For producers seeking sustainable profitability, a cost-effective organic fertilizer machinery production line is not only a technical asset, but also a strategic investment. In today’s agriculture-dominated economy, maximizing yields and minimizing input costs are the cornerstones of successful farming and fertilizer production. With the growing global demand for organic agricultural products and increasingly stringent environmental policies, having a set of cost-effective machinery is no longer optional, but essential.

A cost-effective organic fertilizer machinery production line strikes a perfect balance between affordability, operational efficiency, and product quality.

(1) Meeting the growing demand for organic fertilizers

The global shift towards organic farming has led to an exponential growth in the demand for organic fertilizers. Consumers are increasingly demanding food that is free of harmful chemicals, and farmers are responding by adopting organic farming practices. This has created a huge opportunity for those involved in organic fertilizer production. However, to capture this opportunity, a cost-effective production process is essential. A cost-effective line of organic fertilizer machinery, such as those offered by LANE, can help producers meet the growing demand while controlling production costs. This not only ensures profitability, but also makes organic fertilizers more accessible to a wider range of farmers.

(2) Environmental Benefits & Sustainability

One of the main benefits of organic fertilizers is their positive impact on the environment. They reduce soil degradation, minimize water pollution, and promote healthier ecosystems. By investing in a cost-effective line of organic fertilizer machinery, producers can not only promote environmental sustainability, but also position themselves as leaders in the green revolution. LANE’s machinery is designed with sustainability in mind, using energy-saving technologies and minimizing waste generation. This not only helps reduce carbon footprint, but also brings long-term cost savings.

(3) Long-term cost savings

While the initial investment in an organic fertilizer machinery line may seem expensive, long-term cost savings are also critical. LANE’s high-quality, cost-effective machinery line can reduce production costs in a number of ways. For example, it can increase production efficiency, reducing the time and labor required to produce a given amount of fertilizer. It can also improve the quality of the fertilizer, which can increase farmers’ yields and potentially result in higher profits for producers. In addition, LANE’s machinery is built to last, reducing the need for frequent replacement and maintenance, leading to further long-term cost savings.

Investing in a well-designed organic fertilizer machinery production line can not only reduce initial capital expenditures, but also reduce long-term operating costs. From composting units and crushers to granulators, dryers, cooling systems, and packaging units, each component plays a role in reducing waste and improving resource utilization.

Not all machinery lines marketed as “cost-effective” truly live up to their promise. Genuine cost-effectiveness goes beyond price tags. It involves:

Energy efficiency: Machines optimized to consume less electricity or fuel

Automation: Systems with automated feeding, dosing, and monitoring to reduce labor costs

Modular design: The ability to expand or reconfigure the line based on production scale

Durability: Components built to last, minimizing downtime and replacement frequency

Low maintenance: Easy-to-clean, accessible designs that require fewer service interventions

A truly cost-effective organic fertilizer machinery line integrates all these aspects, delivering value over time.

Establishing a cost-effective organic fertilizer machinery line requires more than just purchasing basic equipment. It also requires choosing the right combination of equipment to maximize production while minimizing energy consumption, maintenance costs, and labor input. The following will take a closer look at each key component and how they can improve operational efficiency and achieve long-term cost savings.

(1) Fermentation/Composting System: Optimizing Microbial Activity

The fermentation stage is the biological foundation of any organic fertilizer production line. Efficient systems such as groove type compost turners, crawler type compost turners, and vertical fermentation tanks accelerate microbial decomposition by maintaining proper oxygen levels, temperature, and moisture content.

Cost-saving tip: Automated turning systems significantly reduce labor costs and improve aeration consistency, shortening composting time from months to as little as 15-20 days.

LANE advantage: LANE’s vertical fermentation tanks are equipped with intelligent control panels that monitor and adjust parameters in real-time for optimal fermentation.

(2) Crushing Equipment: Energy-Efficient Particle Reduction

After fermentation, bulky and uneven compost must be crushed to uniform sizes for effective granulation. LANE provides semi-wet crushers and vertical shaft crusher known for their high throughput and minimal energy usage.

Why it matters: Uniform particle size ensures better mixing and granulation, while reducing wear on downstream equipment.

Cost advantage: LANE crushers come with durable wear-resistant components that require less frequent maintenance, lowering operational costs over time.

(3) Mixing and Blending Units: Nutrient Uniformity at Scale

The mixing unit plays a pivotal role in ensuring the even distribution of macro and micronutrients in every batch. Whether you’re incorporating NPK additives, biochar, or trace minerals, precision blending is essential.

LANE innovation: Our twin shaft mixers and horizontal mixers come with anti-leakage sealing systems and paddle-speed optimization, reducing material loss and enhancing blending homogeneity.

(4) Granulation Machines: Flexible, Efficient, and Productive

Granulation is where the raw materials are shaped into marketable products. Disc granulators, rotary drum granulators, and new type organic granulators are commonly used, each with their own strengths.

Disc granulators: Ideal for small-to-medium scale plants, offering low cost and easy operation. It is also very suitable for cat litter production lines.

Rotary drum granulators: Suitable for larger capacities, with high production output and durable performance.

New type organic granulators: Especially efficient for pure organic materials, using high-speed mechanical agitation.

LANE flexibility: We help clients select and fine-tune granulators according to feedstock types and desired particle size—ensuring optimal energy use per ton of product.

(5)Drying & Cooling Systems: Preserving Quality, Reducing Waste

Post-granulation, the moisture content must be reduced to ensure product stability. LANE’s energy-saving rotary dryers work in tandem with counter-flow coolers to stabilize fertilizer granules and prevent caking.

Key feature: Our systems recover and recycle heat wherever possible, cutting energy bills by up to 25%.

Extra benefit: Reduced moisture also improves storage lifespan and reduces the risk of microbial contamination.

(6) Screening Equipment: Assuring Uniformity

Effective screening eliminates oversized and undersized granules, ensuring uniformity that meets customer and market expectations. LANE rotary screen machines are designed for minimal vibration and long service life.

Why important: Uneven particles can reduce perceived quality and compromise the nutrient balance of field application.

Cost-efficiency: LANE screens include automatic cleaning brushes, reducing downtime and manual cleaning needs.

(7) Packing Machines: Automation for Accuracy and Speed

Once the fertilizer is processed, accurate and efficient packaging becomes critical. LANE’s auto-weighting packing machines with high-speed bagging options reduce human error and increase throughput.

Smart integration: Available with PLC control and touchscreen interfaces, our machines handle various bag sizes, integrate with labeling systems, and operate seamlessly with conveyor systems.

(8) Optional Components for Further Optimization

To improve product quality and meet diverse customer needs, producers may also integrate:

Coating machines to reduce dust and enhance granule appearance.

Dust collection systems to improve plant hygiene and reduce air pollution.

PLC-integrated control centers for real-time monitoring of the entire production line.

Each of these components contributes to building a cost-effective organic fertilizer machinery production line. The key is synergy – ensuring that each piece of equipment not only operates efficiently, but also integrates smoothly with the rest of the system.

With LANE’s custom machinery solutions, customers around the world benefit from our experience, innovation, and commitment to sustainability and profitability. We provide comprehensive support, including layout design, custom machinery configuration, and on-site installation and training, ensuring a lasting return on your investment.

At LANE, we specialize in providing cost-effective organic fertilizer machinery production lines that meet the specific needs of our customers around the world. Our systems are not only affordable, but also provide excellent performance and durability. What sets us apart:

Customized Solutions: We design machinery lines based on your capacity, raw materials and budget. Whether you are starting small or expanding, LANE can provide tailor-made solutions.

Reliable Components: Every component in our machinery line is manufactured from wear-resistant materials and tested to stringent standards to ensure top performance even in the harshest environments.

Energy and Labor Efficiency: Our lines come equipped with intelligent control systems, helping you save on both energy and manpower. From auto-feeding to temperature monitoring, our technology reduces the need for constant supervision.

After-Sales Service: Each LANE organic fertilizer system is backed by a five-year comprehensive warranty. After delivery, certified engineers will visit the site to guide installation, perform precision commissioning, and conduct on-site training for operators and maintenance personnel. Throughout the warranty period, we provide remote technical support and regular on-site service to ensure continuous, trouble-free operation of the system.

Environmental Compliance: We prioritize sustainability. Our designs are in compliance with local environmental regulations, including odor control, noise reduction, and waste recycling.

Global Reach: LANE has successfully installed fertilizer production lines in regions like India, Egypt, Nigeria, Indonesia, and South America. Our multilingual team ensures smooth communication and localized support.

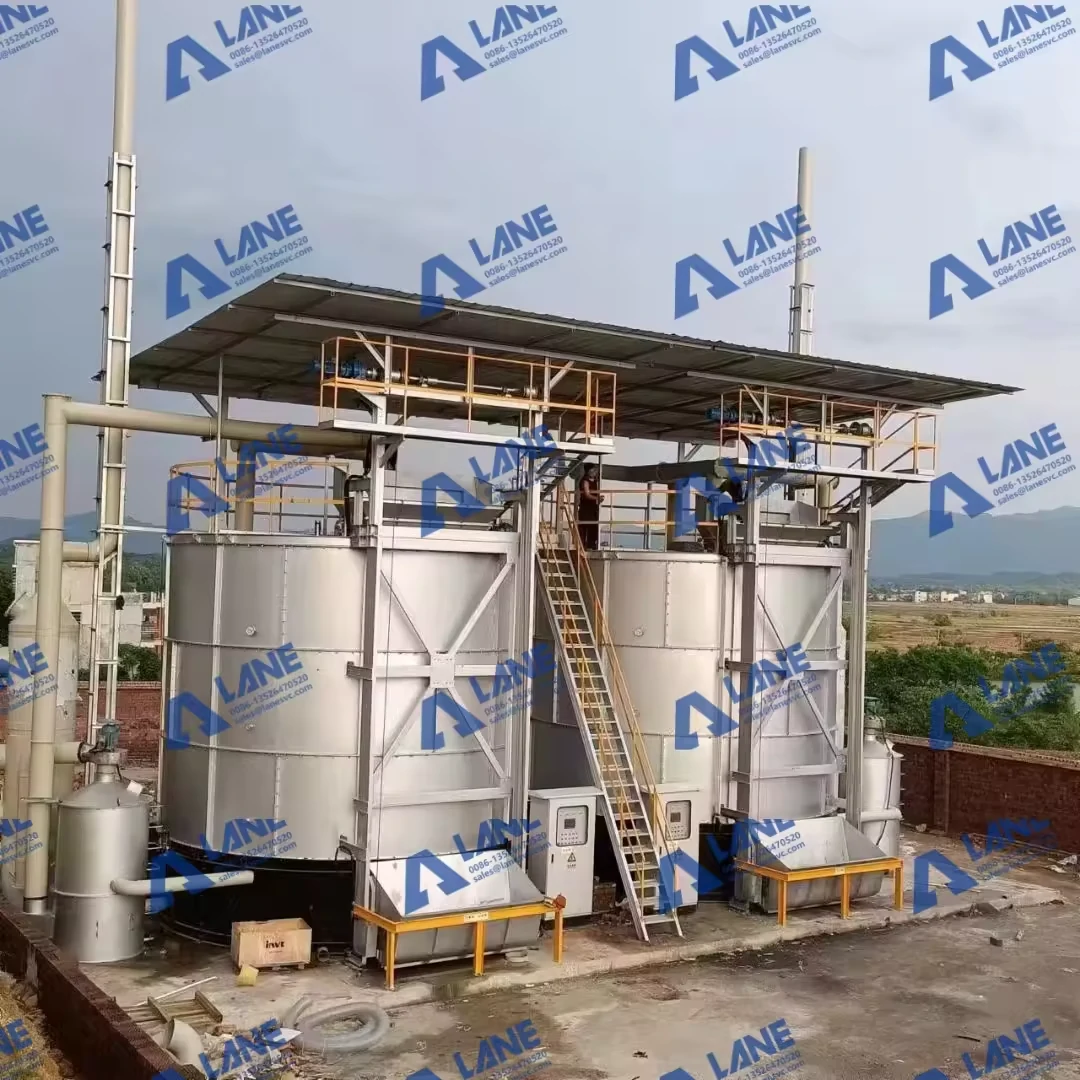

Case 1: SSP and Organic Fertilizer Line in India

In 2024, LANE worked with a large agricultural cooperative in Maharashtra, India, to build a mixed SSP (Dicalcium Monophosphate) and organic fertilizer production line. Due to rising local electricity prices, the customer sought a cost-effective solution with minimal energy consumption. We designed a compact, fully automated system that combines composting, phosphate concentration, granulation and packaging. Since then, the plant has doubled its production while reducing energy costs by 25%, and currently supplies more than 15,000 tons of fertilizer per year to the surrounding area.

Case 2: Organic Fertilizer Plant in Tanzania

LANE installed a medium-sized organic fertilizer production line for an agricultural alliance in Arusha, Tanzania. The alliance focuses on composting crop residues and livestock manure and needs a reliable modular production line to cope with seasonal changes in raw materials. The LANE team delivered a production line that includes a windrow turner, chain crusher, horizontal mixer and drum granulator. The production line currently serves more than 2,000 hectares of farmland, has created local jobs, and has been recognized by local agricultural institutions.

A cost-effective organic fertilizer machinery line does not mean cutting corners—it means making smart choices. Choosing low-quality machinery might offer short-term savings, but it leads to frequent breakdowns, lower output, and higher repair costs in the long run. Conversely, investing in a robust system like LANE’s ensures:

Higher production efficiency

Lower operating costs

Consistent product quality

Easy adaptability to future expansions

The return on investment (ROI) is realized faster when the system operates with fewer stoppages, produces higher yields, and meets regulatory standards without additional upgrades.

As the global agricultural industry transitions to a more sustainable model, the demand for organic fertilizers will continue to grow. Producers must be ready to meet this demand with reliable, scalable, and environmentally friendly equipment. Investing in a cost-effective organic fertilizer machinery production line now is a critical step to ensure your future competitive advantage.

Technological advances such as IoT integration, automated quality inspection, and hybrid drying systems are shaping the next generation of fertilizer production. At LANE, we stay ahead of these trends to ensure your investment is not only viable today, but can adapt to future innovations.

In conclusion, a cost – effective organic fertilizer machinery production line is a valuable asset for anyone involved in the production of organic fertilizers.This cost-effective organic fertilizer machinery production line is more than a collection of machines—it’s the backbone of a modern, sustainable, and profitable fertilizer business. With LANE as your equipment partner, you gain access to world-class engineering, dependable service, and innovative technology tailored to your needs.Take the smarter path to organic fertilizer production.

Choose LANE. Choose efficiency. Choose growth.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520