Brand: LANE

Production line advantages:

High production efficiency, 1-5 tons per hour

Applicable materials:

Chicken manure, cow manure, sheep manure, pig manure and other animal manure and carbon-containing materials such as plants

Warranty: 5 Years

Delivery Time: Within 45 days

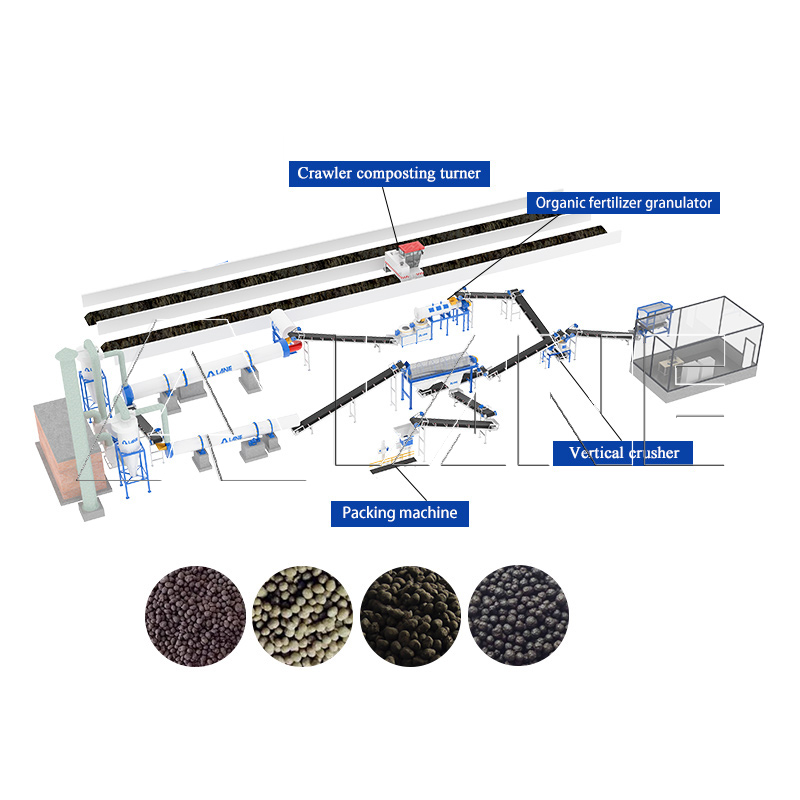

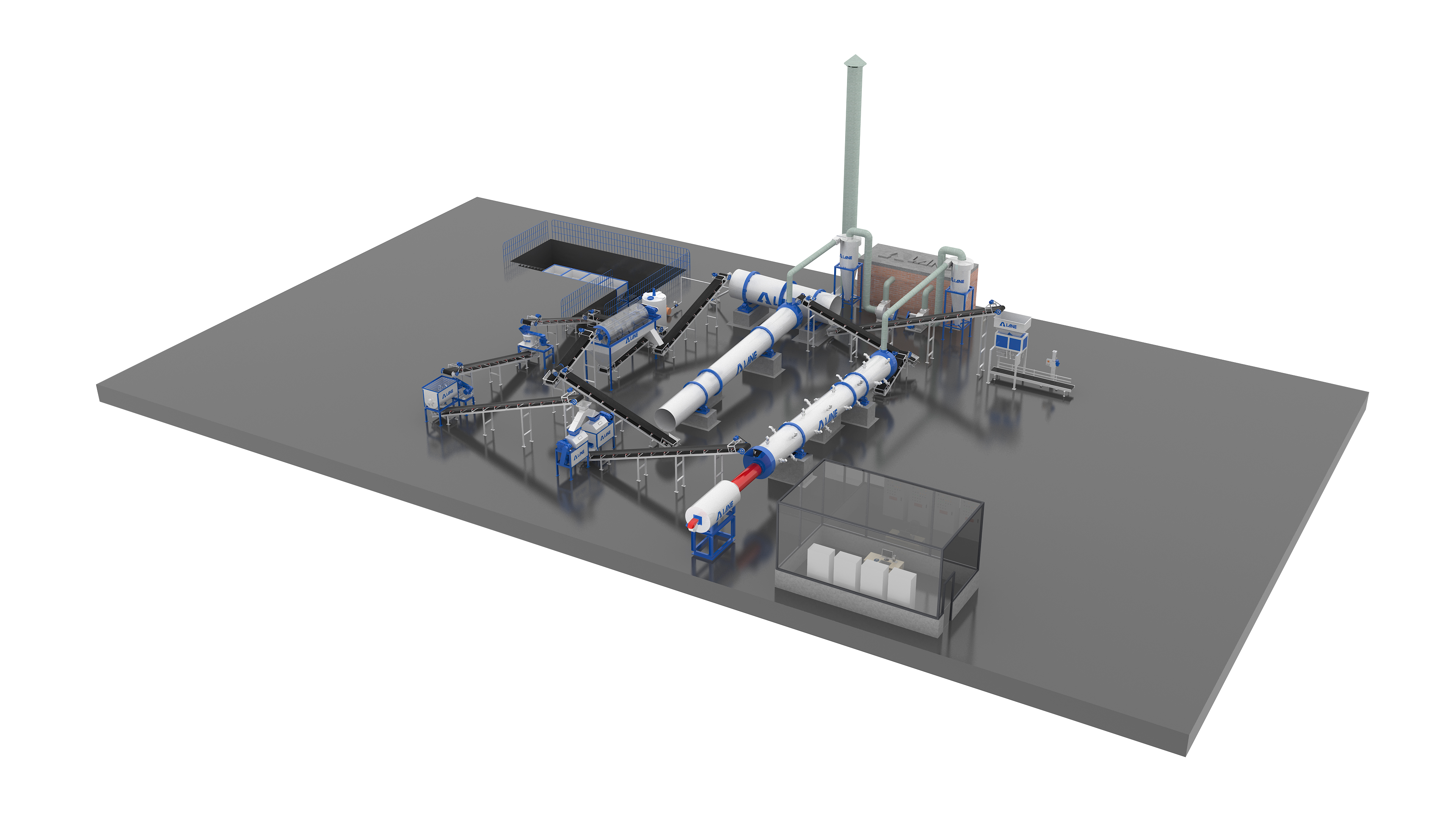

The chicken manure fertilizer production line is a complete production system that uses fresh chicken manure as raw material, processes it through a series of processing procedures, and ultimately produces natural organic chicken manure fertilizer. The process of chicken manure fertilizer production line is divided into two main steps: initial fermentation and pretreatment stage, and deep processing granulation stage. In order to complete these steps, bio organic fertilizer production equipment needs to include fermentation turntables, organic fertilizer crushers, drum screening machines, horizontal mixers, disc granulators, rotary dryers, coolers, screening machines, coating machines, packaging machines, and conveyors.

You can click on the numbers to see detailed pictures!

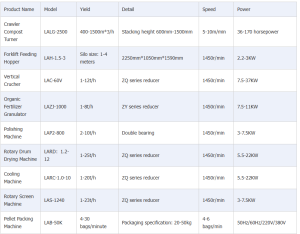

The following are the product parameters used in the Chicken manure fertilizer production line:

1. Crush and mix the raw materials

Use the batching bin to crush, batch and mix the composted materials, inorganic fertilizers such as N, P, K and other additives in a certain proportion through the material crusher and horizontal mixer. According to years of experience, a vertical crusher can be used, which is not easy to stick to the wall and not easy to clog, and improves the crushing performance.

2. Organic fertilizer granulation

Mix the crushed ingredients and make them into granules. Granulation uses a new type of organic fertilizer granulator, which has wide requirements for raw material density and raw material moisture, and the raw materials do not need to be dried; the granule formation rate is high, the finished granules have a uniform appearance and are not easy to break.

3. Screening and material return system

The granules output from the granulation molding system have certain differences in particle size and need to be screened and graded. A rotary screening machine can be selected, which has low vibration, low noise, convenient net change, and is equipped with a screen surface cleaning device.

4. Finished product system

4.1 Drying: Use an organic fertilizer dryer to further remove moisture from the screened particles to meet the standard requirements for organic fertilizer moisture content.

4.2 Cooling: Cooling the granular materials with a cooler is beneficial to the storage and quality assurance of the granules. The hot granular materials output from the dryer enter the cooler. After cooling, the difference between the granular temperature and the ambient temperature is less than 5°C.

4.3 Packaging: The cooled granular materials are transported to the finished product warehouse through a bucket elevator, and the granular materials are quantitatively weighed and packaged by an automatic packaging scale.

The above process stages and fermentation methods are used to realize the harmless disposal of chicken manure, so as to make environmentally friendly, nutrient-rich, and up-to-standard chicken manure organic fertilizer.

For more information about the chicken manure fertilizer production line, please contact us by sending an inquiry today! We can help you!

Chicken manure fertilizer production line

Finished product samples: