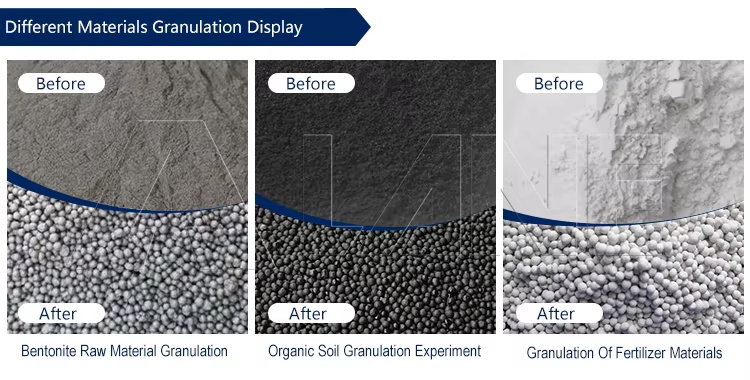

The disc granulator has wide adaptability to raw materials and is widely used in the processing of various fertilizers. It can also be used for the granulation of various raw materials such as compound fertilizers, chemicals, feed, coal, metallurgy, etc. LANE‘s disc granulator can be customized for you to meet your various needs.

Disc granulator |

||||||

|---|---|---|---|---|---|---|

| Model | Capacity(tph) | Size(mm) | Power(kw) | Rotation Speed(rpm) | Pan Diameter(mm) | Tilt Angle(°) |

| LAZD-500 | 0.05-0.1 | 650*600*800 | 0.75 | 32 | 500 | 35-55 |

| LAZD-1000 | 0.1-0.2 | 1800*1200*1600 | 3 | 25 | 1000 | 35-55 |

| LAZD-1200 | 0.2-0.4 | 2000*1400*1950 | 3 | 22 | 1200 | 35-55 |

| LAZD-1500 | 0.4-0.6 | 2200*1800*2050 | 4 | 20 | 1500 | 35-55 |

| LAZD-1800 | 0.6-0.8 | 2600*2000*2450 | 5.5 | 16 | 1800 | 35-55 |

| LAZD-2000 | 0.8-1 | 2900*2100*2750 | 7.5 | 16 | 2000 | 35-55 |

| LAZD-2200 | 1-1.5 | 2530*2100*2800 | 7.5 | 18 | 2200 | 40-50 |

| LAZD-2500 | 1.5-2 | 2630*2600*2800 | 7.5 | 16.2 | 2500 | 40-50 |

| LAZD-2800 | 2-3 | 2850*3020*3110 | 7.5 | 14.2 | 2800 | 40-50 |

| LAZD-3200 | 3-4 | 3600*3030*3310 | 11 | 13.5 | 3200 | 40-50 |

| LAZD-4000 | 4-5 | 4500*3300*4000 | 15 | 12.3 | 4000 | 45 |

| LAZD-4500 | 5-6 | 5100*3700*4400 | 22 | 10 | 4500 | 45 |

| LAZD-6000 | 6-10 | 6400*5000*6000 | 75 | 8.9 | 6000 | 45 |

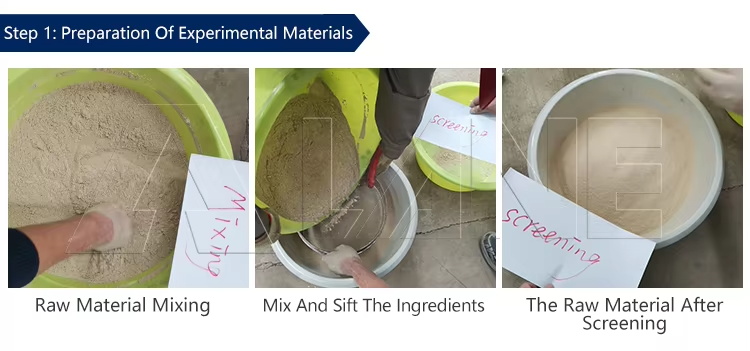

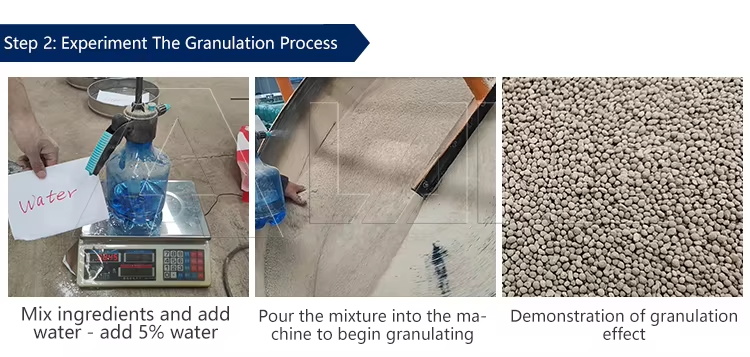

The working principle of a disc granulator is mainly based on the mechanical squeezing, rolling, and collision formed by the material in a rotating inclined disc, which causes the material to aggregate into particles of specific shapes.

Its core component is a rotating disc with a tilted angle, which is driven by an electric motor to rotate. The material is first crushed, screened, and mixed before being evenly added to the disc. Inside the disk, the material is subjected to a combination of centrifugal force, frictional force, and gravity, moving along a parabolic trajectory.

If you have a better idea, or would like to do an experimental test as well, please contact us right away!

High uniformity of granulation

The design of the disc granulator adopts an integral circular arc structure, and the granulation rate can reach over 93%. This structure ensures that the material is subjected to uniform force during the granulation process, resulting in the formation of high-quality particles.

The equipment runs smoothly and is durable

The base design of the disc granulator is thickened and weighted, ensuring the stability of the equipment during high-speed operation, reducing vibration, and thus extending the service life of the equipment.

Easy to operate and maintain

The structure of the disc granulator is novel and reasonable, reducing the complexity of operation, allowing operators to quickly get started and easily adjust the tilt angle of the large plate to meet different production needs.

World-class and Energy-saving Operation, Factory Price & Fast Delivery.