Many people new to fertilizer production often ask about the difference between granulator and shredder. These two machines are both important, but they do very different jobs. If you choose the wrong one, the whole production line may not work smoothly.

In our company, we have focused on fertilizer machinery for more than 20 years. We help customers design equipment, build full production lines, and provide long-term service. From this experience, we know that understanding these two machines is a key first step.

When we talk about the difference between granulator and shredder, the most obvious point is their function.

The clearest difference between granulator and shredder is their main function.

A granulator is used to form fertilizer granules. It turns powder or fine material into uniform particles. These particles are easy to pack, transport, and apply in the field. Granulation also improves product value and appearance.

A shredder is used to reduce size. It breaks large or hard materials into smaller pieces. It does not shape the product. It only prepares the material for the next process.

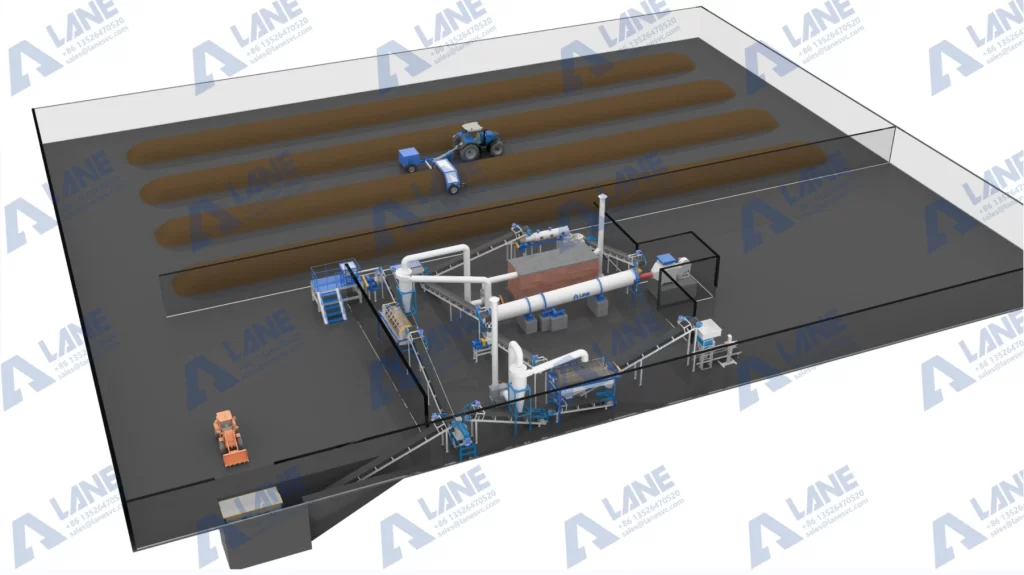

In many fertilizer plants we design, shredders are used at the front of the line, while granulators are used near the end. This order shows their different roles clearly.

Another important part of the difference between granulator and shredder is how each machine works during operation.

Another important difference between granulator and shredder is how they work internally.

A granulator works by rolling and pressure. Material moves inside the machine while rotating. With moisture and motion, small particles stick together and slowly grow into granules. The operator can control granule size by adjusting speed and feed rate.

A shredder works by cutting, crushing, or tearing. Strong mechanical force breaks the material into smaller pieces. Screens are often used to control the output size.

Our engineering team adjusts these working principles based on material type. This customized design helps customers get stable and efficient production.

From a structural view, the difference between granulator and shredder can be clearly seen in their core components.

Looking at the internal structure helps explain the difference between granulator and shredder.

A granulator usually includes a rotating shell or disc, lining plates, a drive motor, and sometimes a spraying system. These parts must work smoothly for long hours. Stability and balance are very important.

A shredder mainly includes blades or hammers, shafts, a strong frame, and a motor. These parts must handle impact and wear. Easy maintenance is a key design point.

All our machines are designed to meet ISO9001 and CE standards. This ensures safe operation and reliable performance over time.

To fully understand the difference between granulator and shredder, it is helpful to know the different types of granulators used in fertilizer production.

Drum granulators are very common. They are suitable for large-scale production and continuous operation. They work well with compound fertilizer and organic fertilizer. Many customers choose this type for stable output.

Disc granulators are simple in structure and easy to operate. They allow flexible control of granule size. This type is often used in organic fertilizer production lines. We often customize disc angle and size based on customer needs.

Double roller granulators are used for dry granulation. They do not require water or drying equipment. This helps reduce energy cost. They are widely used for compound fertilizer and special formula fertilizer.

Flat die granulators are common in organic fertilizer plants. They are compact and suitable for small and medium capacity. They work well with composted material.

Ring die granulators are designed for higher output and stronger granules. They are often used when customers want high-density fertilizer pellets.

With our experience, we help customers choose the right granulator type and integrate it into a complete production line.

The difference between granulator and shredder becomes even clearer when looking at shredder types.

Chain crushers are simple and cost-effective. They are often used for organic fertilizer and returned material crushing. Maintenance is easy, which makes them popular for small plants.

Hammer crushers use high-speed rotating hammers. They can handle harder materials such as mineral fertilizer. They provide strong crushing ability but require regular inspection.

Vertical crushers are widely used in fertilizer production lines. They save space and work efficiently with wet or sticky materials. Many customers prefer this type for stable feeding to the granulator.

Cage crushers are used for fine crushing. They are good for compound fertilizer and help improve granulation quality.

Our team selects shredder types based on material hardness, moisture, and capacity. This ensures smooth connection with downstream equipment.

In a fertilizer production line, the difference between granulator and shredder is not a competition. It is cooperation.

Shredders prepare the raw materials. Granulators shape the final product. If shredding is poor, granulation will be unstable. If granulation is poor, the fertilizer will be hard to sell.

We specialize in designing full fertilizer production lines. From equipment layout to on-site installation, we make sure both machines work smoothly together. Our after-sales team provides maintenance and technical support to keep production stable.

Understanding the difference between granulator and shredder also helps customers plan maintenance and upgrades.

Granulators need regular checks on bearings and liners. Shredders need blade inspection and replacement. Proper service extends machine life and improves efficiency.

We provide one-stop service, from design and manufacturing to installation and after-sales support. With over 20 years of experience, we help customers solve problems quickly and improve production performance.

The difference between granulator and shredder lies in function, structure, and role in the production line. One breaks material down. The other builds it up. Both are essential in modern fertilizer manufacturing.

With professional engineering, customized equipment, and full production line support, our company helps customers build reliable fertilizer plants that meet international quality standards and long-term business goals.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520