Bio-organic fertilizer production from agricultural waste is no longer a futuristic idea; it has become a cornerstone of sustainable farming. Every year, farms around the world generate millions of tons of crop residues, rice husks, manure and other organic by-products. Nowadays, advanced production systems no longer allow these biomass to rot or be burned, but convert them into high-quality bio-organic fertilizers, which not only nourish crops but also alleviate environmental pressure.

For decades, LANE has accumulated experience in the construction of integrated fertilizer plants, demonstrating how to transform agricultural waste into reliable resources through carefully designed processes, equipment and easy-to-operate solutions.

Why Agricultural Waste is the Perfect Feedstock

Agricultural waste offers an abundant, renewable, and nutrient-rich source for bio-organic fertilizer production. Unlike chemical fertilizers, which often focus on NPK values alone, waste-derived fertilizers contribute additional organic matter and beneficial microbes that enrich the soil.

| Type of Agricultural Waste | Fertilizer Value | Example Nutrients |

| Crop residues (straw, husks, stalks) | High in carbon for compost balance | Cellulose, lignin |

| Animal manure (poultry, cattle, sheep) | Nitrogen-rich and microbe-friendly | Nitrogen, phosphorus |

| Fruit and vegetable waste | Fast-decomposing organic material | Potassium, micronutrients |

| Agro-industrial by-products | Adds specialized nutrients | Bagasse, press mud |

The diversity of agricultural waste ensures flexibility in plant design. LANE tailors production lines based on raw material availability, guaranteeing maximum efficiency.

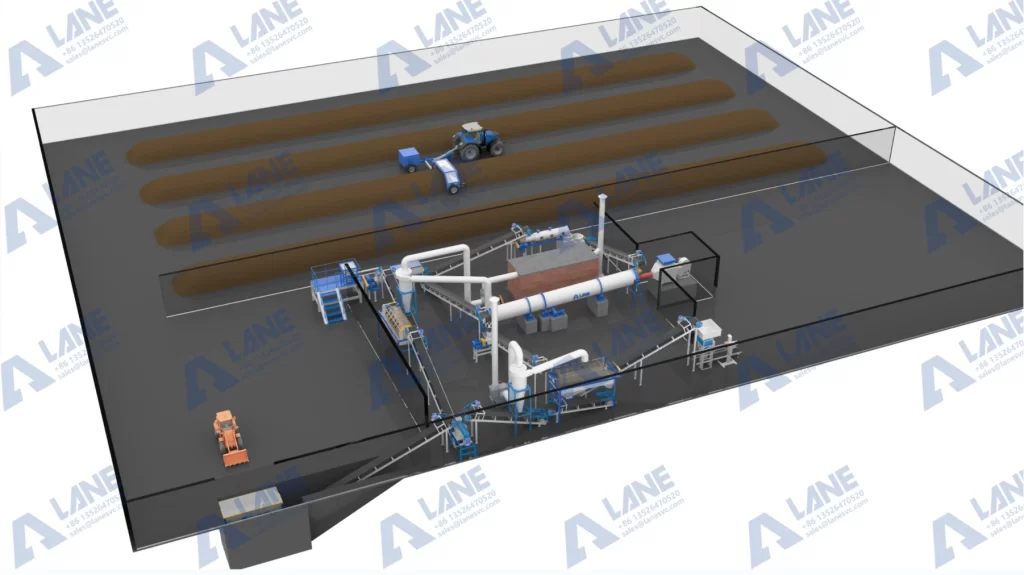

The Core Processing Flow of Bio-Organic Fertilizer Production from Agricultural Waste

Unlike simplistic compost heaps, a bio-organic fertilizer production from agricultural waste plant requires precision. Here’s how it unfolds in practice:

(1) Pre-treatment and Crushing

Collected waste first passes through a crushing machine to reduce particle size. Crop stalks and husks are shredded to improve aeration and accelerate microbial activity. Uniformity at this stage ensures smooth downstream processing.

(2) Mixing for Nutrient Balance

The crushed waste is transferred to a horizontal mixing machine, where carbon-rich crop residues are blended with nitrogenous manure. Sometimes, beneficial microbes or bio-additives are introduced. This tailored recipe sets the stage for stable fermentation.

(3) Aerobic Fermentation in Vertical Fermentation Tank

This is where waste begins its true transformation. Inside the vertical fermentation tank, oxygen supply, temperature, and moisture are carefully managed. Unlike open composting piles, enclosed tanks provide:

Faster decomposition (15–20 days instead of months)

Pathogen elimination through controlled thermophilic phases

Minimal odor leakage

LANE’s tank design allows operators to adjust aeration and mixing through automated control panels, reducing human error and ensuring consistency.

(4) Compost Turning for Uniform Decomposition

Even with tanks, large-scale operations often require a compost turner machine to re-aerate material and prevent anaerobic zones. Our crawler type compost turner is built for maneuverability inside organic fertilizer plants, ensuring even microbial activity throughout the pile.

(5) Screening for Quality Control

After fermentation, material is screened using a rotary screening machine. This separates fine, ready-to-use compost from larger, undecomposed particles that are returned to the process.

(6) Granulation and Polishing

Here’s where the product takes its market-ready form. The semi-finished compost is fed into an organic fertilizer granulator, followed by a polishing machine for uniform, round granules. Granules are more convenient for application, transportation, and storage.

(7) Drying and Cooling

To reduce moisture and increase shelf life, the granules pass through a rotary drum dryer and then a cooling machine. This step preserves microbial integrity while preparing the fertilizer for packaging.

(8) Final Packaging

The finished product is packed into bags by an automatic packing machine. LANE’s automated bagging solutions ensure accurate weight, speed, and minimal labor requirements, critical for scaling up production.

Benefits of Bio-Organic Fertilizer Production from Agricultural Waste

The benefits of bio-organic fertilizer production from agricultural waste extend far beyond simple waste recycling. At its core, it involves transforming crop residues, animal manure, and other by-products into valuable soil conditioners, significantly enhancing soil fertility. This circular utilization approach ensures that nutrients return to the land, reducing reliance on chemical inputs.

Another key benefit lies in environmental management. Unlike burning or discarding agricultural waste, which typically releases greenhouse gases and causes pollution, agricultural waste can be reused through controlled composting and fermentation. This process can reduce the carbon footprint, minimize odors to the greatest extent, and protect water resources by reducing nutrient loss.

For farmers, this also has economic benefits. By producing reliable bio-organic fertilizers from agricultural waste, they can reduce input costs and enhance their resilience to fluctuations in fertilizer prices. Moreover, healthier soil and balanced nutrient release help increase yields and crop quality, thereby creating long-term value. From a broader perspective, this production model has also promoted rural development. It has created opportunities for local industries, generated new jobs in the field of waste collection and treatment, and facilitated cooperation between technology providers like LANE and agricultural communities. Essentially, it is not merely a waste management strategy but also an engine for sustainable agricultural growth.

Comparison: Bio-Organic Fertilizer vs. Traditional Chemical Fertilizer

| Feature | Bio-Organic Fertilizer | Chemical Fertilizer |

| Source | Derived from agricultural waste, manure, and organic materials | Manufactured from synthetic chemicals |

| Nutrient Release | Slow and consistent, providing long-term benefits to soil health | Fast-acting but can cause nutrient leaching |

| Soil Health | Improves soil structure, boosts microbial activity, and enhances water retention | Can lead to soil degradation and reduced microbial diversity |

| Environmental Impact | Eco-friendly; reduces waste, lowers greenhouse gas emissions | High environmental impact; contributes to pollution and water contamination |

| Nutrient Balance | Rich in organic matter and micronutrients that enhance soil fertility | Primarily focused on macronutrients (N, P, K) |

| Sustainability | Contributes to a circular economy and sustainable farming practices | Dependent on fossil fuels, non-renewable resources |

| Cost-Effectiveness | Cost-effective in the long run by reducing dependency on external inputs | Often more expensive due to dependency on non-renewable raw materials |

| Long-Term Benefits | Builds soil fertility, reduces reliance on chemical inputs, and improves crop resilience | Provides quick fixes but can cause long-term soil depletion and health issues |

Key Insights:

Soil Health: Bio-organic fertilizers not only provide essential nutrients but also improve soil structure. Over time, they help soil retain moisture and increase biodiversity, which is essential for sustainable farming.

Sustainability and Environment: Unlike chemical fertilizers, which can leach into water bodies and pollute the environment, bio-organic fertilizers enhance soil organic matter, which helps sequester carbon and prevents nutrient runoff.

Cost-Effectiveness: While chemical fertilizers might seem cost-effective initially, their long-term environmental costs and dependency on external sources often lead to higher operational costs. Bio-organic fertilizers, on the other hand, offer an affordable, self-sustaining option.

Farmer Resilience: With bio-organic fertilizers, farmers are less vulnerable to fluctuating market prices for chemicals. They are also able to rely on local resources, turning agricultural waste into a valuable commodity, which further strengthens their farming operations.

LANE’s Competitive Edge

LANE isn’t just a machinery supplier; we’re a solution provider. Clients who approach us with raw material challenges often walk away with a turnkey bio-organic fertilizer production line that:

Optimizes energy consumption through smart equipment layout

Reduces operator dependency with automation and digital monitoring

Provides after-sales technical support, including remote diagnostics

Ensures compliance with local environmental regulations

For instance, in one Southeast Asian project, farmers had an excess of rice husks and poultry manure. LANE’s engineers, led by Oliver and Waylon, reworked equipment designs multiple times to ensure husks decomposed effectively without clogging. The result was a fully functional production line that now supplies bio-organic fertilizer across the region.

Frequently Asked Questions (FAQ)

Q1: How long does the bio-organic fertilizer production process take?

Generally, it takes 20–30 days from raw material pre-treatment to finished granules, depending on the fermentation system used.

Q2: Can the production line handle multiple types of agricultural waste simultaneously?

Yes. Our mixing and fermentation systems are designed to accommodate different waste streams, allowing blended formulations.

Q3: What is the capacity range of LANE’s production lines?

From small-scale plants (5,000 tons/year) to large industrial facilities (100,000+ tons/year). Each system is customized.

Q4: Is the final fertilizer certified organic?

LANE’s equipment is designed to meet organic standards, but certification depends on local regulations and input materials.

Looking Ahead: The Future of Agricultural Waste Utilization

As global food demand continues to increase, it has become increasingly important to utilize agricultural waste as a resource. In the future, agricultural waste will play a core role in sustainable agricultural practices, promoting the production of bio-organic fertilizers and fostering a circular agricultural economy. Agricultural waste will no longer be considered as a by-product, but will be regarded as a valuable resource that can be used to enrich soil, increase crop yields, and reduce environmental pollution.

Technological innovation will be the key to this transformation. LANE’s automatic composting turner, vertical fermentation tanks, and intelligent monitoring systems are making the composting process faster, more efficient, and more environmentally friendly. Through the integration of artificial intelligence and machine learning, farmers will be able to optimize every stage of production, ensuring the production of higher-quality biological fertilizers and increasing yields.

Furthermore, the government’s incentive measures and the enhancement of global awareness will continue to drive the transition towards sustainable practices. Policies supporting organic agriculture and waste-to-fertilizer technologies will further promote the adoption of these practices, creating growth opportunities for both local and global markets.

In conclusion, driven by technological innovation, sustainable development, and policy support, the future of agricultural waste utilization looks very promising. With the advanced solutions provided by LANE, the agricultural sector can transform waste into valuable resources, benefiting farmers and the environment.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520