Turkey is a unique bridge between Europe and Asia. Its agricultural sector is huge, producing everything from hazelnuts to grains. For many years, we have watched Turkey modernize its farming techniques. Today, Turkish farmers are moving away from traditional powders and toward granules. Why? Because granules are easier to spread, don’t blow away in the wind, and release nutrients slowly into the soil.

Currently, the Turkish government is pushing for more local production to reduce imports. This creates a perfect window for investors. By setting up a local granular fertilizer production line, you can provide fresh, specialized formulas for local crops like olives, cotton, and greenhouse vegetables. Our company has spent over 20 years focusing on the Chinese fertilizer machinery field. We have seen how local production transforms regional economies, and we bring that deep industry experience to every project we touch in Turkey.

Building a full granular fertilizer production line involves several key stages. Each piece of equipment must work perfectly with the next to ensure high quality. When we design a system for our clients, we look at the specific local raw materials available in Turkey—such as sheep manure from Central Anatolia or mineral deposits near the coast.

The first step in any granular fertilizer production line is getting the materials ready. You cannot make a good granule from chunky, uneven waste.

Because we have a professional engineering team, we don’t just sell you a machine. We design the mixing setup based on your specific formula. We provide customized services to make sure the equipment fits your factory space and your production goals perfectly.

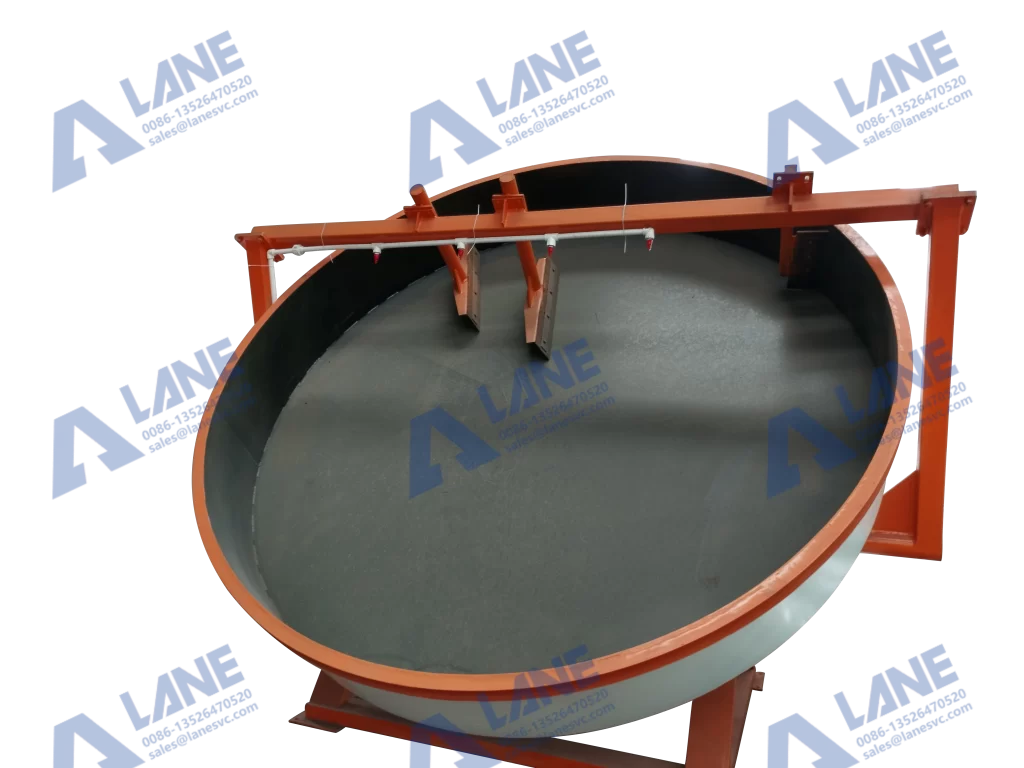

This is the “heart” of the granular fertilizer production line. This stage turns the blended powder into solid, round pellets.

Our equipment is built to meet ISO9001 and CE international quality standards, ensuring that your granulation process is safe, efficient, and produces a consistent product that Turkish farmers will trust.

Freshly made granules are damp and soft. If you bag them immediately, they will turn back into a big lump of mud.

No granular fertilizer production line is perfect; some granules will be too big, and some will be too small.

To make your product look professional and prevent it from sticking together in a humid warehouse in Izmir or Antalya, you need a coating.

Setting up a granular fertilizer production line in a foreign market like Turkey can feel complicated. That is why we offer an all-in-one, full-scale service. We don’t just ship boxes; we stay with you from the moment you plan your factory layout to the day you start selling your first bag of fertilizer.

Our team travels directly to your site to handle the installation of the entire production line. We believe that a machine is only as good as the person running it, so we also provide detailed training for your local staff. If something goes wrong later, our after-sales support covers everything from remote troubleshooting to sending engineers for maintenance. We want your production line to run smoothly for decades.

We specialize in providing machinery for organic, compound, and even liquid fertilizers. This variety is important in Turkey, where soil types change every few hundred kilometers. Whether you are processing chicken manure or chemical NPK, we have the specialized experience to make it work.

The trend in Turkey for 2026 is “Green and Efficient.” The government is offering incentives for “Organo-mineral” fertilizers—a mix of organic matter and chemical nutrients. Our granular fertilizer production line is flexible enough to handle these complex blends.

By choosing to build your line now, you are tapping into a market that is hungry for innovation. Turkey’s strategic location also allows you to export your finished granules to neighboring countries in the Middle East and Eastern Europe very easily. With our 20+ years of experience and ISO9001/CE certified equipment, you are not just buying a machine; you are building a future.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520