Farmers have been relying on chemical fertilizers to apply on the soil to get bountiful harvests. But this model has its limits. Chemical fertilizer has depleted soil organic matter, harmed microbial life, and created a cycle of dependency. This is where bio-organic fertilizer production has become a game-changer. Forward-thinking farmers are now turning to circular bio-organic fertilizer production.

Bio-organic fertilizer production converts organic waste into nutrient-rich, microbe-enhanced fertilizers. It is giving way to green practices driven by ecological concerns and food safety demands. By using bio-organic fertilizer, farmers can close the loop on their operations, reduce input costs, and build unparalleled soil health. This article explains how a modern bio-organic fertilizer production line by LANE Heavy Industry empowers this transition, turning waste into wealth while aligning with global sustainability goals.

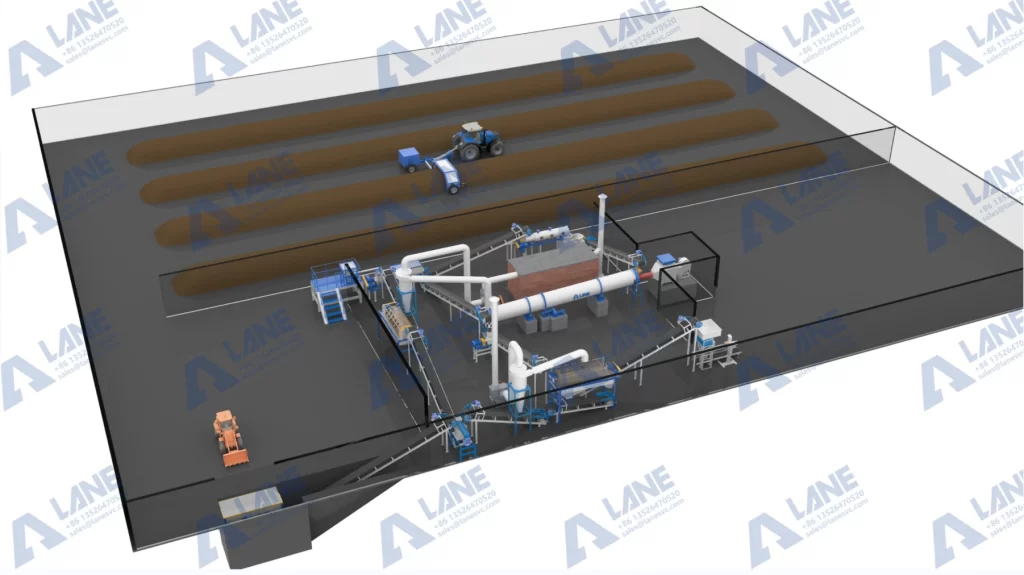

An effective bio-organic fertilizer production requires precise, efficient machinery to create a high-quality, marketable product. Consistently, LANE Heavy Industry’s bio-organic fertilizer production line is designed to handle this process from start to finish.

The production begins with fermentation. LANE Heavy Industry’s compost turners or fermentation tanks are crucial here. The compost turners systematically turn and aerate the long windrows of raw materials. This controls temperature and oxygen levels to ensure aerobic digestion by microbes while eliminating pathogens and weed seeds. Our crawler compost turner is designed with crushing functions to break down clumps, ensuring a uniform fermentation process that can achieve the required 60-70°C temperatures.

After fermentation, the fermented compost is piled for a curing process to stabilize the compost. After that, the cured compost enters the process phase. The LANE bio-organic fertilizer production line includes machines that systematically work with each other to create premium bio-organic fertilizer.

The table below summarizes the core advantages of this mechanized approach over traditional methods:

| Production Aspect | Traditional/Manual Methods | LANE Mechanized Production Line |

| Scale & Efficiency | Labor-intensive, limited by weather and space. | High-volume, continuous processing. A single line can process tens of thousands of tons of material annually. |

| Product Consistency | Variable quality, moisture, and nutrient content. | Produces uniform, granulated fertilizer with reliable analysis. |

| Process Control | Difficult to manage aeration, temperature, and hygiene. | Engineered for optimal aerobic fermentation, pathogen elimination, and dust control. |

| Economic Viability | High labor cost, low-value bulk product. | Creates a storable, transportable, premium product for on-farm use or commercial sale. |

The LANE production line transforms organic waste management from a disposal cost into a revenue stream through efficient bio-organic fertilizer production.

First, it cuts your input cost. By producing your own fertilizer, you protect your operation from the price volatility of synthetic fertilizers while establishing a stable bio-organic fertilizer production system. Raw materials can be sourced directly from your farm or nearby agricultural operations. The Rodale Institute’s Farming Systems Trial, a 40-year side-by-side study, found that organic systems consistently achieved lower operating costs than conventional farming.

Second, it creates a new product to sell. The high-quality, bio-organic fertilizer can supply your own needs and be sold to neighboring farms, horticultural businesses, or organic landscapers. This taps into a growing market driven by consumer demand and government initiatives.

Third, your farm becomes future-proof against regulation. Governments worldwide are incentivizing sustainable nutrient management to combat pollution. Producing and using your own bio-organic fertilizer positions your farm into an elite category.

Bio-organic fertilizer production builds systemic resilience. Organically managed soils have higher water infiltration rates and greater moisture-holding capacity.

This practice is the cornerstone of true soil health. Fertilizer produced by bio-organic fertilizer production continuously feeds the soil’s microbial ecosystem. This increases organic matter, improves structure, and enhances the natural nutrient cycle of the soil. Healthy soil is the ultimate asset for the farmer. It reduces erosion, provides natural disease suppression, and produces higher-quality produce.

Finally, it strengthens your brand. Consumers and food companies seek sustainably sourced ingredients. The ability to verify your closed-loop, soil-building practices is a powerful marketing tool. It will help your company secure access to premium markets.

Bio-organic fertilizer production is no longer a niche option but a necessity for farms aiming to thrive in a sustainable future. Investing in bio-organic fertilizer will help future-proof your farm. The future-proof farm doesn’t just harvest crops; it harvests the benefits of its own fertility cycle, ensuring productivity, profitability, and environmental stewardship for the long term.

Q: Is the fertilizer produced on-farm as effective as synthetic fertilizer?

A: Yes, when managed correctly. Long-term studies show organic systems can match conventional crop yields. The key advantage is that bio-organic fertilizers release nutrients slowly, improve soil structure, and feed microbial life, leading to more resilient plants and sustainable long-term yields.

Q: Can the machinery handle different types of raw materials?

A: Absolutely. Modern lines from manufacturers like LANE are designed to process a wide variety of organic wastes, including cattle, poultry, and swine manure, as well as crop straw, biogas residue, and other agricultural by-products. The initial fermentation and crushing stages are key to homogenizing these inputs.

Q: What is the typical payback period for this kind of investment?

A: The payback period varies based on scale, raw material availability, and local fertilizer prices. However, savings on purchased synthetic fertilizers, waste disposal costs, and potential revenue from selling surplus organic fertilizer can lead to a compelling return on investment. Government grants and subsidies for sustainable agriculture equipment in many regions can further shorten this period.

Q: Do I need special training to operate and maintain this equipment?

A: Reputable manufacturers provide comprehensive operational training and maintenance manuals. The systems are engineered for reliability, with many components being standard industrial parts for easier servicing. Many farmers find that a skilled team member can quickly become proficient in running the production line.

Q: How does on-farm production fit with organic certification?

A: It is an excellent strategy for certified or certifiable operations. Using your own composted livestock manure and crop residues is a core practice in organic standards. It ensures you have a guaranteed, cost-effective source of compliant fertility inputs, strengthening your organic system’s integrity.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520