer a range from 3 to 20 tons per hour, with other industrial lines capable of up to 30 tons per hour. The capacity of your specific animal manure to organic fertilizer production line will be configured based on your raw material volume and business goals.

Can the production line handle different types of animal manure?

Yes, a well-designed system is versatile. The equipment can process manure from chickens, cows, pigs, sheep, and other livestock, often in combination with other organic wastes like crop straw or municipal sludge. The initial fermentation and mixing stages are adjusted to accommodate these different materials.

How automated is the operation, and what technical support is provided?

These lines are designed for high automation, often controlled by a central PLC system that manages the entire process from mixing to packaging. As a manufacturer, Lane provides full-service support, including pre-sales consultation, on-site or video instruction for installation, and training for your workers to operate the animal manure to organic fertilizer production line effectively.

What are the key certifications and environmental features?

Reputable manufacturers ensure their equipment meets international standards such as CE and ISO certification. Environmental features are built into the design, including enclosed fermentation systems to control odor, dust collection units, and energy-efficient motors to minimize the overall environmental footprint of the operation.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520