Grain tower dryer is an ideal drying equipment for grain drying. It is a multi-purpose machine. It can dry rice, rapeseed, soybean, wheat, corn, peanuts and other grains on the same equipment to meet the drying needs of different grain seasons. It can be used to dry feed grain, commercial grain and seed grain, improve utilization and reduce equipment idle time. The grain tower dryer produced by LANE is very suitable for users such as grain processing plants, grain processing plants, farms, grain stations, grain growers, cooperatives, grain depots, grain and oil processing plants, etc.

Grain Tower Dryer |

|||||||

|---|---|---|---|---|---|---|---|

| Model | 5HL-60 | 5HL-100 | 5HL-120 | 5HL-150 | 5HL-200 | 5HL-300 | 5HL-500 |

| Capacity(t/d) | 60 | 100 | 120 | 150 | 200 | 300 | 500 |

| Moisture Expected Lowed Down(%) | 4-16 | ||||||

| Heated Media | Cleaning Air | ||||||

| Heated Air Temperature(°C) | <120 | ||||||

| Drying Evenness(%) | >98 | ||||||

| Broken Rate(%) | <0.5 | ||||||

| Unit Heat Consumption(kj/kg H2O) | 5800 | ||||||

| Coal Consumption(Standard)(kg/h) | 60-230 | 90-345 | 120-460 | 150-575 | 180-690 | 240-1000 | 300-1380 |

| Installation Capacity | According to tje environment,conditions,expected moisture lowed down and configuration. | ||||||

| Motor Power(kw) | 30.65 | 57.8 | 57.8 | 99.1 | 122.2 | 160.5 | 217.5 |

| Dryer Size(L*W*H) | 28*36*173M | 28*36*171M | 26*24*120M | 26*24*200M | 32*30*256M | 32*30*250M | 32*42*330M |

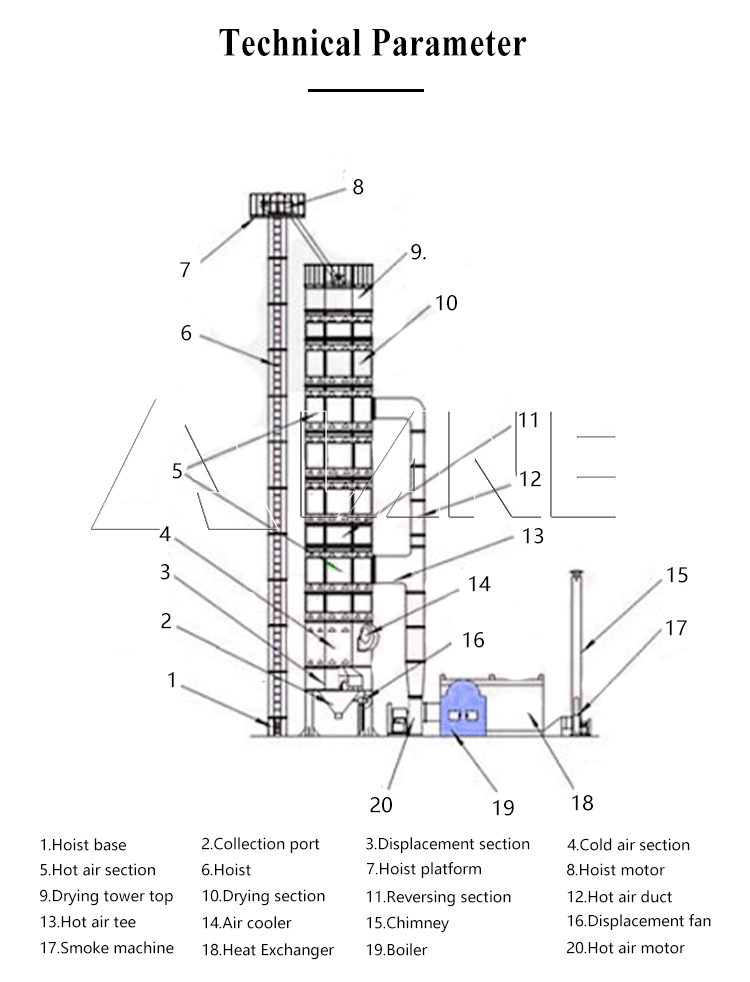

1.put grain into the grain tower dryer in batch then circulate orderly by the interaction of electric parts and structural parts.the hot air from the husk burner gets into the Mixed-flow type structure layer to across and hest the grain under thr action of two electric fans.the air flows and takes off the moisture of the grain.The exhaust gas is excluded out of the machine by the exhaust fan. when the moisture reaching to the set value,the machine stops working.

2.The hot blast stove equipped with the grain tower dryer is an energy-saving and environment-friendly hot blast stove. The hot blast stove supplies heat to indirectly dry the grain. During the drying process, the grain continuously circulates and the grain rubs against each other. The awns, velvet hair, etc. on the surface of the grain are removed, and the dust is removed from the machine to improve the cleanliness of the dried grain. The production cost of this grain dryer is low. The supporting drying oven can use coal, electricity, natural gas and such as rice husk, corn broken shaft, wood foot and so on as dry heat source, dry Low cost, energy saving and environmental protection.

For more information, please contact us by sending an inquiry today! We can help you!

1. Temperature control: Excessive temperature may damage the nutritional content ofgrains, sothe drying temperature needs to be adiusted according to the type of grain.

2. Ventilation: Good ventilation helps to dry evenly and avoid local overheating or uneven drying.

3. Regular maintenance: Keep the equipment clean and in good condition, and check the heat souree and fan regularly.

1.lmprove the storage stability of grain.

2.Reduce mildew and pests.

3. Can handle large quantities of grain and improve production efficiency.

World-class and Energy-saving Operation, Factory Price & Fast Delivery.