The chicken manure organic fertilizer granulation process is one of the most practical ways to turn poultry waste into valuable fertilizer. With the rapid growth of poultry farming, large amounts of chicken manure are produced every day. If not handled properly, it can cause odor, pollution, and resource waste. By using a complete fertilizer production line, chicken manure can be converted into uniform, easy-to-use fertilizer granules that are suitable for modern agriculture.

This article introduces the chicken manure organic fertilizer granulation process from the perspective of production equipment. We focus on machine performance, working principles, and practical operation, using clear language and simple explanations to help readers understand the full process.

Chicken manure is rich in nitrogen, phosphorus, potassium, and organic matter. Compared with other animal manure, it has higher nutrient content and faster fertilizer efficiency. However, fresh chicken manure has high moisture and strong odor, so it cannot be applied directly to crops.

This is where the chicken manure organic fertilizer granulation process becomes important. Through fermentation, crushing, mixing, and granulation, raw manure is transformed into stable, odor-free, and easy-to-store fertilizer granules.

The complete chicken manure organic fertilizer granulation process usually includes the following steps:

Each step relies on specific equipment designed to improve efficiency and product quality.

Fresh chicken manure often contains impurities such as stones, feathers, and plastic. A simple screening machine is used to remove these materials. The equipment structure is straightforward, using a rotating or vibrating screen to separate unwanted objects.

Good pre-treatment ensures smooth operation in the later stages of the chicken manure organic fertilizer granulation process and protects downstream machines from damage.

Fermentation is the core step in organic fertilizer production. During this stage, harmful bacteria are killed, and organic matter is decomposed.

Common fermentation equipment includes:

Groove type compost turners

Crawler type compost turners

These machines work by regularly turning the manure pile, allowing oxygen to enter and heat to spread evenly. The turning system usually uses a rotating blade shaft powered by a motor. This improves fermentation speed and shortens processing time in the chicken manure organic fertilizer granulation process.

After fermentation, the material may form clumps. A crusher is used to break these into fine particles. Vertical crushers and chain crushers are widely used due to their simple structure and stable performance.

The crushing machine works through high-speed rotating blades that impact and shear the material. Uniform particle size is essential for smooth granulation in the next stage of the chicken manure organic fertilizer granulation process.

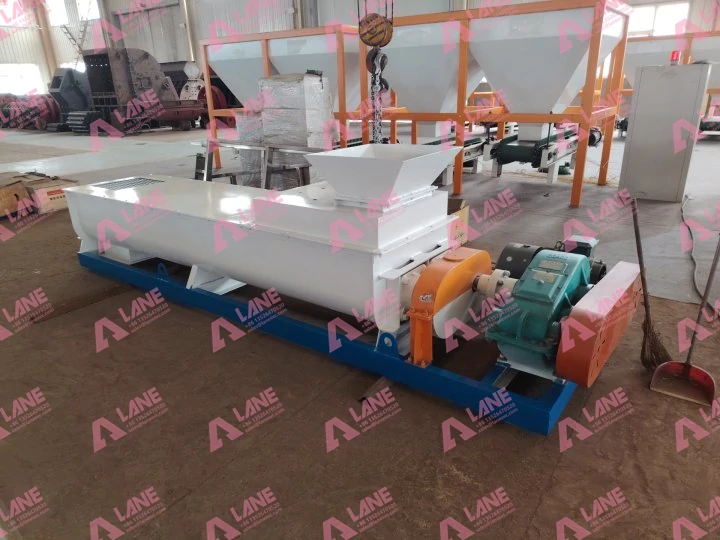

Mixing equipment ensures that chicken manure powder and additives are evenly blended. Horizontal mixers and double-shaft mixers are commonly used.

The mixer works by rotating paddles that move materials in multiple directions. This simple mechanical action ensures consistent fertilizer quality, which is a key requirement in the chicken manure organic fertilizer granulation process.

Granulation is the step that gives fertilizer its final shape. Common machines include disc granulators, drum granulators, and stirring pin granulators.

These machines rely on rotation and friction. When powder material enters the granulator, it rolls continuously and forms round granules under controlled moisture and pressure. The granulator’s stable operation directly affects granule size, strength, and appearance in the chicken manure organic fertilizer granulation process.

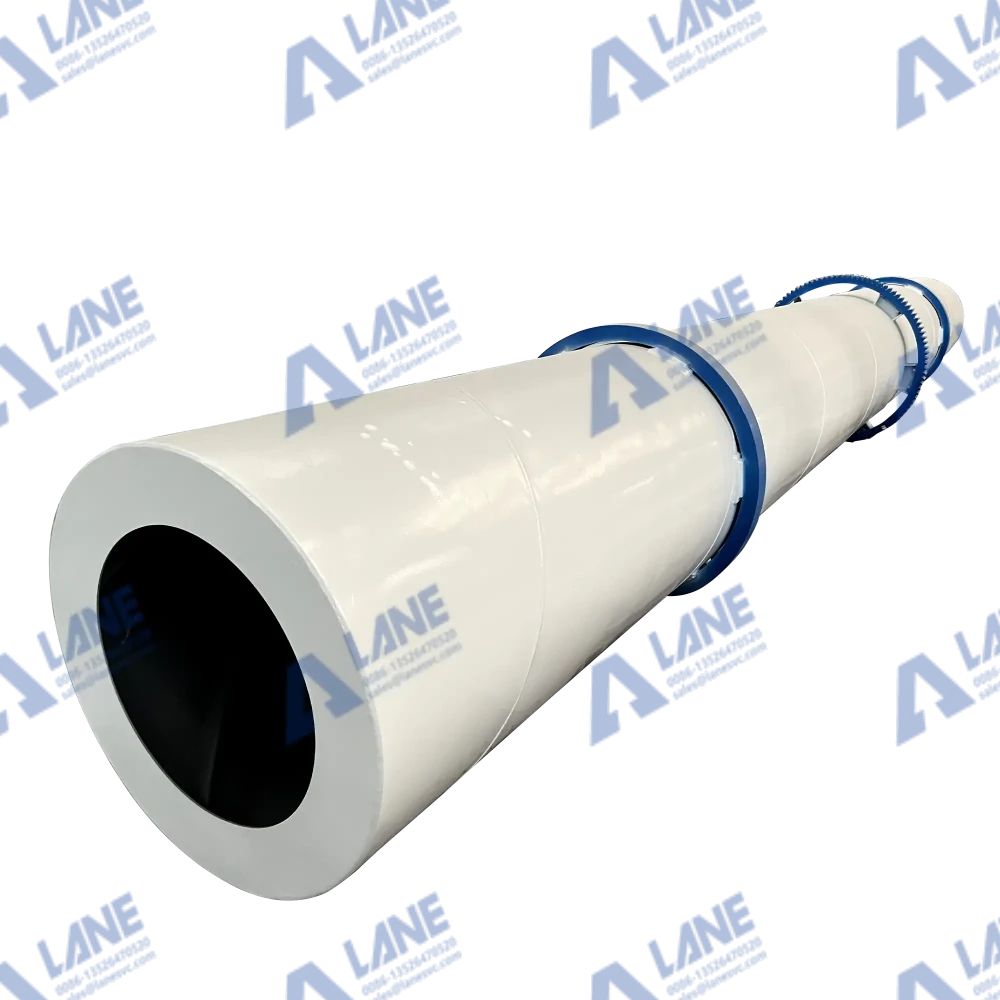

Fresh fertilizer granules contain moisture and must be dried for storage and transportation. Rotary dryers are widely used due to their high efficiency and simple operation.

The dryer works by rotating a drum while hot air flows through it. After drying, a cooling machine reduces granule temperature, preventing caking. These machines ensure product stability in the final stage of the chicken manure organic fertilizer granulation process.

Screening machines separate qualified granules from oversized or undersized ones. Qualified products go directly to packaging machines.

Automatic packaging machines use weighing systems and conveyor belts to fill bags efficiently. This final step completes the chicken manure organic fertilizer granulation process and prepares the product for the market.

The equipment used in the chicken manure organic fertilizer granulation process is designed for:

Simple mechanical structures reduce downtime and make daily operation easier, even for beginners.

At LANE, our company has been focusing on fertilizer machinery manufacturing in China for over 20 years. We have an experienced engineering team, and we design complete organic fertilizer production lines based on customer needs. In the chicken manure organic fertilizer granulation process, we provide reliable equipment, clear layouts, and smooth installation support.

We follow ISO9001 and CE quality standards, and we support our customers with installation guidance and after-sales service. For us, stable equipment performance and easy operation are always the priority.

Suitable Applications and Production Scales

The chicken manure organic fertilizer granulation process is suitable for:

Production capacity can be adjusted by selecting different equipment models, making the process flexible for different investment levels.

The chicken manure organic fertilizer granulation process is an efficient and practical solution for turning poultry waste into high-value fertilizer. By using well-designed equipment with simple working principles, producers can achieve stable output, good granule quality, and long-term operation.

Understanding how each machine works helps users make better decisions and ensures smooth production. With the right equipment and proper process design, chicken manure can become a reliable resource for sustainable agriculture.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520