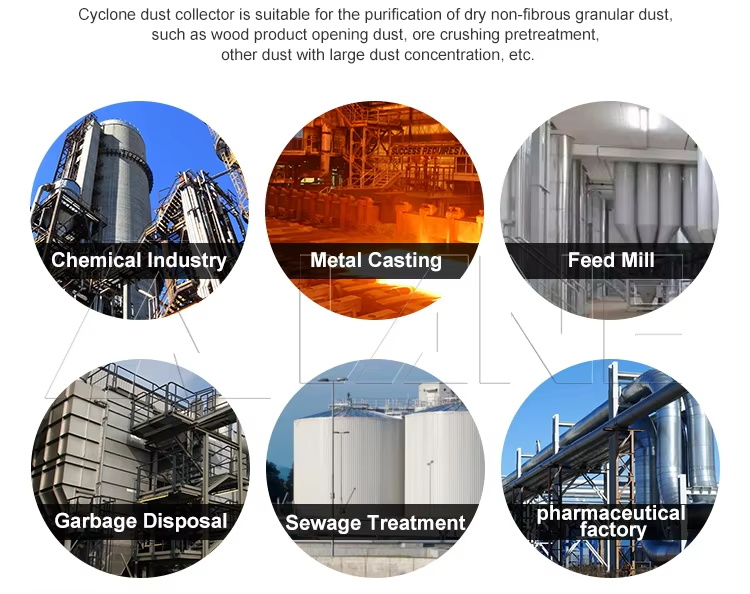

Cyclone dust removal is a device that uses the centrifugal force of rotating airflow to separate dust particles from gas. With its simple structure, easy maintenance, and large processing air volume, it plays an important role in multiple industrial fields.

LANE can customize a cyclone dust removal for you to meet any of your needs.

Cyclone dust removal |

|||

|---|---|---|---|

| Model | Diameter(mm) | Plate | Cylinder height(m) |

| LAXF-800 | 800 | 2.5 | 3 |

| LAXF-1000 | 1000 | 2.75 | 4.5 |

| LAXF-1000 | 1000 | 4.5 | 4.5 |

| LAXF-1200 | 1300 | 3 | 5 |

| LAXF-1300 | 1300 | 3.5 | 5 |

| LAXF-1500 | 1500 | 4 | 5 |

| LAXF-1500 | 1500 | 4.5 | 5 |

| LAXF-1800 | 1800 | 4 | 5 |

Cyclone dust removal is a commonly used air purification equipment, mainly used to remove dust and particulate matter generated in industrial production processes.

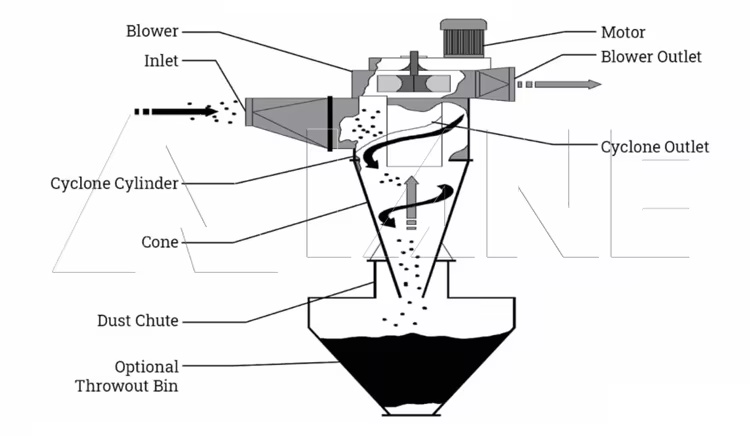

Its core working principle is to use the centrifugal force generated by the dust-laden airflow in the rotational motion to separate the dust particles from the airflow and capture them on the wall, and then use gravity to make the dust particles fall into the ash hopper.Specifically, when the gas containing particulate matter passes through the cyclone dust collector, the gas forms a rotating cyclone inside the cyclone dust collector. Due to the inertia of the particles, the particles will be separated by the centrifugal force, and the clean gas will be discharged from the top of the cyclone dust removal.

Generally speaking, the larger the particle size of the particles, the better the effect of the centrifugal force; the higher the concentration of the particles, the higher the dust removal efficiency. Therefore, when selecting and using a cyclone dust collector, it is necessary to make comprehensive considerations based on specific process conditions and environmental protection requirements.

For more information, please contact us by sending an inquiry today! We can help you!

Simple structure

The cyclone dust collector is mainly composed of an air inlet pipe, an exhaust pipe, a cylinder, a cone, an ash hopper, etc. It has a relatively simple structure and low manufacturing and maintenance costs.

Wide adaptability

The cyclone dust collector can adapt to different working conditions such as high temperature, high pressure, and high humidity. It can handle a variety of dust types and has a wide adaptability. It can operate stably in various industrial environments.

High dust removal efficiency

For large dust particles larger than 5 microns, the dust removal efficiency of the cyclone dust collector can generally reach more than 80%.

World-class and Energy-saving Operation, Factory Price & Fast Delivery.