The feed grinding and mixing machine produced by LANE is a multifunctional machine that integrates the functions of crushing and mixing. It is designed to process various materials such as corn, wheat, soybeans and grains to produce animal feed efficiently. The machine is widely used in livestock and poultry breeding industries as well as feed processing plants and is an important part of modern feed production lines.

Feed Grinding and Mixing Machine |

||||

|---|---|---|---|---|

| Model | LA-500 | LA-1000 | LA-1500 | LA-2000 |

| Capacity(kg) | 500-750 | 1000-1200 | 1200-1500 | 1500-2000 |

| Crusher Power(kw) | 7.5 | 11 | 11 | 15 |

| Mixer Power(kw) | 2.2 | 3 | 4 | 4 |

| Size(m) | 2.3*1.05*2.5 | 2.4*1.3*2.9 | 2.65*1.45*3 | 2.8*1.75*3.1 |

| Weight(kg) | 230 | 320 | 380 | 430 |

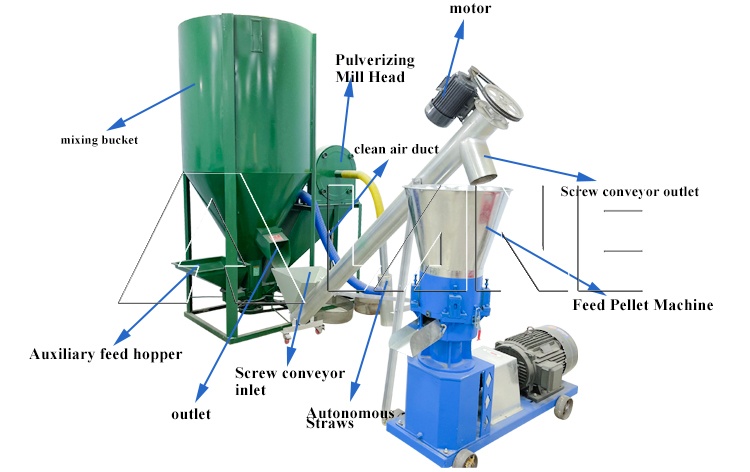

Composition structure

The feed grinding and mixing machine is mainly composed of the following parts:

Binary: used to store feed raw materials to be processed.

Crushing unit: including crushing vertical cylinder, fixed column upper strip, crushing rotating column, crushing knife and other components, crushing the raw materials through high-speed rotating hammers.

Mixing and discharging unit: including mixing drum, mixing horizontal column, discharging screw plate and stirring rod, etc., responsible for fully mixing the crushed materials and discharging them through the discharge port.

Drive system: usually driven by a motor, and the power is transmitted through a reducer to ensure the stability and reliability of the equipment operation.

Working principle

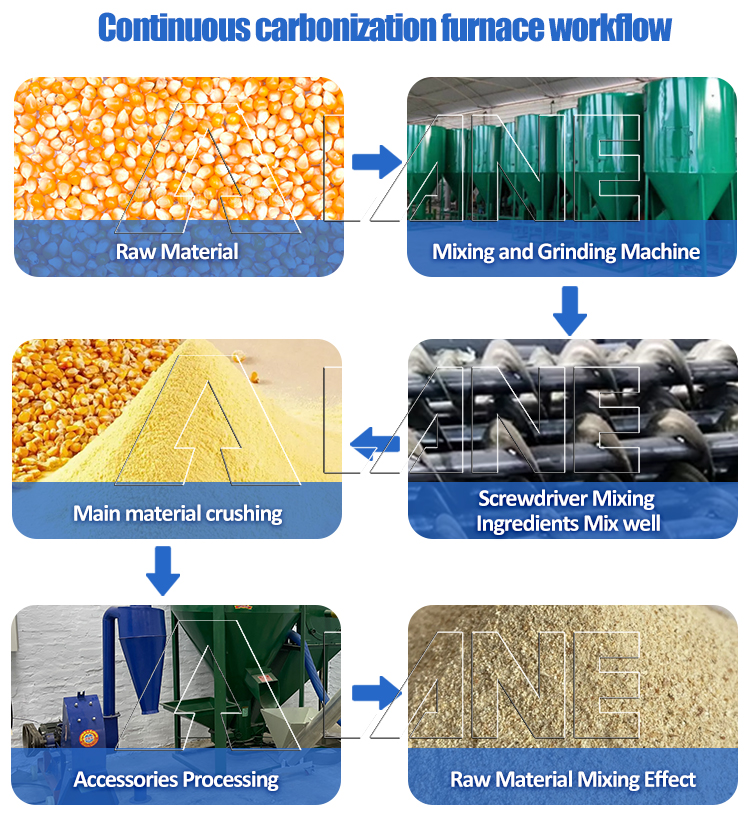

The working principle of the feed grinding and mixing machine includes two main stages:

Crushing stage: after the material enters the crushing chamber, it is crushed under the action of high-speed rotating hammers and screen plates, and then discharged from the bottom discharge port through centrifugal force and airflow.

Mixing stage: the crushed material enters the mixing unit, and the raw materials are lifted from the bottom of the barrel to the top through the rapid rotation of the spiral agitator, and then scattered back to the bottom in an umbrella-shaped fly, so as to achieve the up and down rolling and mixing of the materials in the barrel, thereby achieving a uniform mixing effect.

Outstanding advantages

The feed grinding and mixing machine has the following significant advantages:

Compact structure: The equipment occupies a small area and is suitable for use in farms with limited space.

High efficiency and energy saving: Low power consumption, and can complete the uniform mixing of a large amount of feed in a short time.

Uniform mixing: The double or multi-auger design solves the problem of uneven mixing of the traditional single auger and improves the mixing efficiency.

Strong durability: Made of wear-resistant materials, it has a long service life and low maintenance cost.

Easy operation: The equipment is easy to install and simple to operate, suitable for small and medium-sized farms and family farms.

Wide range of application: It can handle various types of feed raw materials, such as corn, sorghum, wheat, beans, etc.

The feed grinding and mixing machine has become an ideal choice for small and medium-sized farms and feed processing plants with its reasonable structure, convenient operation, high efficiency and energy saving.

As a leading fertilizer equipment supplier in China, LANE has helped more than 30,000 customers get what they need. We offer a wide range of equipment, including coating machines, granulators, mixers, tumblers, etc.In addition, we have a professional design team to help you. If you encounter any problems during the installation process or machine operation, you can always contact us.

In addition, LANE also provides flexible transportation solutions, and the products can be delivered directly to your designated place no matter where they are.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales2@lanesvc.com

Tel: +86 15515885328

Whatsapp: +86 15515885328

World-class and Energy-saving Operation, Factory Price & Fast Delivery.