Brand: LANE

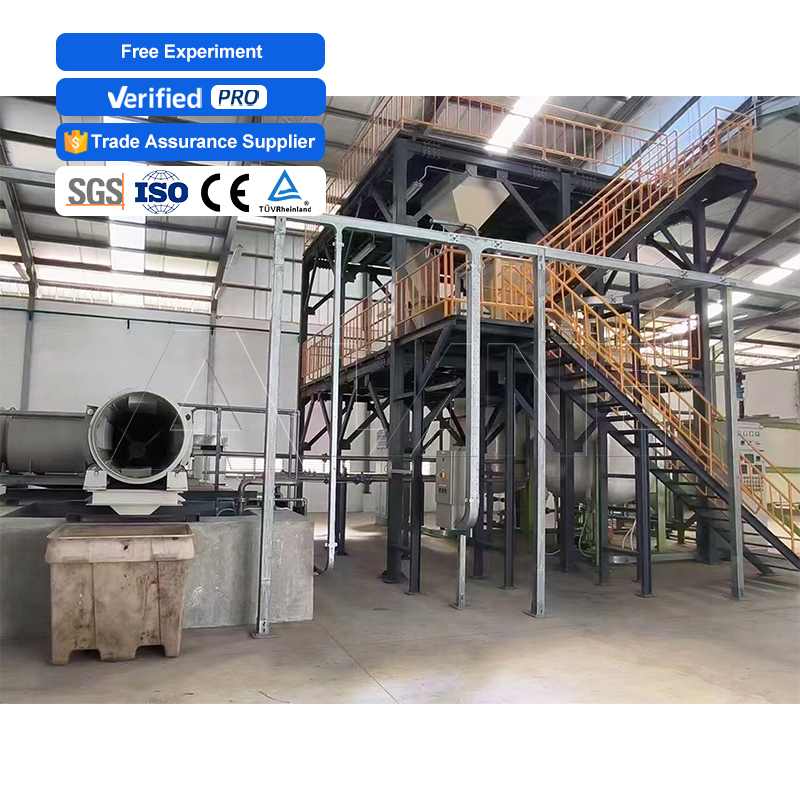

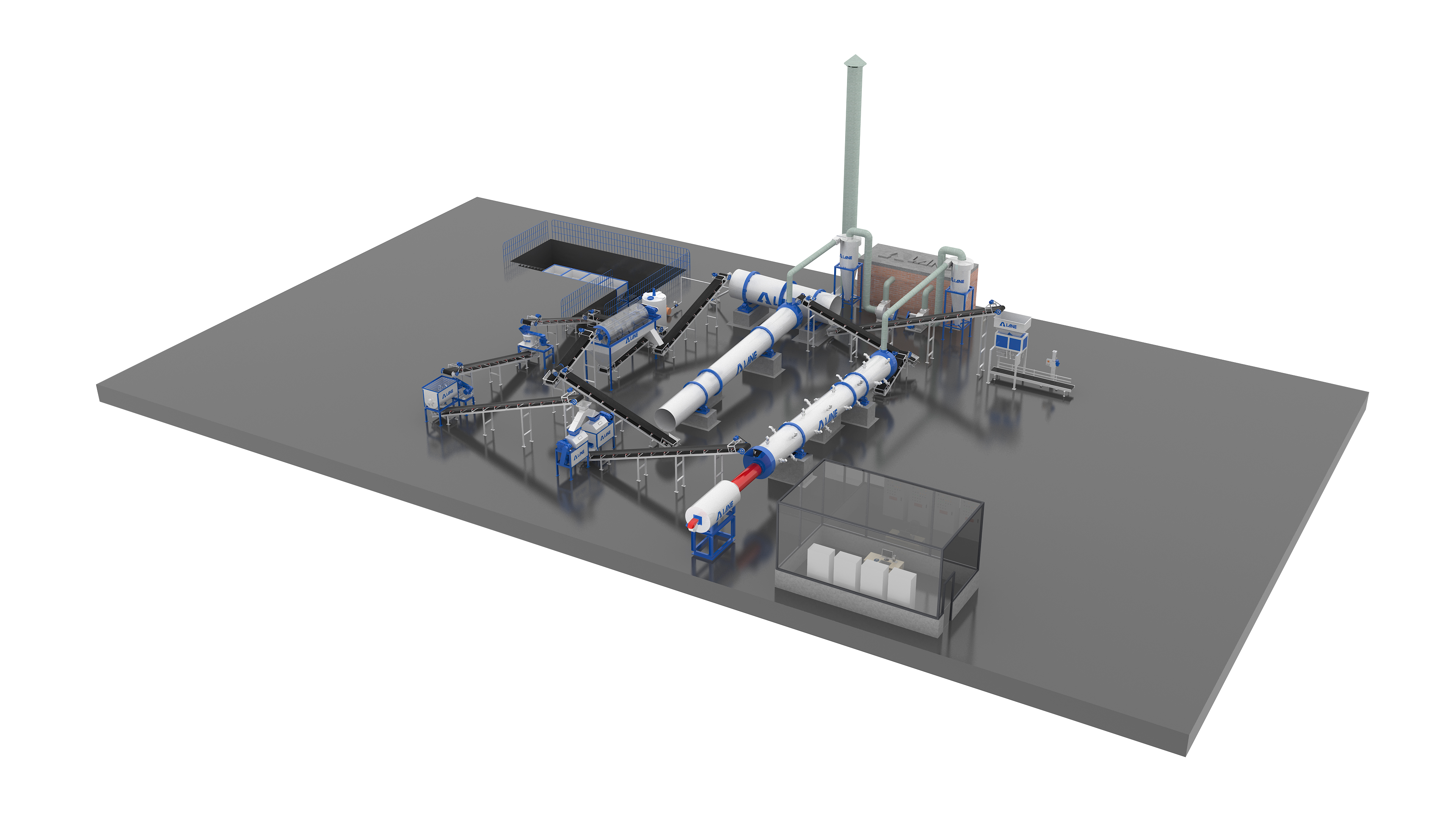

Production line advantages:

Large output, small footprint, relatively low cost, PLC fully automatic control.

Applicable materials:

The three elements of nitrogen, phosphorus and potassium, organic acid solution carrier, medium and trace element fertilizers, etc.

Warranty: 5 Years

Delivery Time: Within 45 days

Bio-liquid fertilizer production line is a complete set of equipment for producing liquid fertilizer. Common raw materials include ammonium nitrate, urea, phosphoric acid, potassium hydroxide and various trace nutrient solutions. LANE‘s Bio-liquid fertilizer production line has a simple structure and convenient operation. It is suitable for most liquid fermentations, and the equipment has good stability and corrosion resistance.

For more information, please contact us by sending an inquiry today! We can help you!

You can click on the numbers to see detailed pictures!

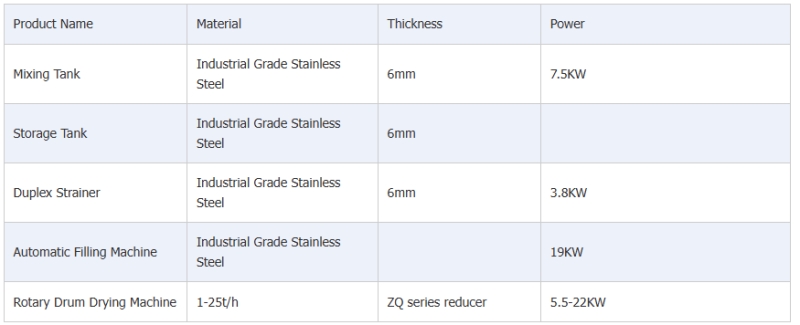

The following are the product parameters used in the production line:

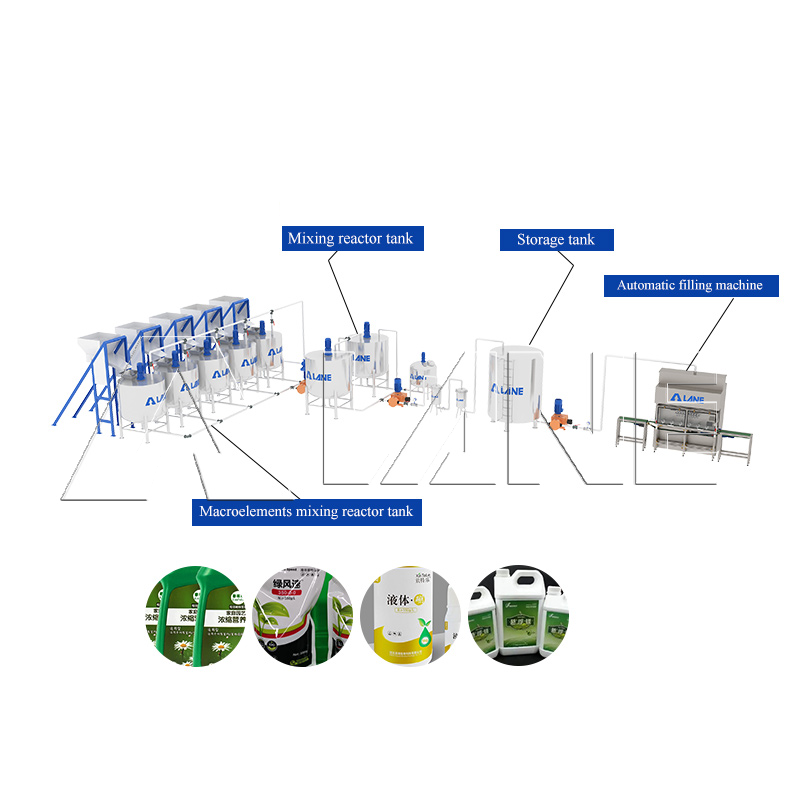

Raw Materials Storage and Handling:

Storage Tanks or Silos: used to store raw materials such as ammonium nitrate, urea, phosphoric acid, potassium chloride and other nutrients.

Conveyors: transport raw materials from storage to mixing areas.

Mixing and Dissolving:

Mixing Tanks or Reactors: dissolve and mix raw materials in water to form liquid fertilizer solution.

Agitators or Mixers: ensure that raw materials and water are evenly mixed.

Filtration and Separation:

Filters: remove impurities and solid particles from liquid fertilizer solution.

Separators: separate remaining solid particles or unwanted materials.

Packaging and Filling:

Filling Machines: fill liquid fertilizer into containers such as bottles, cans, drums or bulk tanks.

Labelers: label containers with product information.

Storage and Distribution:

Storage Tanks: used to store and distribute finished liquid fertilizers.

Finished product samples