In modern sustainable agriculture, cow manure granular organic fertilizer is emerging as one of the most valuable tools for farmers seeking to improve soil fertility and crop productivity while reducing environmental impact. Instead of letting cow manure pile up and cause pollution, farmers can transform it into nutrient-rich granular organic fertilizer using advanced production lines. At LANE, we specialize in delivering complete cow manure granular organic fertilizer production lines that help farms maximize the value of their manure, create high-quality fertilizer products, and open new revenue streams.

Cow manure granular organic fertilizer offers a slow-release nutrient source that improves soil structure, boosts microbial activity, and enhances water retention. Unlike chemical fertilizers, which release nutrients quickly, cow manure pellets release nutrients slowly, promoting more sustainable crop growth and reducing nutrient loss into waterways. Furthermore, processing cow manure into granules makes it easier to store, transport, and apply evenly to fields, whether for large-scale or small-scale farming.

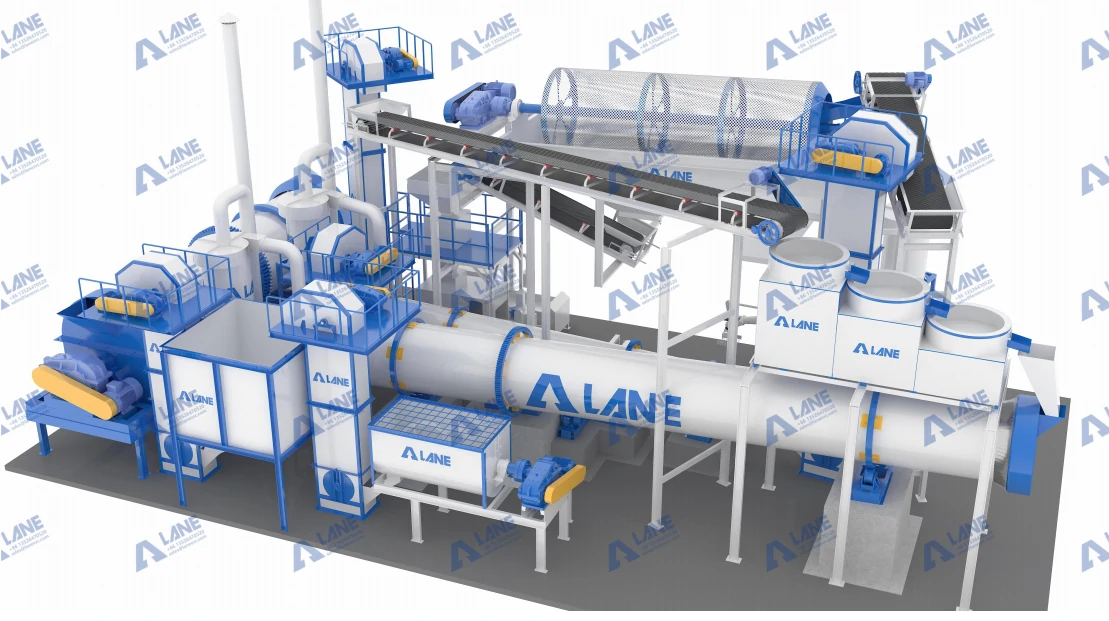

A high-quality cow manure granular organic fertilizer production line involves multiple stages of processing, each designed to ensure maximum efficiency and product quality.

| Step | Description | LANE’s Advantages |

| Fermentation | Cow manure is aerobically composted to kill pathogens and stabilize nutrients. | LANE provides crawler type, groove type, or wheeled compost turners for rapid, odor-free fermentation tanks. |

| Crushing | Dried compost is crushed to achieve uniform particle size. | High-efficiency semi-wet material crushers and vertical shaft crushers prevent clogging and reduce maintenance. |

| Mixing | Cow manure is blended with other nutrients or organic matter for a balanced formula. | Precision mixers ensure homogeneity and reduce nutrient loss. |

| Granulation | Materials are shaped into uniform granules. | LANE offers disc granulators, rotary drum granulators, and new-type organic fertilizer granulators for high yield. |

| Drying & Cooling | Removes excess moisture, hardens granules for storage. | Energy-efficient rotary dryers and coolers extend product shelf life. |

| Screening | Separates qualified granules from fines or oversize particles. | LANE’s vibrating screeners ensure size consistency for market acceptance. |

| Packaging | Finished products are bagged for storage and sale. | Automatic packing machines improve efficiency and accuracy. |

LANE’s systems are in operation across multiple continents, serving both large-scale farms and rural cooperatives.

Case Study 1 – Gujarat, India

A large dairy cooperative in Gujarat faced high waste management costs and limited fertilizer availability. LANE installed a cow manure granular organic fertilizer line capable of processing 20 tons of manure per day. Within the first year, chemical fertilizer purchases dropped by 45%, and the cooperative generated an additional $150,000 in sales from organic fertilizer.

Case Study 2 – Malang, Indonesia

In Malang, small dairy farmers formed a cooperative to share the cost of a LANE production line. By turning manure into granular fertilizer, they reduced environmental contamination in waterways and increased average crop yields by 22%.

Case Study 3 – Tanzania

A livestock farming group in Tanzania used LANE’s compact cow manure granulation system to produce affordable organic fertilizer for local vegetable growers, helping improve food security and creating new employment opportunities.

Investing in a cow manure granular organic fertilizer production line offers farmers and agricultural enterprises a powerful combination of financial returns and ecological improvements.

From an economic perspective, producing granular organic fertilizer from cow manure allows farms to turn what was once a costly waste disposal challenge into a profitable product. Instead of paying for manure transport or storage, farms can sell nutrient-rich pellets to neighboring farmers or local distributors. The shelf-stable nature of granules also means the fertilizer can be stored for longer periods without losing quality, enabling year-round sales and reducing price fluctuations. Many LANE clients have reported recovering their investment in as little as 12–18 months due to the steady revenue stream from fertilizer sales.

Operational efficiency also plays a role in cost savings. By using LANE’s automated systems, labor costs drop significantly, energy use is optimized, and downtime is minimized. This allows even small- to medium-scale operations to run competitively alongside larger agricultural producers.

From an environmental perspective, the impact is equally significant. Converting cow manure into granular organic fertilizer prevents nutrient runoff, which can otherwise pollute waterways and damage aquatic ecosystems. The controlled composting process kills harmful pathogens and stabilizes organic matter, making it safe for soil application. Granular fertilizers also release nutrients slowly, improving soil structure, increasing water retention, and promoting beneficial microbial activity.

Moreover, using organic alternatives reduces reliance on synthetic fertilizers, helping lower the carbon footprint of agriculture. By recycling manure into valuable fertilizer, farms contribute to a more circular agricultural economy—one where waste becomes a resource instead of a liability.

Investing in a cow manure granular organic fertilizer production line is not just an equipment purchase—it’s a sustainable agricultural strategy. With LANE’s expertise, you can convert farm waste into a profitable resource, reduce environmental impact, and strengthen your agricultural productivity for years to come. LANE is ready to help you build a customized, efficient, and profitable fertilizer production system. Contact us today to turn your manure into market-ready granular gold.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520