A pellet production line is a complete set of equipment and mechanical components designed to achieve continuous or semi-continuous production from raw materials to pellets. These raw materials can include wood, biomass, animal feed and other materials that can be compressed and formed into small cylindrical pellets. Pellet production lines are used for different purposes in a variety of industries, including biomass energy, animal feed, etc.

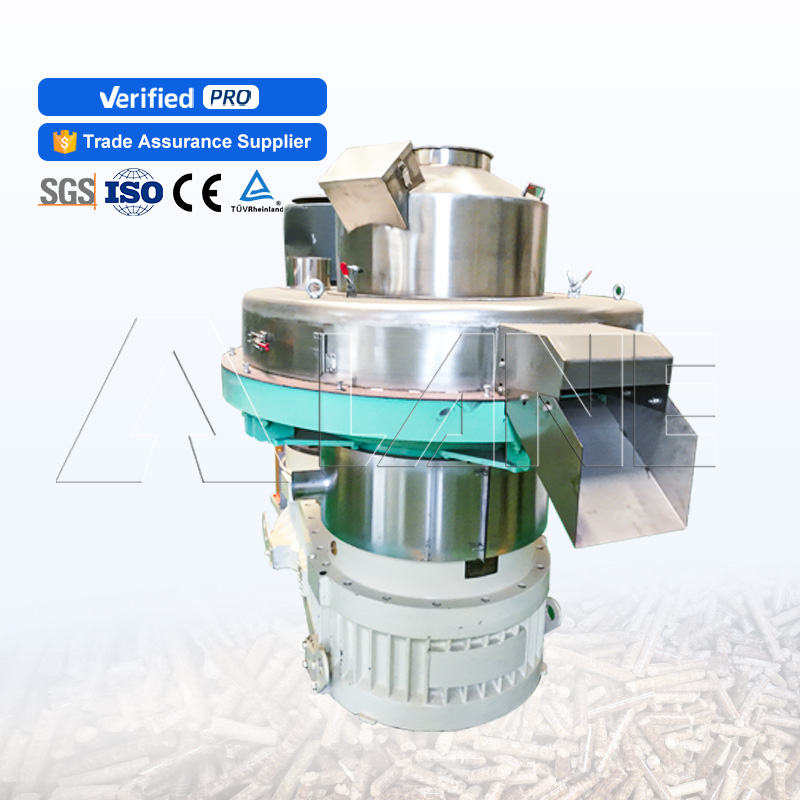

Granulation is the process of processing processed raw materials into compact, uniform-sized cylindrical particles. This is a key step in the granulation production line. Based on different production needs, we have different granulation equipment for you to choose.

Capacity: 200kg/h~2ton/h for wood;1ton/h~15ton/h for feed;

Raw materials: sawdust, straw, bamboo chips, bagasse, peanut shells

Capacity: 200kg/h~2ton/h for wood;1ton/h~15ton/h for feed;

Raw materials: sawdust, straw, bamboo chips, bagasse, peanut shells

Capacity: 50~600kg per hour for wood;60~1100 kg/h for feed;

Raw materials: sawdust, straw, bamboo chips, bagasse, peanut shells

Power:30--90KWDimension(L*W*H):1800*1100*1300 Application:Crush Wood Logs Making SawdustFinal product:1-10mm SawdustCertification:CE ISO

Power:15KWDimension(L*W*H):1000*100*100CMEvaporation Capacity(kg/h):20Material:SUS304 Application:Cooling and dryingCapacity:1.8-5t/hRotation speed(r/min):3-8rpmSloping speed:3-5

Dimension(L*W*H):CustomizeRaw material:Corn Soybean WheatCapacity:1000 kg/h Advantage:Easy Operation High Efficiencysize:230*190*270cm Certification:CE ISOSuit for:Cow.sheep.pig Goose.duck.chicken.etc

Post-pelletization processing is critical to ensure the final quality of the pellets. It is also an essential stage to produce high-quality pellets that meet industry standards and market demand.

Dimension:1100*1000*2600mmCore Components:PLCWeight per bag:5kg to 50kg per bag Application:Food, Beverage, Commodity, Chemical, Machinery & Hardware, Apparel

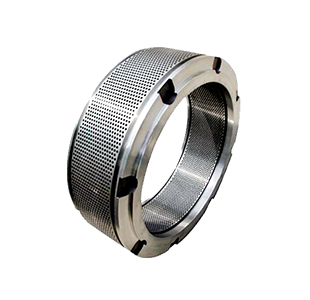

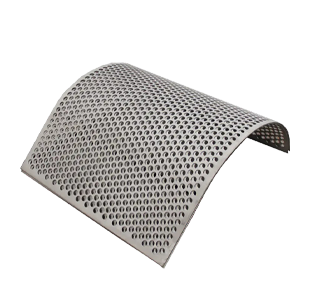

Ensure the longevity and performance of your pelletizing equipment with high-quality accessories such as ring dies, pressure rollers, and screens. Designed to complement and enhance your machines, these durable parts keep your production line running smoothly and efficiently. Boost productivity with reliable, industry-leading accessories.