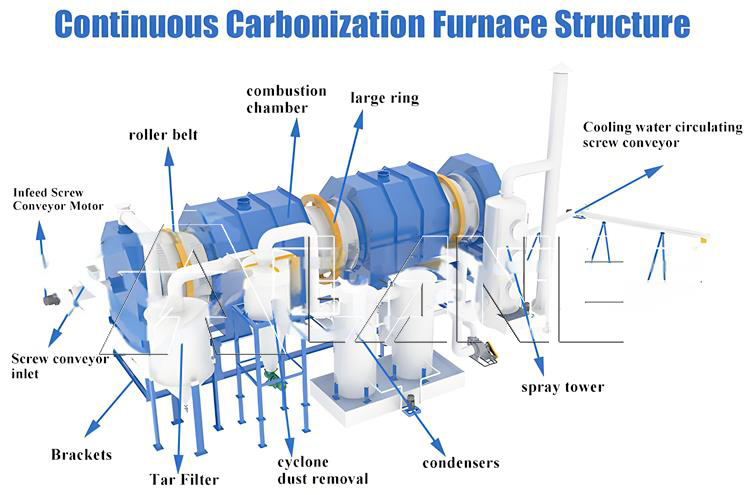

The continuous coconut shell carbonization machine is an environmentally friendly carbonization equipment, belonging to the continuous environmentally friendly carbonization device. The complete set of equipment consists of a gasifier, separator, purification furnace, induced draft fan, coconut shell carbonization host, spiral feeder, cooling discharge machine and other parts.

LANE can customize a coconut shell carbonization furnace for you to meet any of your needs.

Coconut shell carbonization machine |

||||

|---|---|---|---|---|

| Model | Production (kg/hour) | power | Drive form | Dimensions (L × W × H) |

| TDICA0.6 | 300-500 | 5.5 | Frequency Control | 10*1.1*1.2 |

| TDICA0.8 | 400-600 | 7.5 | 12*1.3*1.5 | |

| TDICA1.0 | 500-800 | 11 | 12*1.5*1.7 | |

| TDICA1.2 | 700-1200 | 15 | 14*1.7*1.8 | |

Firstly, the coconut shell is crushed and carbonized using a continuous coconut shell carbonization machine. The combustible gas generated by the gasification furnace is first ignited to produce gas, and then the combustible gas generated during the carbonization process is subjected to secondary combustion. The heat generated by the self is continuously recycled to burn the self. In addition, after purification treatment, the flue gas in the production environment is completely free of flue gas, meeting the national waste gas discharge standard.

According to user needs, there are two types of coconut shell carbonization machines: single row continuous coconut shell carbonization machine and double row continuous coconut shell carbonization machine. The double row continuous coconut shell carbonization machine can be controlled automatically by PLC. The unique features of the continuous coconut shell carbonization machine are – green and environmentally friendly, high efficiency and high yield, energy saving and low consumption, and continuous production.

It is an environmentally friendly carbonization equipment, belonging to a continuous environmentally friendly carbonization device. The equipment consists of a gasification furnace, separator, purification furnace, induced draft fan, coconut shell carbonization host, spiral feeder, cooling discharge machine and other parts of the production line. It is powered by an electric motor and uses self generated gas as fuel to ignite the flame of the stove and heat the bottom of the host. The coconut shell is dried under negative pressure in the cylinder, and carbonized under positive pressure oxygen deficiency.

The coconut shell carbonization machine adopts the dry distillation carbonization method, fully utilizing the combustible gases such as carbon monoxide, methane, and hydrogen generated during the carbonization process. Through the flue gas purification system, wood tar and wood acid liquid are separated to obtain pure combustible gases, which are then fully burned by the self equipped air burner to heat the high-temperature carbonization pipeline (generally controlled at around 600 ℃).

There are four layers of pipes inside the carbonization machine from top to bottom. The first and second layers are preheating and drying pipes, the third layer is low-temperature carbonization pipe, and the fourth layer is high-temperature carbonization pipe. The first and second floors are equipped with independent exhaust pipes to mainly discharge water vapor. The pipes use the waste heat in the furnace to dry the materials, and the water vapor is discharged from the exhaust pipes.

The third and fourth floors are also equipped with independent combustible gas recovery pipelines. The carbonization pipelines carry out high-temperature carbonization of materials, decomposing combustible gases such as carbon monoxide, methane, and hydrogen. The pipelines are heated through the recovery pipeline, flue gas purification system, and burner combustion, achieving the effect of reciprocating heating and carbonization. The initial carbonization ignition gas source is supplied by the biomass gasifier.

For more information, please contact us by sending an inquiry today! We can help you!

Efficiency

Compared to traditional intermittent carbonization furnaces, continuous carbonization furnaces can achieve continuous production and greatly improve production efficiency.

Extensive use

Coconut shell charcoal can be used in multiple fields such as metallurgy, non-ferrous metal production, formed fuels, and activated carbon manufacturing.

Energy conservation and environmental protection

Adopting advanced heat recovery technology and exhaust gas treatment equipment to reduce energy consumption, waste generation, and emissions.

World-class and Energy-saving Operation, Factory Price & Fast Delivery.