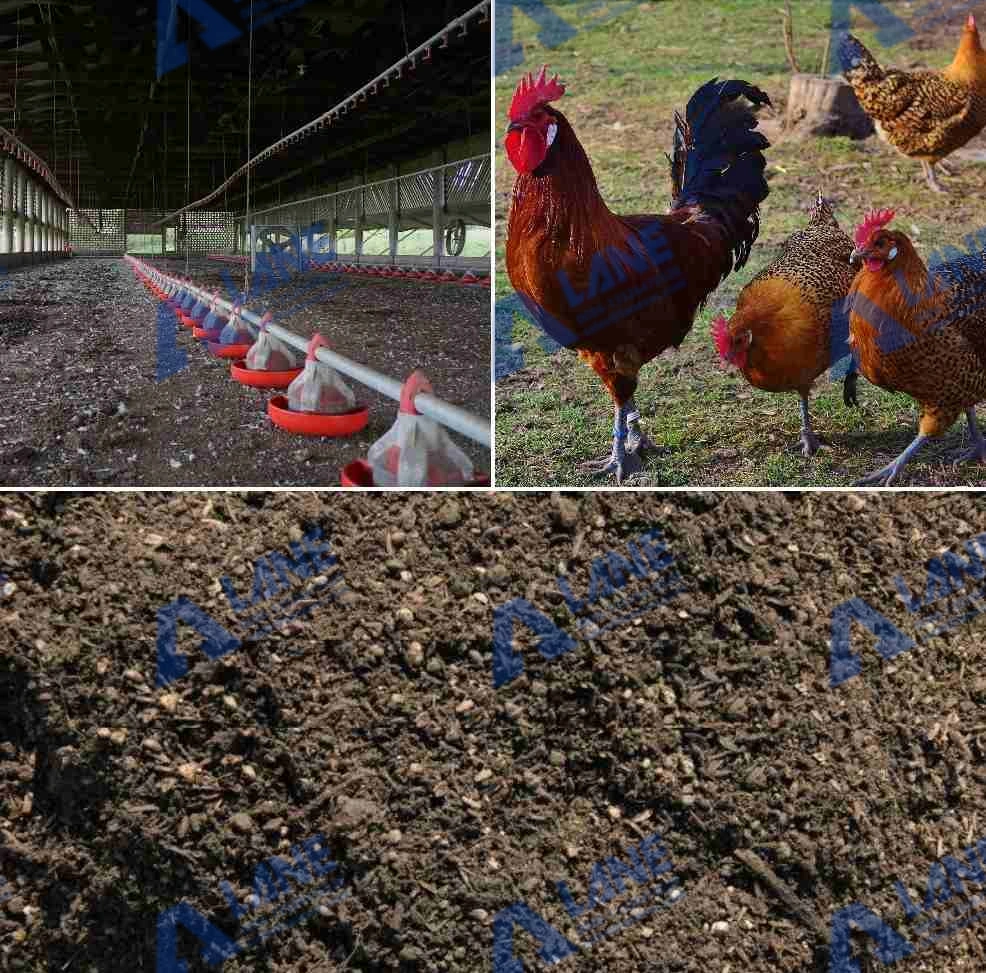

Poultry farming is one of the fastest-growing agricultural industries worldwide. Along with its rapid development, the production of chicken manure has also increased rapidly. Every year, millions of tons of poultry manure are produced, posing a serious challenge to the environment. Unprocessed manure piles up in mountains, causing water pollution, unpleasant odors and greenhouse gas emissions. However, this problem can be transformed into a valuable opportunity.

The solution lies in the chicken manure organic fertilizer production line. With the right technology, chicken manure becomes a powerful organic fertilizer rich in nitrogen, phosphorus, and potassium. Instead of being an environmental burden, it can improve soil fertility, boost crop yields, and generate additional income for farmers.

Why Focus on Chicken Manure Organic Fertilizer Production Line?

Chicken manure stands out among animal wastes because it contains higher levels of nutrients. On average, fresh chicken manure contains around 1.6% nitrogen, 1.5% phosphorus, and 0.9% potassium—figures that make it one of the best raw materials for organic fertilizer.

However, untreated chicken manure also carries pathogens, unpleasant smells, and high levels of ammonia. Direct application to the field is not recommended. The chicken manure organic fertilizer production line solves this by safely composting and processing the manure into stable, marketable products.

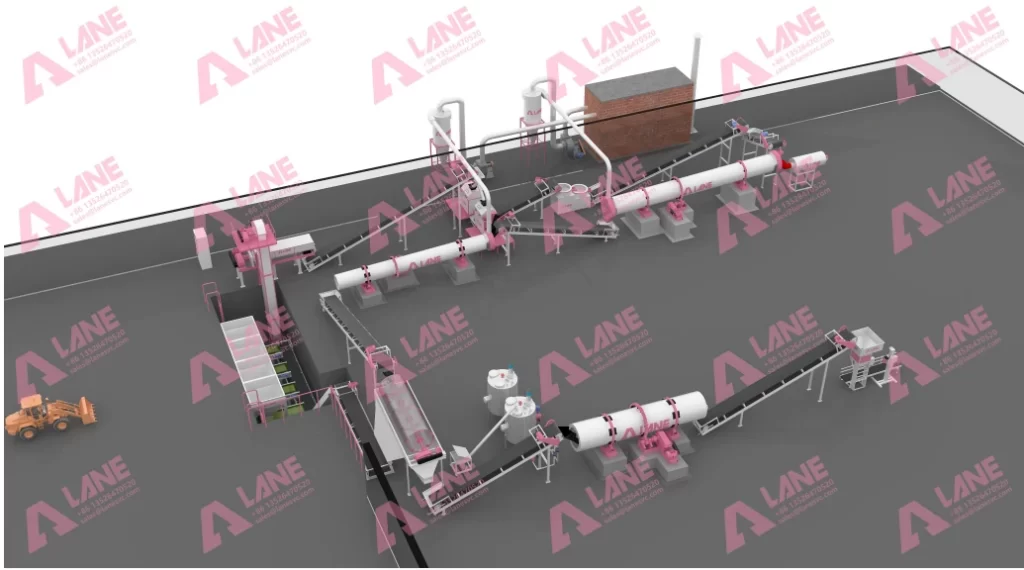

Step-by-Step Process of a Chicken Manure Organic Fertilizer Production Line

Building a chicken manure organic fertilizer production line involves several coordinated steps. Each stage has its own function and relies on specialized equipment to ensure efficiency and product quality.

Step 1: Collection and Pre-Treatment

The process begins with the collection of fresh chicken manure from poultry houses. Typically, the manure contains 70–80% moisture, making it too wet for direct composting. To address this, it is first sent through an inclined dewatering machine, which reduces the moisture content to around 60–65%, the ideal range for fermentation. At this stage, crop residues like rice husks or straw can be added to balance carbon-to-nitrogen ratios (C/N ratio of 25–30 is ideal). Pre-treatment not only optimizes composting conditions but also reduces odor during the next stage.

Step 2: Composting and Fermentation

The dewatered manure is piled into windrows or placed inside vertical fermentation tank. During fermentation, microbial activity generates heat, raising temperatures to 55–65°C. This thermophilic stage is critical for pathogen destruction and odor reduction. A crawler type compost turner or groove-type turner mixes the pile every 2–3 days to ensure proper aeration and prevent anaerobic zones. Farmers may also inoculate the pile with beneficial microorganisms (e.g., Bacillus or actinomycetes) to accelerate decomposition and improve nutrient availability. Composting usually lasts 20–25 days, but with optimized management, the cycle can be shortened to about 15 days.

Step 3: Crushing

After fermentation, the compost becomes stable but often contains clumps due to moisture variation. To ensure uniform particle size, the material is processed through a vertical shaft crusher. This step breaks down lumps and produces a fine texture, making the fertilizer easier to handle and apply. Crushing also increases the surface area of particles, enhancing nutrient release once applied to soil.

Step 4: Screening

Screening is carried out using a rotary screener, which separates qualified compost powder from oversized particles or unfermented residues. The undersized materials move forward to the next step, while oversized particles are returned to the crusher for reprocessing. This step ensures product consistency, which is crucial for market acceptance and application efficiency.

Step 5: Mixing with Additives

At this stage, the compost can be left as-is or enriched with additional nutrients. A horizontal mixer is used to blend the material with additives like humic acid, biochar, or trace minerals such as zinc and boron. In some advanced setups, microbial inoculants (e.g., nitrogen-fixing bacteria) are added to enhance soil health benefits. Mixing ensures uniform distribution of additives and creates value-added fertilizer formulations tailored to specific crops or soils.

Step 6: Packaging

Finally, the processed fertilizer is packaged. An automatic packaging machine accurately measures and seals the powder in moisture-proof bags, usually ranging from 25 kg to 50 kg. Proper packaging prevents moisture absorption and extends shelf life. Some production lines also include palletizing systems to improve logistics and distribution efficiency.

Optional Step: Granulation Upgrade

Although the primary product is powder, many facilities later expand into granule production. By adding equipment such as a stirring pin granulator, rotary drum dryer, and rotary cooler, the same compost can be turned into granular fertilizers. Granules are easier to transport, store, and spread, providing an additional revenue stream for producers.

Advantages of a Chicken Manure Organic Fertilizer Production Line

The system provides benefits on multiple levels:

Environmental Protection: Prevents pollution from untreated poultry waste and reduces greenhouse gas emissions.

Nutrient Recycling: Converts waste into fertilizers that improve soil fertility and structure.

Cost Reduction: Farmers save on chemical fertilizer purchases.

Market Opportunities: Processed chicken manure fertilizers can be sold locally or exported.

Sustainability: Supports circular agriculture, where waste becomes a resource.

Unlike chemical fertilizers, chicken manure compost also boosts microbial diversity in the soil, leading to long-term agricultural resilience.

Case Example 1: Poultry Cooperative in Thailand

In northern Thailand, a poultry farming cooperative struggled with waste disposal. Farmers faced complaints from surrounding communities due to odor and flies. By investing in a chicken manure organic fertilizer production line, they transformed thousands of tons of waste into organic fertilizers each year.

The fertilizers were used in nearby rice paddies and vegetable farms, improving crop health and reducing reliance on chemical inputs. Local farmers even reported better taste and shelf life in their produce. What began as a waste management project soon turned into a profitable business model for the cooperative.

Case Example 2: Family Farm in Brazil

A medium-sized poultry farm in southern Brazil installed a small-scale chicken manure organic fertilizer production line. Instead of selling raw manure at very low prices, the farm processed it into high-quality organic fertilizers.

Local vegetable growers and coffee plantations quickly became regular buyers. Within two years, the farm not only eliminated its waste disposal problems but also developed a new revenue stream. The story illustrates how even family-owned farms can benefit from adopting advanced fertilizer production technology.

Applications in Agriculture

Rice and Wheat Cultivation: Provides slow-release nutrients that support high yields.

Vegetables: Enhances flavor, texture, and shelf life.

Fruit Orchards: Improves flowering, fruit set, and soil health.

Greenhouses: Compatible with organic farming systems and sustainable practices.

Challenges and Practical Solutions

While the technology is effective, it comes with challenges. One major issue is the high moisture content of fresh manure, which slows down composting. This is solved by pre-treatment with dewatering equipment and balancing moisture with crop residues like rice straw.

Another challenge is odor control. During composting, unpleasant smells may develop if aeration is insufficient. Regular turning with compost machines and microbial inoculants help reduce odors significantly.

Finally, many farmers worry about investment costs. Cooperative models, government subsidies, and gradual scaling of the chicken manure organic fertilizer production line make the system more affordable and accessible.

Economic Value and Business Opportunities

The adoption of a chicken manure organic fertilizer production line creates strong economic value for both smallholders and large-scale poultry operations. Instead of treating manure as a waste product with disposal costs, farms can process it into fertilizers that sell at competitive prices in local and regional markets.

The business opportunities extend beyond farms themselves. Cooperatives, private entrepreneurs, and agricultural service companies can establish centralized production lines and sell fertilizers to nearby growers. In regions with growing organic food demand, processed chicken manure fertilizer has strong potential to command premium prices. Export markets also provide additional opportunities, particularly in areas where organic certification is highly valued.

This means that what was once a liability—poultry waste—can be transformed into a consistent source of revenue. The chicken manure organic fertilizer production line therefore not only supports sustainability but also strengthens rural economies.

Innovation and Technological Trends

The future development of the chicken manure organic fertilizer production line is closely linked with agricultural innovation. New composting methods are being designed to accelerate fermentation, reduce odor, and improve nutrient retention. Equipment such as automated compost turners, intelligent mixing systems, and energy-efficient dryers are becoming more accessible, even for medium-sized farms.

Another trend is the integration of digital agriculture. Sensors, IoT platforms, and AI-driven monitoring tools are being introduced to track moisture, temperature, and nutrient levels in real time. These technologies ensure consistent product quality while lowering labor requirements.

Sustainability goals are also driving innovation. Renewable energy integration—such as solar-powered mixers or biogas recovery from manure—will make production lines even more eco-friendly. These advancements will shape the future of the industry, ensuring that the chicken manure organic fertilizer production line remains a cornerstone of sustainable poultry farming and soil improvement worldwide.

The chicken manure organic fertilizer production line is more than just a waste management solution. It is a transformative system that turns poultry waste into agricultural wealth. By enhancing soil fertility, supporting sustainable farming, and creating new market opportunities, it benefits both farmers and the environment.

From Thai cooperatives to Brazilian family farms, success stories prove that this technology adapts to different scales and contexts. As innovation continues and markets grow, the chicken manure organic fertilizer production line will remain essential in building a greener, more resilient, and profitable agricultural future.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520