In the current agricultural sector, energy efficient organic fertilizer plant design is not merely a technical choice, but rather an inevitable requirement for both economy and the environment. With the rising cost of energy and the increasing demand for sustainable agricultural practices, fertilizer manufacturers and agricultural cooperatives are seeking solutions that can not only reduce operating costs but also provide high-quality organic fertilizers. By integrating modern process engineering, automated control systems, and optimized layouts, producers can reduce energy consumption by up to 30% without sacrificing production output.

Key Principles of Energy Efficient Organic Fertilizer Plant Design

Optimized Plant Layout:

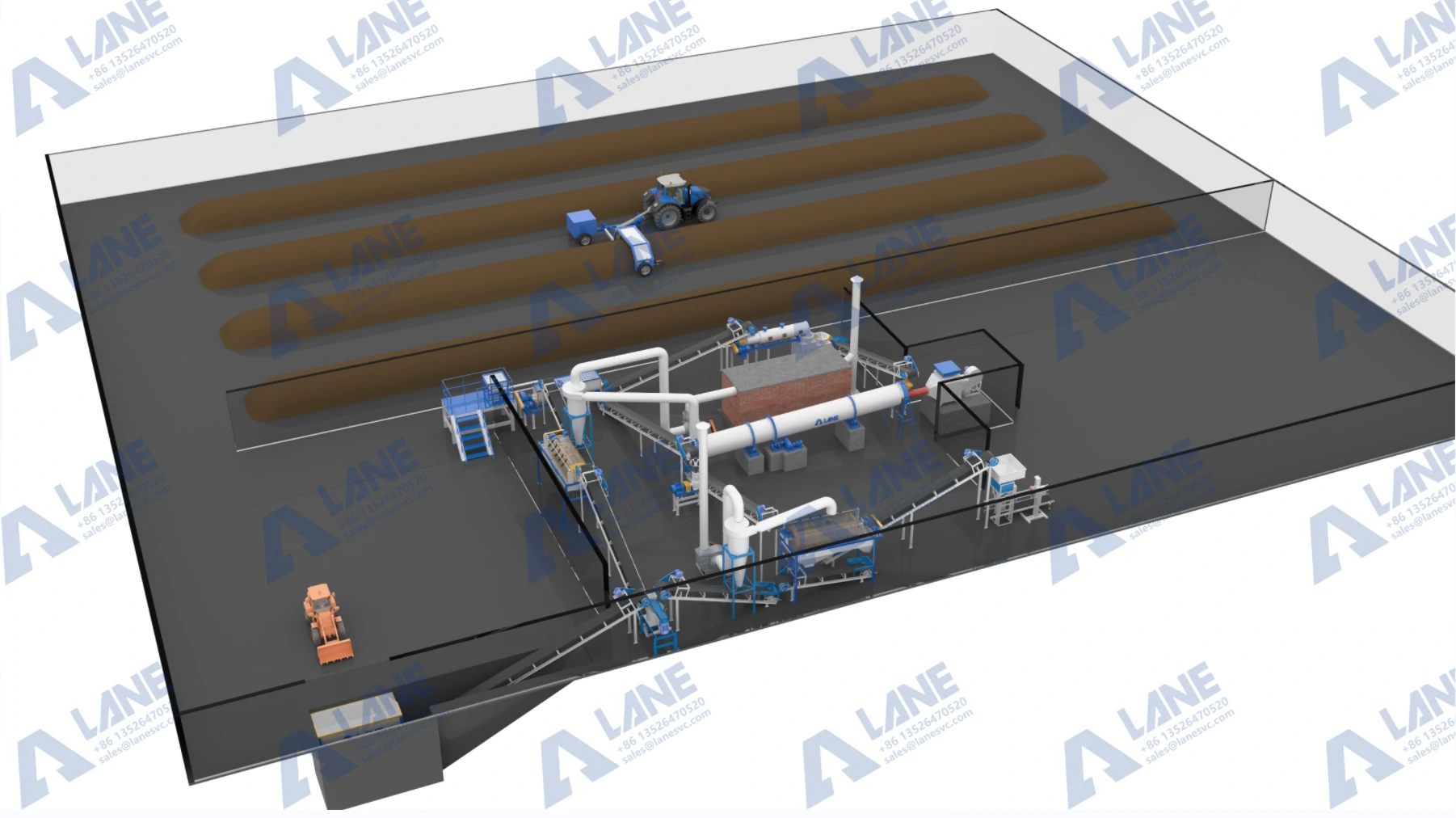

A well-planned energy efficient organic fertilizer plant design begins with smart facility layout. Shorter material transfer routes reduce conveyor power usage and minimize handling time. LANE’s engineering team designs plants that streamline raw material intake, composting, granulation, drying, and packaging into one smooth, continuous process.

Advanced Composting Technology:

In-vessel composting systems and high-efficiency compost turners accelerate the breakdown of raw organic materials with minimal power input. These systems maintain optimal temperature and moisture automatically, cutting down manual intervention and energy wastage.

Low-Energy Crushing and Mixing:

Using high-efficiency crushers and horizontal mixers helps reduce energy demand. LANE’s semi-wet crushers process manure, crop residues, and other organics without pre-drying, saving significant heat energy.

Energy-Saving Drying Systems:

Drying is one of the most energy-intensive steps in organic fertilizer production. Our energy efficient organic fertilizer plant design incorporates rotary drum dryers with waste heat recovery systems, allowing producers to reuse exhaust heat and lower fuel costs by up to 25%.

Typical Process Flow in Energy Efficient Organic Fertilizer Plant Design

| Step | Equipment | Energy-Saving Feature |

| Raw Material Reception | Loader, Conveyor | Short transfer distances to save conveyor energy |

| Pre-Treatment | Semi-Wet Crusher | Processes high-moisture material without pre-drying |

| Composting | Crawler Type Compost Turner | Automatic aeration reduces fuel use |

| Mixing | Horizontal Mixer | Fast blending reduces run time |

| Granulation | Double Roller Granulator | Dry granulation avoids heating |

| Drying | Rotary Drum Dryer with Waste Heat Recovery | Saves up to 25% fuel |

| Cooling | Rotary Cooler | Short cooling time lowers fan usage |

| Screening & Packaging | Rotary Screener, Auto Packer | Efficient motors and automation save power |

The typical process flow in energy efficient organic fertilizer plant design is built to minimize energy loss at every stage, from raw material handling to final packaging. By combining short transport routes, low-energy crushers and mixers, dry granulation equipment, and rotary dryers with waste heat recovery systems, the production line operates with significantly reduced power consumption. This approach not only lowers operating costs but also improves overall plant productivity and sustainability, ensuring that high-quality organic fertilizer is produced efficiently and profitably.

Case Study – Southeast Asia Organic Fertilizer Plant

A large-scale organic fertilizer producer in Southeast Asia partnered with LANE to implement a energy efficient organic fertilizer plant design. By replacing the traditional dryer with a waste heat recovery device, optimizing the layout to minimize the use of conveyors, and introducing dry granulation technology, the factory’s electricity consumption was reduced by 28%, and fuel consumption was decreased by 22%. The annual output remained stable at 50,000 tons, and the factory’s operating costs significantly decreased, resulting in an improvement in profitability in the first quarter.

Advantages of Choosing LANE for Energy Efficient Organic Fertilizer Plant Design

LANE has delivered projects in over 20 countries, providing tailor-made solutions for both small farms and large-scale fertilizer plants. Our expertise in energy efficient organic fertilizer plant design ensures:

Custom Capacity – From 5,000 to 200,000 tons/year.

Full Turnkey Service – From plant layout and process design to equipment installation and operator training.

Energy Optimization – Integration of low-power equipment, waste heat recovery, and intelligent automation.

Global Certification – CE, ISO, and other international quality approvals.

After-Sales Support – Spare parts, technical assistance, and process improvement services.

Future Trends in Energy Efficient Organic Fertilizer Production

The future of energy efficient organic fertilizer plant design will combine renewable energy sources such as solar or biogas with intelligent production control systems. AI-based monitoring will help regulate energy consumption in real time, adjusting equipment performance according to material moisture, temperature, and throughput needs. These innovations will make fertilizer plants not only greener but also more competitive in global markets.

Building a Profitable and Sustainable Future

Adopting sustainable production practices is no longer an optional upgrade—it’s becoming the standard for competitive and forward-thinking agricultural businesses. By rethinking facility design, integrating modern technology, and optimizing every stage of the production process, producers can achieve impressive cost savings while reducing their environmental footprint. Moreover, investing in smarter plant systems creates long-term stability. Lower operating expenses improve profit margins, while consistent product quality builds customer trust and loyalty. Such improvements not only strengthen your market position but also open opportunities for expansion, partnerships, and entry into higher-value markets.

With a commitment to innovation and operational efficiency, LANE can create a production model that delivers both financial rewards and environmental benefits—laying a solid foundation for sustainable growth for years to come.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520