Introduction

In the current context of low-carbon agricultural development, the benefits of organic fertilizer production lines are becoming increasingly prominent, and they have become an important research direction for agricultural production development.

The benefits of organic fertilizer production lines mainly lie in their wide raw material sources, environmental friendliness, and positive impacts on soil health, crop growth, and environmental protection.

Chicken manure, as a widely available agricultural by-product, has great potential for application in organic fertilizer production lines. However, its effective utilization still faces a series of technical obstacles.

This article focuses on discussing the benefits of the organic fertilizer production line, evaluating the potential of chicken manure as a key raw material, and analyzing the key technologies of the organic fertilizer production line.

Through the exploration of these three key aspects, the aim is to provide reference and guidance for improving the efficiency of the utilization of agricultural waste resources and promoting the sustainable development of the organic fertilizer production line.

benefits of organic fertilizer production line

As a sustainable and environmentally friendly alternative, the benefits of organic fertilizer production lines hold significant importance in modern agriculture. Beyond improving soil health and increasing crop yields, these benefits also extend to environmental protection and the promotion of sustainable agricultural systems.

This section will outline the functional characteristics and economic value of organic fertilizer production lines in agricultural applications.

Improve soil health

The benefits of organic fertilizer production line lie in improving soil health. The produced fertilizers are rich in organic matter and play a crucial role in enhancing the physical, chemical and biological properties of the soil.

By increasing soil porosity, enhancing water retention capacity and promoting air circulation, it creates favorable conditions for the healthy development of root systems. Moreover, such fertilizers can also promote the growth of beneficial soil microorganisms, thereby increasing microbial activity and the overall fertility of the soil.

Improve the quality of crops

The benefits of organic fertilizer production line are particularly evident in improving the quality of crops. Unlike chemical fertilizers, the fertilizers produced by the organic fertilizer production line can slowly and continuously release nutrients, ensuring that crops receive balanced nutrition at all growth stages.

This slow-release characteristic helps plants grow stably and contributes to improving the quality of agricultural products. For instance, fruits and vegetables grown with fertilizers produced by the organic fertilizer production line usually have higher sugar content, vitamin content, and essential mineral content.

Reduce environmental impact

The benefits of organic fertilizer production line are particularly prominent in terms of environmental protection. Excessive use of chemical fertilizers leads to nutrient loss, water body eutrophication and soil degradation. In contrast, the fertilizers produced by the organic fertilizer production line release nutrients at a slower rate, significantly reducing nutrient loss and runoff, thereby alleviating the environmental burden.

Moreover, the organic fertilizer production line can convert agricultural by-products and waste into resources, reducing pollution and promoting the development of circular agriculture.

Support sustainable agriculture

The benefits of organic fertilizer production line also lie in its support for sustainable agriculture. Its promotion and application are highly consistent with the concept of sustainable development. It not only can restore and maintain soil fertility, but also can reduce the reliance on chemical fertilizers, thereby lowering production costs in the long run.

Moreover, converting organic waste into fertilizer helps with resource recycling and the effective utilization of biomass, alleviating the pressure on natural resources.

Economic benefits and long-term benefits

The organic fertilizer production line also shows remarkable economic benefits. Although the initial investment for the organic fertilizer production line may be relatively high, its long-term economic benefits are significant. The improvement of soil structure, the enhancement of crop quality, and the reduction of environmental damage will eventually translate into increased income for farmers. Moreover, the organic fertilizer production line can effectively handle rural organic waste, create job opportunities, and promote local economic development.

The potential advantages of using chicken manure as raw material for the organic fertilizer production line

High nutritional content and rapid degradability

Chicken manure is rich in nitrogen, phosphorus, potassium and organic matter, and its nutritional content is significantly higher than that of other livestock manures. Its low carbon-to-nitrogen ratio is conducive to the rapid decomposition by microorganisms, further highlighting the advantages of the organic fertilizer production line and making it an ideal raw material for efficient composting.

Significant agricultural and environmental benefits

The organic fertilizer production line products made from chicken manure can increase crop yields by 12-18%, improve crop quality, and enhance the activity of soil microorganisms. These benefits fully demonstrate the practical application value of the advantages of the organic fertilizer production line.

Key technologies of the organic fertilizer production line

Pre-treatment technology

1.Raw material screening and impurity removal: Using vibrating screens and magnetic separators to remove stones, metallic impurities and plastics from the raw materials, ensuring the purity of the raw materials.

2.Crushing and Mixing: Use a hammer crusher to crush large particle materials such as straw into pieces ranging from 2 to 5 mm. Then, use a mixer to evenly mix them, and adjust the carbon-to-nitrogen ratio to 25-30.

3.Water regulation: Use spraying or drying equipment to control the moisture content of the raw materials to be 50-60%, creating suitable conditions for the subsequent fermentation process.

Fermentation technology

Aerobic fermentation process:

Valve-type fermentation: Using a continuous turning machine, the temperature is maintained at 55-65℃ for 5-7 days to kill pathogenic bacteria.

Wind pile fermentation: Suitable for small-scale production. The pile should be turned over once every 1-2 days, and the fermentation period lasts for 15-20 days.

Application of inoculants: By applying strains such as Bacillus subtilis and Trichoderma, the degradation of organic matter can be accelerated, and ammonia volatilization loss can be reduced.

Intelligent Monitoring: Utilizing Internet of Things technology to monitor temperature, humidity and oxygen concentration in real time, optimizing fermentation conditions.

Granulation Technology

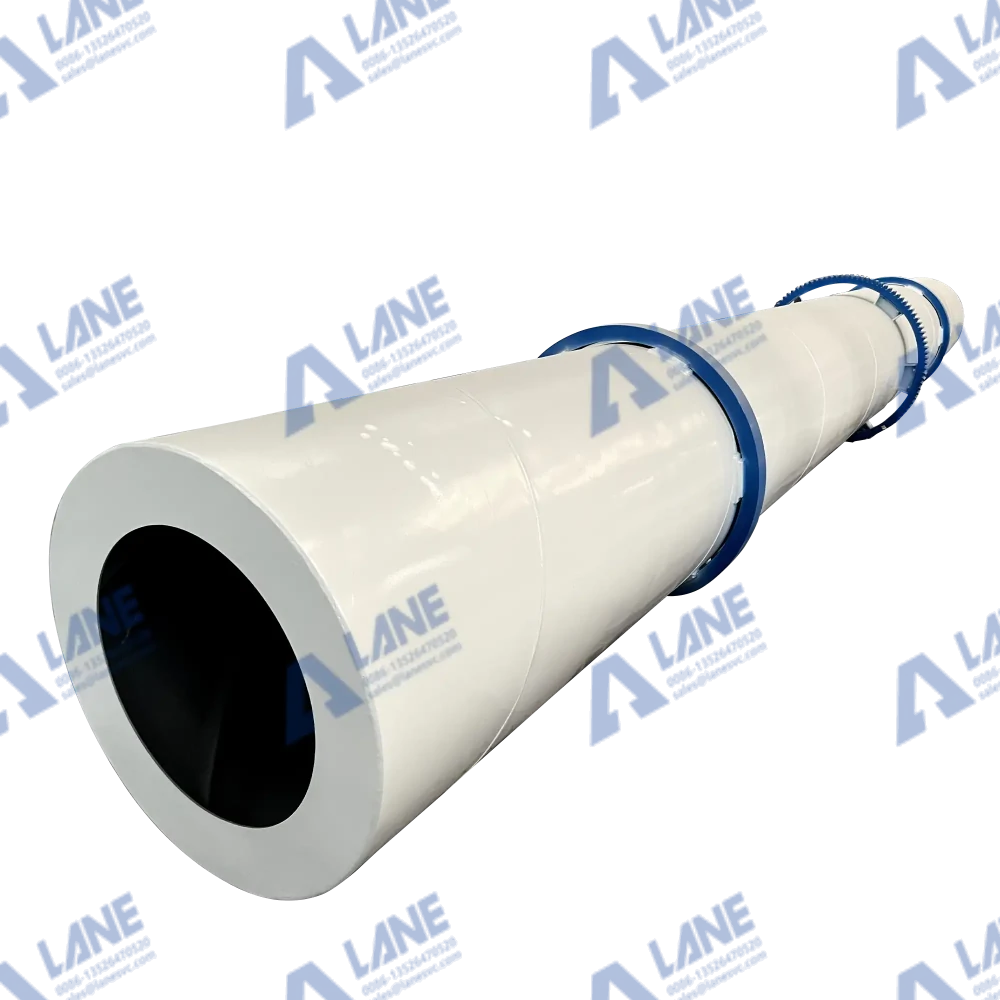

Granulation is a crucial step in the organic fertilizer production line, directly influencing the uniformity and strength of the particles. The following introduces three common granulation equipment and their characteristics:

The device adopts a tilted disc structure and uses the rolling method for granulation. It is suitable for small and medium-sized organic fertilizer production lines, with a granulation rate of over 85%. The moisture content of the material should be controlled within 20-30%, and adhesives can be added to enhance the particle strength.

It adopts a drum structure and uses rolling and squeezing methods for granulation. It is suitable for large-scale organic fertilizer production lines, with good particle uniformity and high production efficiency. The moisture content of the material should be controlled within 15-25%, and the rotation speed of the drum needs to be adjusted to achieve the best results.

It consists of a stirring shaft, stirring teeth and a granulation chamber. It is suitable for high-fiber raw materials. The granulation rate exceeds 90%, and the particle size range is 3-8mm. The moisture content of the material should be controlled within 20-35%. Bentonite or humic acid can be added as a binder. The stirring speed is usually 200-400 rpm.

Drying and cooling process

Drying process: Use a drum dryer with the temperature controlled at 80-100℃ to reduce the moisture content of the particles to below 15%.

Cooling treatment: Use a counter-flow cooling tower to reduce the particle temperature to room temperature, preventing agglomeration during subsequent packaging.

Packaging and Warehousing Technology

Automated packaging: We use a quantitative packaging machine with a capacity of 25-50 kilograms per bag. The error is controlled within ±0.2 kilograms.

Warehouse Management: The finished products should be stored in a cool and dry place, avoiding direct sunlight and high humidity conditions. The shelf life can last up to 12 months. Summary

The benefits of the organic fertilizer production line play a crucial role in modern agriculture. Its products can improve soil quality, increase crop yields, reduce environmental pollution and enhance microbial activity.

Take chicken manure as an example. Through scientific organic fertilizer production line technology, agricultural waste such as chicken manure is efficiently converted into high-quality organic fertilizer. This process fully demonstrates the advantages of the organic fertilizer production line and achieves the dual goals of resource recycling and sustainable development of agriculture.

In the long run, with the advancement of technology and the development of intelligent systems, the advantages of organic fertilizer production lines will become even more prominent, providing strong support for the sustainable development of agriculture.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520