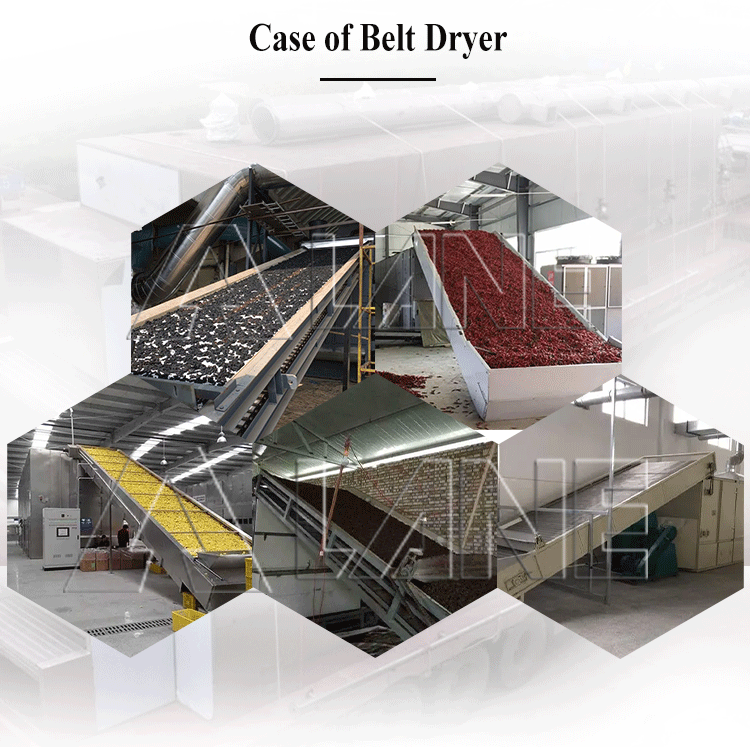

Fertilizer belt dryer is a kind of equipment used for drying fertilizer, which is widely used in agriculture, chemical industry and other fields. This kind of equipment usually uses mesh belt as the transmission medium, and evenly heats and dries the material through the hot air circulation system, so as to achieve the purpose of reducing the moisture content.

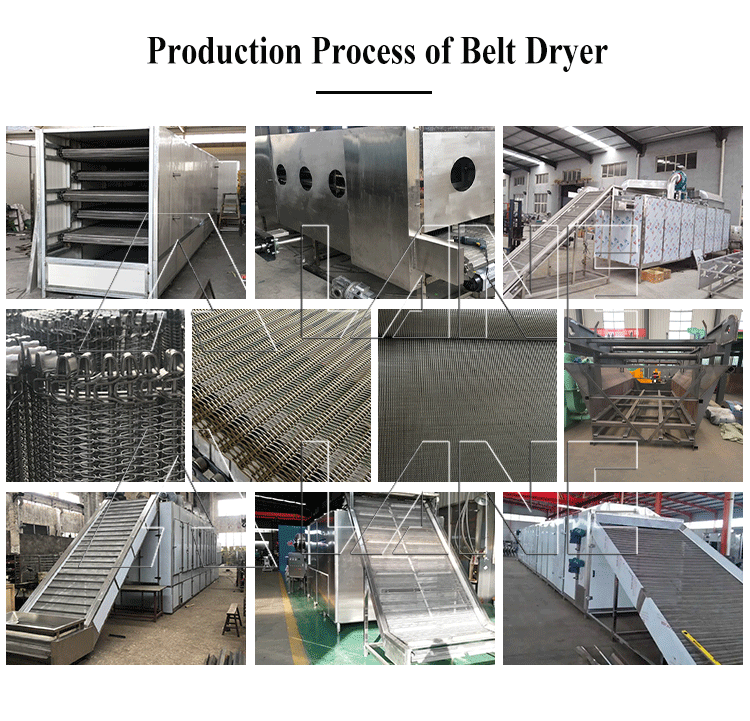

The belt dryer produced by LANE can be designed as a single-layer or multi-layer structure according to different needs. The multi-layer design can improve the drying efficiency and is suitable for large-scale production.

Belt Dryer |

||||||

|---|---|---|---|---|---|---|

| Model | Drying Time(t) | Drying Section Length(m) | No. Of Units | Heat Transfer Area(m³) | Total Power(kw) | Total Weight(kg) |

| LA-DW-1.2-8 | 0.2-1.2 | 8 | 4 | 272 | 11.4 | 4800 |

| LA-DW-1.2-10 | 0.25-1.5 | 10 | 5 | 340 | 13.6 | 5780 |

| LA-DW-1.6-8 | 0.2-1.2 | 8 | 4 | 352 | 11.4 | 5400 |

| LA-DW-1.6-10 | 0.25-1.5 | 10 | 5 | 44 | 13.6 | 6550 |

| LA-DW-2-8 | 0.2-1.2 | 8 | 4 | 448 | 19.7 | 6350 |

| LA-DW-2-10 | 0.25-1.5 | 10 | 5 | 560 | 23.7 | 7800 |

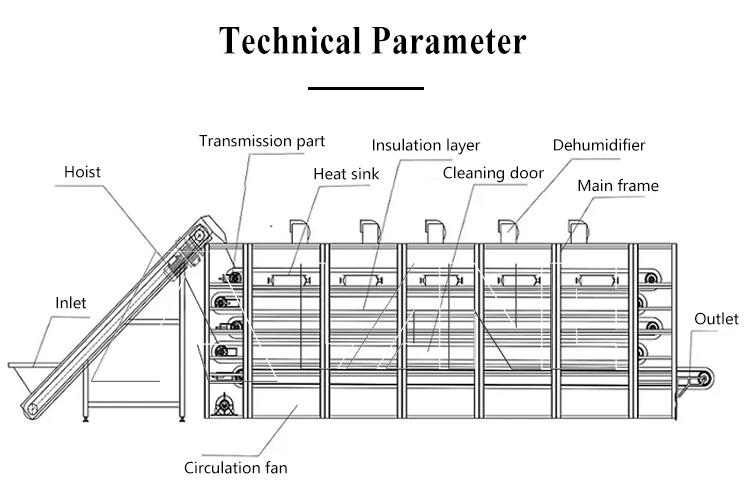

The fertilizer belt dryer is mainly composed of a trailer, a transmission system, a drying cylinder, a hot air furnace, a control system and other parts. The trailer supports the entire equipment, and the transmission system includes a motor, a reducer, a V-belt and a gear transmission mechanism, which are used to drive the rotation of the drying cylinder. A lifting plate is welded on the inner wall of the drying cylinder. The material is lifted and thrown in the cylinder as the cylinder rotates, and fully contacts with the hot air for heat exchange, thereby achieving a drying effect.

The hot air furnace provides high-temperature hot air, which is introduced into the drying cylinder through a fan to form a hot air flow, so that the material is evenly heated. In addition, the equipment is also equipped with a control system for adjusting the temperature, humidity and mesh belt speed to ensure the stability and uniformity of the drying process.

The material is evenly spread on the mesh belt through the feeder, and the mesh belt is driven by the transmission device to move back and forth in the belt dryer. The hot air enters from the top or bottom of the dryer, passes through the material layer, takes away the moisture and is discharged through the dehumidification system. During the drying process, the material is continuously lifted and thrown by the lifting plate to increase the contact area with the hot air and improve the drying efficiency. Finally, the dried material is discharged from the other end of the dryer.

The fully automatic belt dryer is equipped with multiple groups of heating and ventilation systems according to different production outputs. Each group includes an air inlet fan, a heat exchanger, a steam inlet pipe, a condensate pipe, a temperature control electronic control and a matching air duct.

The top-mounted heat exchanger equipped with a centrifugal fan is made of all stainless steel.

The temperature is controlled by partitions to ensure the degree of heating of the material.

The conveying speed of the belt dryer is adjusted by a frequency converter, and the humidity and temperature control parameters are set automatically.

The inlet and outlet are equipped with a turning device to ensure the uniformity of the material, and a detachable middle turning device can be added as needed.

An independent control cabinet is used, and parameters can be set separately, which is easy to operate.

For more information, please contact us by sending an inquiry today! We can help you!

Advantages:

1. Fast drying speed and high evaporation intensity

The material is evenly spread on the mesh belt, hot air flows through the material, water vapor isdischarged firom the dehumidification holes, the evaporation intensity is large, and the dryingspeed is accelerated.

2. High efficieney and good product quality

The equipment itself’ is equipped with a spreading device, which improves the quality of the equipment and produets for drying materials.

3. Standardized production, the number of sections can be increased according to the output.

The length of the box body is composed of’standard sections. and the dryer can be made into amulti-layer type according to needs.

World-class and Energy-saving Operation, Factory Price & Fast Delivery.