In this era, environmental protection and food safety have become global priorities. Governments around the world are implementing policies that are slowly turning farmers towards green and sustainable fertilizers. It has become a powerful market force. At the heart of this green revolution lies bio organic fertilizer production. This sector is experiencing explosive growth. This growth is driven by consumer demand for cleaner food, regulatory pressures to reduce chemical use, and the urgent need for soil restoration. Starting a bio organic fertilizer production presents a commercial opportunity.

Bio organic fertilizer is made from agricultural wastes such as livestock manure and crop straw through microbial fermentation. It solves the problem of waste pollution, improves soil quality and promotes crop quality. LANE Heavy Industry, a professional manufacturer of agricultural machinery, provides a complete set of high-quality production lines to help entrepreneurs realize the commercial value of bio organic fertilizer production.

Unlike traditional compost, bio organic fertilizers are enriched with beneficial microorganisms (bacteria, fungi, actinomycetes). They are an active ingredient of the fertilizer. They fix atmospheric nitrogen, solubilize locked phosphorus and potassium, suppress soil-borne pathogens, and improve soil structure. This results in higher crop yields, improved plant health, and reduced dependency on synthetic inputs. This makes bio organic fertilizer a premium fertilizer. This product can command a premium price from organic farmers, vineyards, horticulturists, and even eco-conscious home gardeners.

A successful commercial bio organic fertilizer production operation follows a systematic process:

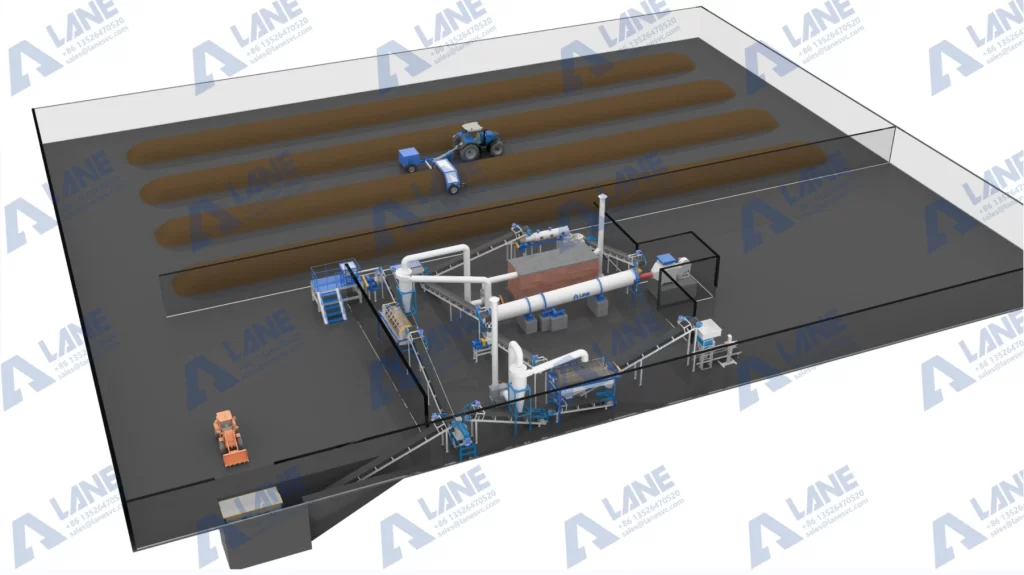

Efficiency, consistency, and scalability are non-negotiable for a profitable business. This is where LANE Heavy Industry gives you a competitive advantage. We offer integrated, turnkey solutions for bio organic fertilizer production, removing the guesswork and technical bottlenecks.

A typical LANE bio organic fertilizer production line includes:

By providing a synchronized line, LANE ensures that your bio organic fertilizer production is continuous, quality-controlled, and capable of meeting large-scale demand.

The profitability of bio organic fertilizer production depends on low-cost inputs and efficient processing. Raw materials are often waste products, available at minimal or negative cost. The major investments are in land, labor, and machinery.

Key Revenue Streams:

A well-designed LANE production line maximizes output while minimizing energy and labor costs. This accelerates the payback period. The ability to process large volumes consistently is what transforms waste into a high-margin product.

Managing an organic fertilizer production line is filled with challenges, including sourcing consistent raw material, managing odor during fermentation, and navigating local organic certification standards. An automatic LANE bio organic fertilizer production line addresses the first two with enclosed fermentation options and efficient process design.

There are lots of opportunities available for bio organic fertilizer production. You can partner with municipalities for waste diversion, contract with large food processors to handle their organic by-products, or develop branded region-specific formulas. The business of bio organic fertilizer production is uniquely positioned at the intersection of agriculture, waste management, and environmental technology.

Bio organic fertilizer production brings considerable economic benefits to entrepreneurs, makes positive contributions to environmental protection and food safety, achieving a win-win situation of economy and society. Entering the bio organic fertilizer production industry is more than starting a business. It offers a clear path to profitability while making a tangible environmental impact. With the help of a production line from LANE Heavy Industry, entrepreneurs can transform organic waste into a commercial product that rejuvenates our soils and grows a resilient, future-proof business.

Q1: What is the minimum space and investment required to start a bio organic fertilizer production business?

A: A small to medium-scale operation typically requires 1-2 acres of land for raw material storage, fermentation platforms, and machinery setup. Investment varies widely based on scale and automation, but a foundational LANE production line can start from a mid-range capital investment, with clear ROI models based on output.

Q2: How long does the complete bio organic fertilizer production cycle take with modern machinery?

A: Using traditional composting, the process can take 3-6 months. With a LANE aerobic fermentation system, the active fermentation phase is reduced to 15-20 days. The entire process from raw waste to bagged product can be accomplished in 4-5 weeks, significantly increasing your annual production capacity.

Q3: Can I produce different grades or formulas of bio organic fertilizer on one production line?

A: Absolutely. This is a major advantage of an integrated line. By adjusting the raw material mix (e.g., poultry manure vs. plant-based compost) and adding different microbial inoculants during the blending stage, you can produce specialized formulas for vegetables, fruits, turf, or flowers all on the same LANE machinery.

Q4: Is the bio organic fertilizer produced this way truly “organic”?

A: The process itself aligns with organic principles, utilizing natural materials and biological processes. For the final product to be certified organic for use in certified organic farming, it must be produced from approved input materials and often undergo certification from a recognized body (like OMRI or USDA NOP). Your machinery provider, like LANE, ensures the process doesn’t introduce contaminants.

Q5: Why is granulation important in commercial bio organic fertilizer production?

A: Granulation reduces dust, improves handling and storage, allows for precise mechanical application by farmers, and enhances the product’s marketability. A granulated product is often perceived as more professional and high-value than a powder, allowing you to command a better price in the market.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520