In the entire pellet production line, the role of the ring die pellet machine is the key equipment to process raw materials such as wood chips, branches, sawdust, logs, crop straw, etc. into pellets. The production capacity of the ring die biomass pellet machine ranges from 500kg/h to 3 tons/h, which can be used for both small-scale and large-scale pellet production.

Ring die pellet machines are mainly divided into two types – vertical ring die pellet machines and horizontal ring die pellet machines. They all have their own characteristics.

There are many differences between the vertical ring die pellet machine and the horizontal ring die pellet machine, but the biggest difference between the two ring die pellet machines is the working principle.

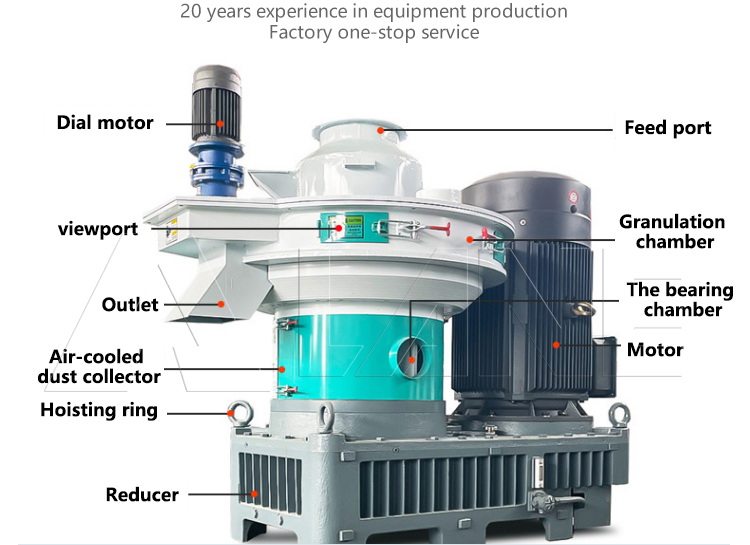

The vertical ring die pellet machine is specially designed for difficult-to-form materials. The material can enter the pelletizing chamber by its own weight, and enter the die hole to form pellets under the strong pressure between the rotating roller and the ring die. Vertical ring die pellet mill is also called light material pellet mill, because vertical pellet mill is more suitable for processing light weight materials, such as rice husk, light weight grass, straw, melon and fruit shells and materials that are not easy to shape.

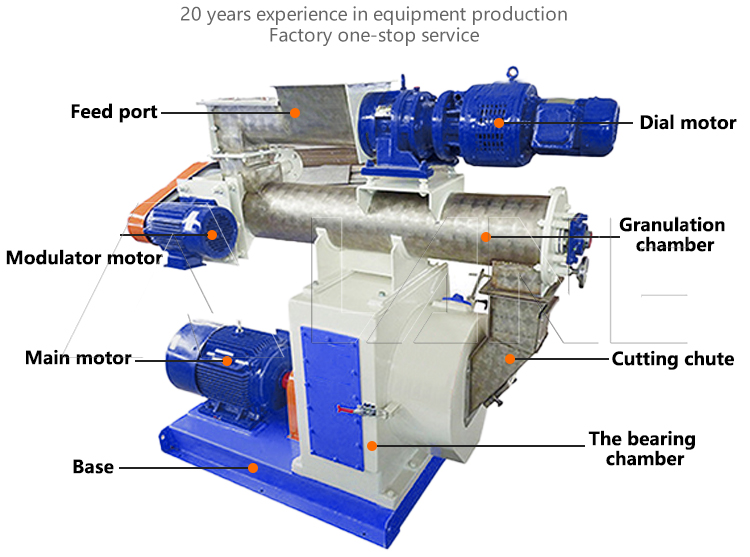

Unlike vertical ring die pellet mill, horizontal ring die pellet mill uses feeding auger to send materials into pelletizing chamber through silo. The materials begin to soften in the closed pelletizing chamber. Under the huge squeeze between high-speed rotating ring die and roller, the soft materials are pressed into the evenly distributed holes on the die head, and then the cylindrical solid body formed outside the hole is cut off by the cutter and discharged through the outlet.

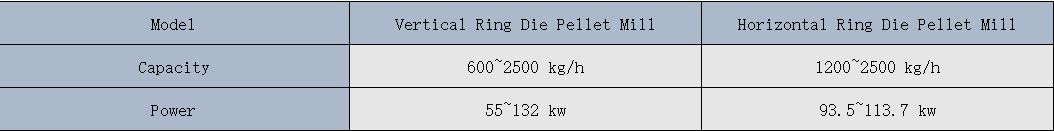

Here are only the basic parameters of two types of ring die pellet mills. For more detailed technical data and price list, please contact us directly, we can send a free quotation quickly!

The vertical ring die pellet machine is open from top to bottom. The raw materials enter the pelletizing die directly from top to bottom. During the falling process, they are thrown to the surrounding pressure rollers to rotate, and then are evenly pressed and formed. Since the mold is flat, the raw materials will not accumulate at the bottom of the mold, which greatly reduces the risk of blockage.

The ring die of the vertical ring die pellet machine is a roller rotation, and the mold does not move, so the pellets will not be hit twice, so the pelletizing rate is higher than that of the horizontal ring die pellet machine. Due to its structural characteristics, its heat dissipation efficiency is also very good, which prolongs the working time.

The horizontal ring die pellet machine has a simple structure, wide adaptability, small footprint and low noise. It is mainly used for animal feed, with large output, suitable for small and medium-sized enterprises. The ring die of the horizontal ring die pellet machine is a mold rotation, and the auxiliary roller is driven to rotate. During high-speed rotation, the pellets rotate with the mold. The granulation chamber of the horizontal ring die pellet machine is sealed to prevent dust leakage.

Henan Lane Heavy Industry Machinery Technology Co., Ltd., Zhengzhou, has been providing customized process and production line solutions for equipment manufacturing for the fertilizer industry for more than 20 years, including organic fertilizer production lines with an annual output of 1,000-200,000 tons, compound fertilizer production lines with an annual output of 1,000-300,000 tons, water-soluble fertilizer production lines with an annual output of 1,000-2—– tons, and liquid fertilizer production lines. We can not only provide you with production line solutions, but also solve other production problems for you.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales2@lanesvc.com

Tel: +86 15515885328

Whatsapp: +86 15515885328