In today’s agricultural industry, Double Roller Granulator machines have become a cornerstone of efficient compound fertilizer and organic fertilizer manufacturing. This dry granulation technology offers a clean, energy-saving, and customizable solution for producing high-quality fertilizer granules.

LANE Heavy Industry, a professional fertilizer equipment manufacturer, provides a full range of Double Roller Granulators equipped with wear-resistant roller shells, customized accessories, and even Cummins motor options to meet various production needs around the world.

What Is a Double Roller Granulator?

A Double Roller Granulator (also called a dry extrusion granulator) is a compact, efficient fertilizer granulation machine. It works by compressing powdery materials between two rotating rollers that form the material into solid granules through mechanical pressure — without using any liquid binder or heat.

Unlike wet granulators, the double roller type requires no drying process, making it ideal for energy-efficient, continuous fertilizer production lines.

Typical Applications

NPK compound fertilizer

Urea-based or ammonium chloride-based fertilizer

Organic fertilizer and biofertilizer

Chemical and mineral powders

Feed or additive granulation

Structure and Working Principle

The LANE Double Roller Granulator consists of several precision-engineered components:

Feeding System – Feeds powder material evenly into the roller area.

Press Rollers (Roller Shells) – The heart of the machine. Two counter-rotating rollers compress the material into granules.

Transmission System – Connects the rollers with an electric motor and gearbox to maintain consistent torque and speed.

Crusher & Screening System – Breaks large agglomerates and separates fine powder for recycling.

Frame & Housing – Sturdy steel structure ensuring vibration-free operation.

Working process:

Powder enters the feeding zone → high pressure is applied between the two rollers → materials are compacted into sheets → sheets are crushed and screened → qualified granules are collected for packaging.

High-Quality Roller Shells (Roll Skins) and Custom Patterns

The roller shell is the most critical component of a Double Roller Granulator.

LANE uses alloy steel and stainless steel materials with advanced CNC machining and heat treatment technology to ensure:

Long wear life

Strong corrosion resistance

Precise granule patterning

Smooth compression for uniform particle size

Customers can customize the roller surface design to match their formula or product appearance.

Popular roller mold shapes include:

Oval, pillow, or irregular shapes

NPK patterns

Flat surface granules for ammonium chloride or ammonium sulfate

Each roller shell can last for thousands of working hours, and LANE provides one free set of spare parts (including roller skins or seals) for every complete machine order.

Customizable Components and Optional Power Systems

Every LANE Double Roller Granulator can be tailored to meet the customer’s factory environment and material requirements.

Available options include:

Customized roller patterns and material hardness

Carbon steel or stainless steel body for corrosion resistance

Variable speed control system for adjusting granule size and hardness

Cummins Motor Option — customers can select a Cummins diesel engine for enhanced power stability, especially useful in regions with unstable electricity

Adjustable pressure system — to optimize granule density

LANE’s R&D team can also design special rollers to suit high-salt or bio-organic materials to prevent corrosion and sticking.

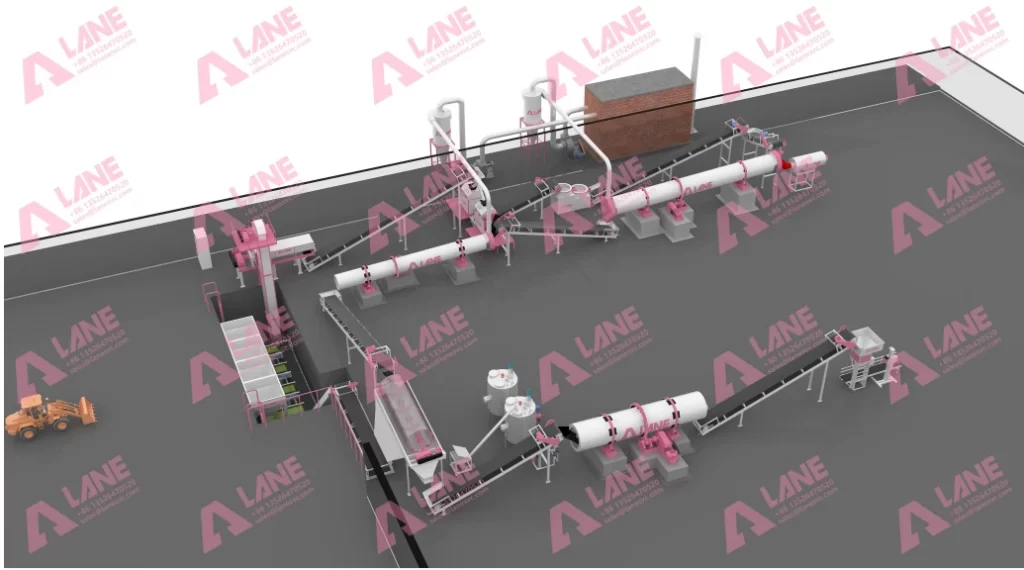

Production Process of Fertilizer with Double Roller Granulator

The Double Roller Granulator is typically used in a dry fertilizer granulation line.

A complete process includes:

Raw Material Batching: Ingredients like urea, ammonium sulfate, potassium chloride, and phosphates are accurately weighed using an automatic batching system.

Mixing: Materials are mixed evenly by a fertilizer mixer (e.g., horizontal or vertical mixer).

Granulation: The mixture enters the Double Roller Granulator, where high pressure transforms it into solid granules.

Crushing and Screening: Granules are sized properly using a rotary screener; oversized particles are crushed and recycled.

Coating and Packaging: Optional coating machine adds anti-caking protection before final packaging.

This line is simple, compact, and efficient, with low investment and quick return.

Key Advantages of LANE Double Roller Granulator

Dry granulation – No need for heating, drying, or water

Energy-saving – 40% less energy consumption than wet granulation

Compact and reliable structure – Easy installation and maintenance

High granulation rate – Over 85% qualified granules

Customizable roller molds – Match any formula or shape

Long lifespan – Hardened roller shells resist abrasion

Optional Cummins motor – Reliable and globally serviced

Free spare parts – One set provided per order

Wide adaptability – Works with both chemical and organic materials

Applicable Materials

The LANE Double Roller Granulator is compatible with a broad range of materials, such as:

Urea, ammonium sulfate, ammonium chloride

Potassium chloride, potassium sulfate

Phosphate and dolomite powder

Organic fertilizer powder (chicken manure, compost, etc.)

Bentonite, kaolin, zeolite

Feed and additive materials

This versatility makes it suitable for both small farms and industrial fertilizer plants.

Project Case: 10 T/H NPK Fertilizer Line in Indonesia

One of LANE’s recent projects involved a 10-ton-per-hour NPK fertilizer production line in Indonesia.

The customer required a fully automatic dry granulation system to process local raw materials.

LANE provided a complete solution with:

DZJ-4 Double Roller Granulator

Cummins diesel motor system (for off-grid operation)

Custom roller pattern for 4mm pillow-shaped granules

Automatic batching and screening system

After installation and training, the production line achieved a granulation rate of 90% and reduced operating costs by 30% compared to wet granulation.

After-Sales Support and Spare Parts Service

LANE ensures that every customer enjoys long-term technical and spare parts support.

Our service includes:

On-site installation and commissioning

Roller shell replacement and pattern customization

Maintenance training for local operators

Free spare parts and fast shipping

Remote video guidance and lifetime technical support

With global clients in India, Indonesia, Zambia, Nigeria, and South America, LANE has built a strong reputation for reliability and performance.

About LANE Heavy Industry

Henan LANE Heavy Industry Co., Ltd. is a leading manufacturer of fertilizer machinery specializing in:

Organic fertilizer production lines

Compound fertilizer production lines

Granulators (disc, rotary drum, double roller, and flat die types)

Compost turners and mixers

Our equipment is CE and ISO-certified and exported to more than 40 countries.

We focus on efficiency, durability, and customer satisfaction.

Conclusion

The Double Roller Granulator is a smart investment for any fertilizer manufacturer seeking a low-cost, high-efficiency dry granulation solution.

With its custom roller shells, free spare parts, and optional Cummins power system, it meets diverse customer demands from small-scale operations to industrial production lines.

If you’re planning to start or upgrade your fertilizer business, LANE’s engineering team is ready to provide turnkey solutions tailored to your specific needs.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520