Burner is a system that uses biomass as fuel and generates heat energy through efficient combustion technology for drying various agricultural products and biomass fuels. This equipment adopts boiling semi gasification combustion and tangential swirl air distribution design, which enables complete combustion of fuel with a combustion efficiency of over 90%.

Lane can customize a burner for you to meet any of your needs.

Burner |

|||

|---|---|---|---|

| Model | Heat quantity(wkcal) | Porwer(kw) | Unit energy consumption(kg/h) |

| LA-30F | 30 | 1.3 | 70 |

| LA-60F | 60 | 1.9 | 150 |

| LA-90F | 90 | 2.3 | 230 |

| LA-120F | 120 | 2.8 | 300 |

| LA-180F | 180 | 3 | 450 |

| LA-240F | 240 | 3.8 | 600 |

| LA-300F | 300 | 5.3 | 750 |

| LA-360F | 360 | 6 | 900 |

| LA-480F | 480 | 9.3 | 1200 |

| LA-600F | 600 | 16.5 | 1500 |

| LA-900F | 900 | 23.5 | 2250 |

Through the feeding device, the raw materials enter the storage bin, the air is sent into the furnace, the high temperature cracking suspension semi-gasification combustion, and then the output heat transfer to the energy use equipment. Using the principle of radiant heat and convective heat, the sawdust is fully burned in the furnace of the combustion machine with three times of air oxygenation, and more than 98% of the heat is transferred to the energy using equipment.

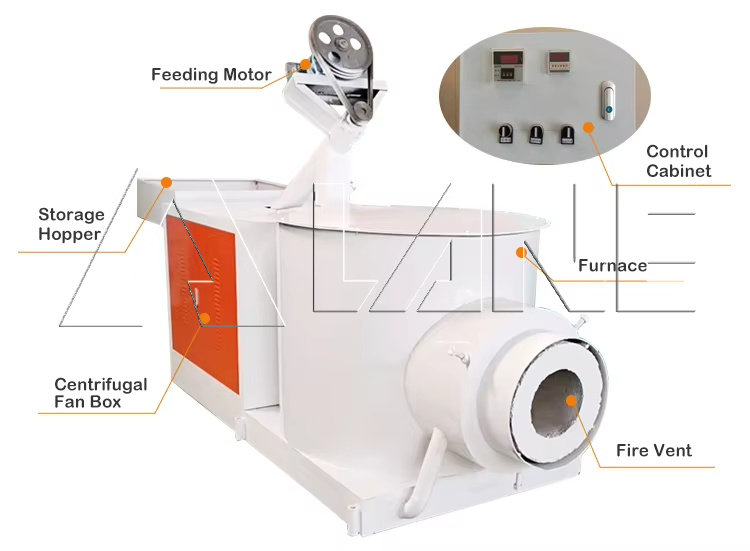

It mainly consists of the following parts:

1. Air intake system

The intake system of the burner introduces external air into the burner through pipes and thoroughly mixes fuel and air. The intake system mainly consists of an inner pipe, an outer pipe, an air guide plate, a regulator, a nozzle, etc.

2. Combustion chamber

A combustion chamber is a place where high-temperature and high-pressure gases are produced through the chemical reaction between fuel and air. The combustion chamber is divided into two types: direct combustion and indirect combustion. A direct combustion chamber burns directly after mixing fuel and air, producing high-temperature and high-pressure gas directly. Indirect combustion chambers first oxidize the fuel nearby, then mix it with air and burn it, producing high-temperature and high-pressure gas.

3. Combustion head

The combustion head is a place where fuel and air mix. After the fuel comes out of the nozzle, it mixes with the air entering the combustion head to form combustible gas, which is ignited by the igniter and produces high-temperature and high-pressure gas in the combustion chamber.

4. Control system

The control system of the burner includes ignition control, temperature control, and pressure control. Through the control system, the burner can maintain a stable combustion state, ensure the quality of the outlet gas, and also achieve high efficiency and energy conservation.

For more information, please contact us by sending an inquiry today! We can help you!

Low cost

Using wood chips as fuel, it has high firepower value, stable flame, no smoke, no tar, and clean combustion with less ash powder.

Easy to operate

The device has a simple structure, wide applications, easy operation, and convenient daily maintenance.

Stable performance

The product has stable performance, low energy consumption, high efficiency, and effectively improves usage time.

World-class and Energy-saving Operation, Factory Price & Fast Delivery.