Introduction: From Waste to Resource

Continuous development of the breeding and poultry industry has given rise to many chicken farms. This presents a familiar challenge: a constant stream of waste that can be an environmental liability if mismanaged. However, chicken manure is a high-quality raw material for organic fertilizers. It contains rich nutrients such as nitrogen, phosphorus, and potassium. With the right approach and technology, it can be transformed into a marketable organic fertilizer. A small-scale chicken manure organic fertilizer production line can be the key to this transformation.

For small and medium-size farms and investors, a chicken manure organic fertilizer production line turns a disposal problem into a profitable and sustainable venture.

This guide will walk you through the process, with a focus on reliable machinery solutions from LANE Heavy Industry. LANE Heavy Industry, a professional manufacturer of organic fertilizer production machinery, provides customized solutions for small-scale production.

Why Invest in a Small-Scale Production Line?

A dedicated production line is different from traditional passive composting. It offers controlled, efficient, and scalable production with these benefits:

- Profit Center: It creates a new revenue stream.

- Cost Savings: It eliminates disposal fees and reduces reliance on commercial fertilizers for your own land.

- Environmental Compliance: It provides an eco-friendly manure management solution; this reduces runoff and odor issues.

- Soil Health: A chicken manure organic fertilizer production line produces superior organic fertilizer that improves soil structure, water retention, and microbial life.

- Market Demand: It meets the growing global demand for organic agricultural inputs.

The Core Process: How the Production Line Works

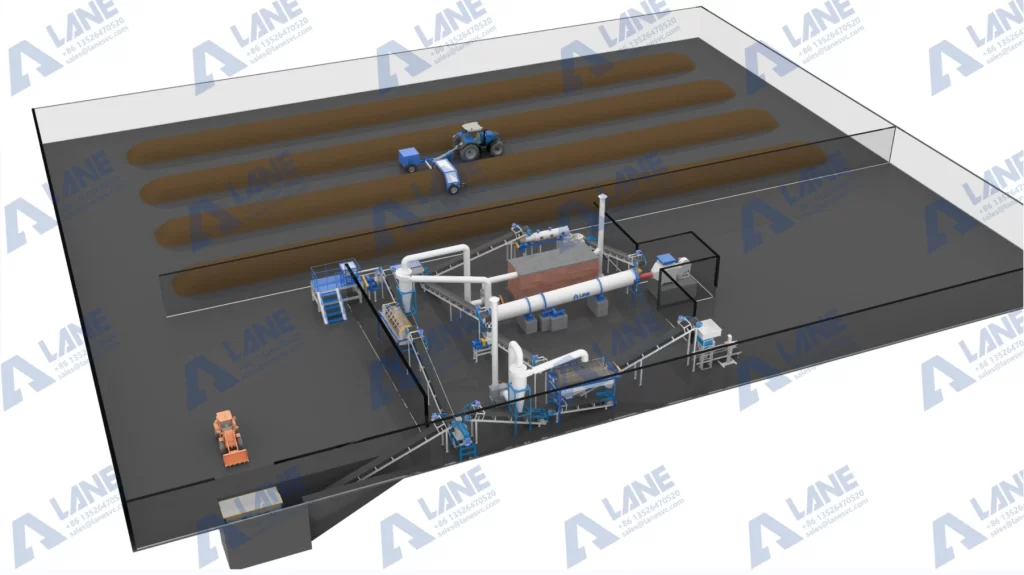

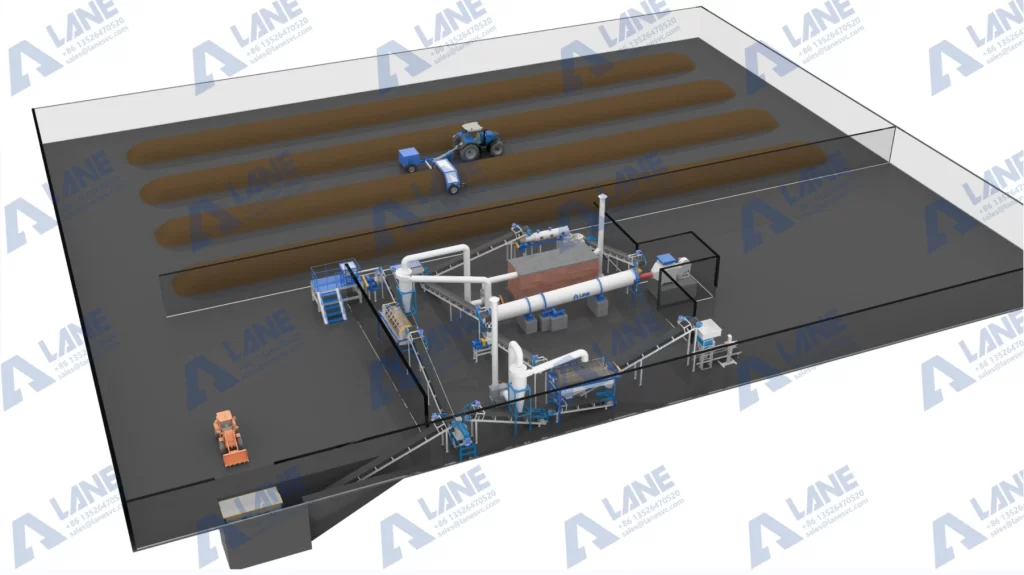

A complete chicken manure organic fertilizer production line creates fertilizer through several stages.

- Fermentation & Drying:Fresh manure is mixed with other raw materials and placed in a fermentation tank or windrow to break down pathogens and weed seeds.

- Crushing & Mixing:After fermentation and curing, the composted materials are sent to a crusher. It is crushed to a fine powder and blended uniformly to ensure consistent nutrient content.

- Granulation:The fine powder is formed into durable, easy-to-handle pellets using a granulator. Granulation increases the value of the organic fertilizer.

- Drying & Cooling:The wet granules are dried to achieve ideal moisture content and then cooled to solidify the granules and prepare them for the screening stage.

- Screening & Packaging:Finished granules are screened to separate out fine and irregularly sized pellets. They are sent back to the crusher to be recycled. The on-size product is bagged for storage or sale.

LANE Heavy Industry provides a selection of core machines that are essential for efficient production of organic fertilizer. LANE engineers can create a custom, scalable design ideal for small to mid-scale operations.

- Crawler-Type Compost Turner: This is critical for the fermentation phase in the Chicken Manure Organic Fertilizer Production Line. LANE’s turner efficiently aerates and mixes the windrows, speeds up decomposition, and kills weed seeds and pathogens.

- Vertical Crusher: This crusher powerfully pulverizes the fermented clumps into a fine powder. This step is critical for uniform granulation size.

- Horizontal Mixer: LANE’s horizontal mixer blends powdered manure with other additives. You can create a custom formulation with the help of this mixer.

- Stirring Pin Granulator: This is the heart of the granulation stage. LANE’s Stirring Pin Granulators have a 97% granulation rate. They form dense, high-density granules from the mixed powder.

- Rotary Drum Dryer & Cooler: LANE’s rotary drum drying and cooling system removes excess moisture from the pellets and stabilizes them for storage.

- Rotary Screening Machine: It separates finished, on-spec granules from the fine powder and broken pieces. This ensures a polished final product.

Step-by-Step Guide to Setting Up Your Line

- Feasibility & Planning: You must assess your daily manure output, available space, budget, and local market for organic fertilizer.

- Site Preparation:Choose a well-drained, accessible area. Prepare separate spaces for raw material, the fermentation area, the factory area, and finished product storage.

- Machinery Selection & Acquisition:Consult with LANE Heavy Industry to select the right configuration for your chicken manure organic fertilizer production line.

- Installation & Commissioning:LANE typically provides layout drawings and installation guidance. Ensure that electrical and foundation work is done before installing the equipment.

- Staff Training & Trial Run:Train your technicians on safety and procedures with the help of LANE. Do a trial batch to calibrate the machines and refine the process.

Best Practices for Operation and Success

- Pre-treatment is Key: In the Chicken Manure Organic Fertilizer Production Line, the first step is to properly dewater the fresh manure and maintain the right carbon-to-nitrogen ratio during fermentation to ensure efficient composting.

- Routine Maintenance: Follow a strict schedule for greasing, inspection, and part replacement to avoid costly downtime.

- Quality Control: Regularly test your raw manure and finished fertilizer for nutrient content and moisture levels.

- Start Local: Build your initial market with neighboring organic farms, nurseries, and garden centers.

Conclusion: A Sustainable Investment

Setting up a small-scale chicken manure organic fertilizer production line is an important way to realize the resource utilization of chicken manure and develop a circular economy. By partnering with a reliable equipment provider like LANE Heavy Industry, you gain access to the tailored machinery and technical support needed to build a successful, sustainable operation. LANE Heavy Industry’s chicken manure organic fertilizer production line provides strong support for investors and farmers to carry out organic fertilizer production business.

Frequently Asked Questions (FAQ)

Q1: What is the total investment cost for a small-scale line?

A1: For a basic line with a capacity of 1-2 tons per hour, the investment in LANE Heavy Industry machinery can range from $50,000 to $100,000, depending on the level of automation and ancillary equipment (like packaging systems). Site preparation and installation are additional costs.

Q2: How much space do I need?

A2: A minimum area of 500 square meters is recommended. This should accommodate a fermentation shed (approx. 300-400 sqm), a machinery installation area, and space for raw materials and finished product storage.

Q3: Is the process very technical to operate?

A3: The core process is straightforward. LANE Heavy Industry provides operational manuals and training. Key skills involve monitoring fermentation parameters, operating the machinery controls, and performing basic maintenance.

Q4: What is the profit potential?

A4: Profitability depends on your input costs, scale, and local fertilizer prices. Processed organic fertilizer typically sells for a significant premium over raw manure. Many operations see a return on investment within 2-3 years through direct sales and internal cost savings on fertilizer and waste management.

Q5: Can LANE Heavy Industry provide a customized solution?

A5: Yes. LANE Heavy Industry specializes in assessing client needs and tailoring the chicken manure organic fertilizer production line configuration, from individual machines to complete turnkey plants, to match specific output goals, raw material characteristics, and budget constraints.

For more details, please feel free to contact us.