Granular organic fertilizer production line technology is revolutionizing agriculture, transforming organic waste into high-value, nutrient-rich granular fertilizer. These lines not only help reduce environmental pollution but also support sustainable agricultural practices. LANE designs and manufactures complete fertilizer production solutions, combining high-performance machines, customized configurations, and professional after-sales support to help farmers and agricultural businesses around the world efficiently produce high-quality granular organic fertilizer.

Granular organic fertilizers are made from decomposed organic matter, such as animal manure, crop residues, and other biodegradable waste. Unlike powdered fertilizers, granular fertilizers are easier to store, transport, and apply.

The quality of raw materials directly determines the quality of the final fertilizer product. Common raw materials for granular organic fertilizer production lines include:

|

Category |

Examples |

|

Animal Manure |

Chicken manure, cow dung, pig manure, goat manure |

|

Agricultural Waste |

Rice husk, straw, corn stalks, peanut shells |

|

Food Industry Waste |

Fruit and vegetable scraps, sugar mill waste, brewery waste |

| Green Waste |

Grass clippings, garden waste, tree leaves |

| Biodegradable By-products | Mushroom substrate, sawdust, bio-slurry from biogas plants |

LANE Tip: Using a mix of animal manure and crop residues provides a balanced nutrient profile for crops while improving granule formation during production.

A granular organic fertilizer production line is more than just a set of machines; it’s a carefully coordinated process, each stage of which transforms raw waste into high-quality, ready-to-sell granules. Let’s take a closer look at each step.

1.Awakening the Raw Materials – Fermentation & Composting

Everything begins with transforming raw organic matter — such as animal manure, crop residues, and green waste — into a stable, mature compost. This stage is crucial because:

It eliminates harmful bacteria and weed seeds.

It stabilizes nutrients for plant availability.

LANE’s crawler type compost turners aerate the piles evenly, control temperature efficiently, and shorten composting time from months to as little as 7–15 days.

2.Breaking Barriers – Crushing & Pre-Screening

After fermentation, compost may contain lumps, fibrous material, or undecomposed debris. The crushing process breaks these materials down into fine particles, creating an ideal particle structure for pelleting. LANE’s high-efficiency vertical shaft crushers ensure uniform particle size, while pre-screeners remove oversized debris that could affect pellet quality.

3.The Heartbeat of the Line – Granulation

This is where the magic happens — fine compost particles are shaped into dense, uniform granules. Granulation improves the product’s usability, appearance, and market value.

3.1 Granulation Methods

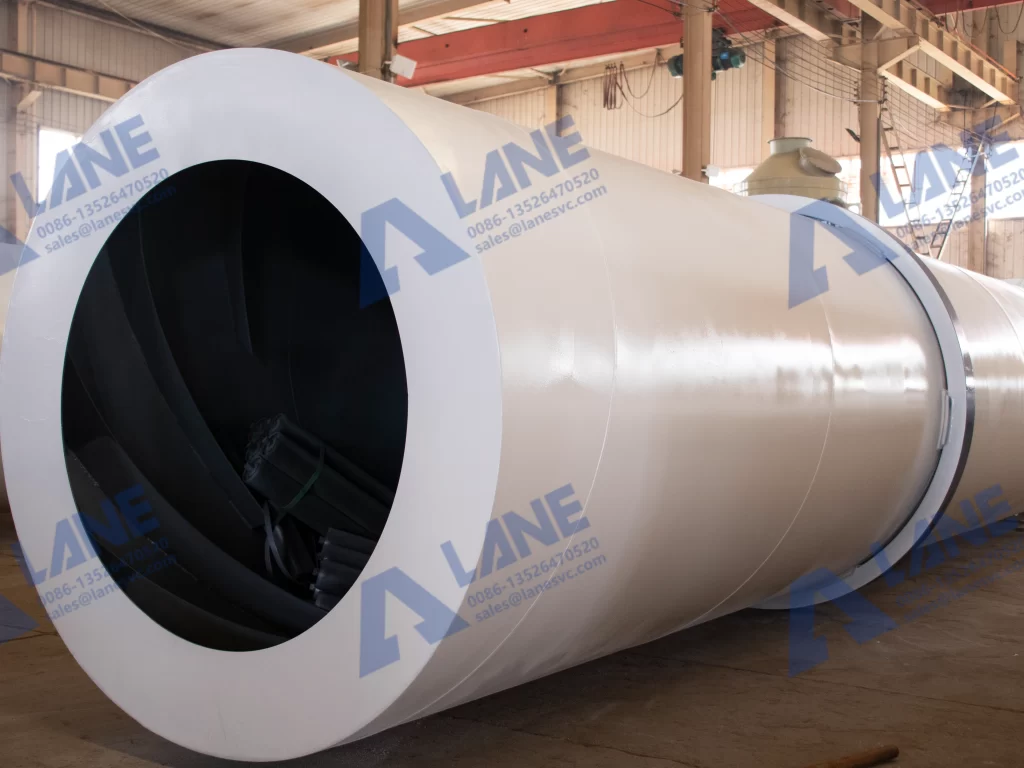

Rotary Drum Granulator – Uses a rotating cylinder to tumble material, with moisture and binders forming granules gradually. Best for large-scale continuous production.

Disc Granulator – Uses a tilted rotating disc to roll material into granules, ideal for small to medium capacity with excellent control over granule size.

New Type Organic Fertilizer Granulator – Employs a high-speed stirring rotor for high shaping rate, suitable for pure organic materials.

3.2 Why LANE Granulators Stand Out

High Shaping Rate – Over 90% qualified granules in one pass.

Moisture Control – Optimized for wet granulation, handling moisture levels between 25–30%.

Adjustable Granule Size – Output size from 3–8 mm to meet market demand.

Durable Construction – Anti-corrosion steel ensures long service life, even with acidic materials.

Energy Efficiency – Lower power consumption per ton compared to conventional granulators.

3.3 LANE Granulation Advantage

LANE doesn’t just sell machines — we engineer the entire granulation stage to integrate perfectly with upstream and downstream processes, ensuring maximum efficiency and consistent granule quality.

4.Locking in Quality – Drying & Cooling

Fresh granules contain excessive moisture, which can lead to clumping or microbial growth during storage. Drying reduces the moisture content to 10-15%, while cooling protects the granule structure and prepares it for coating. LANE’s rotary drum dryers and coolers are energy-optimized to maintain granule integrity and avoid overdrying.

5.Final Touches—Polishing and Coating

A polishing machine shapes and evens out the granules, while a thin layer of powder or liquid coating prevents clumping, enhances the product’s appearance, and adds additional nutrients or beneficial microorganisms. This step can truly make your product stand out on store shelves.

6.Market Preparation – Automated Packaging

Finally, the pellets are weighed, bagged, and sealed. LANE’s automatic packaging machines ensure precise filling, reduce labor costs, and increase packaging speed, preparing them for shipment to farms, distributors, and retail stores.

Every fertilizer producer has unique raw materials, production goals, and market demands. Therefore, LANE not only provides standard equipment, but we also design customized granular organic fertilizer production line solutions to perfectly meet your business needs.

1.Capacity Ranges for Every Scale

Small-Scale Lines (1–3 TPH) – Ideal for local organic farms, cooperatives, and pilot projects.

Medium-Scale Lines (5–10 TPH) – Suitable for regional fertilizer suppliers targeting stable production volumes.

Large-Scale Lines (15–20+ TPH) – Designed for industrial fertilizer plants serving domestic and export markets.

Whether you’re producing a few tons per day or hundreds of tons per week, LANE can design a production line that grows with your business.

2.Raw Material-Specific Configurations

Different raw materials require different processing approaches. LANE engineers design production lines based on your primary input materials:

Manure-Based – Chicken, cow, pig, goat manure.

Crop Residue-Based – Straw, corn stalks, rice husks.

Mixed Organic Waste – Combining manure, plant residues, and food industry waste.

Specialty Inputs – Mushroom substrate, biogas slurry, green waste.

This ensures maximum nutrient retention and optimal granule formation.

3.Flexible Granule Size Control

Market demands vary — some crops and distributors prefer 2–5 mm granules for uniform application, while others prefer 6–8 mm granules for slow-release performance.

LANE’s adjustable granulators give you complete control over output size, allowing you to produce multiple product types from the same production line.

4.Automation Levels That Match Your Workforce

Semi-Automatic – Lower investment, requires moderate labor input.

Fully Automatic – High efficiency, minimal labor, real-time process monitoring.

Our fully automated granular organic fertilizer production line integrates intelligent controls, allowing one operator to manage the entire process from a central panel.

5.Plant Layout & Space Optimization

LANE designs equipment layout based on:

Available land area

Material flow optimization

Safety and maintenance accessibility

Future expansion potential

From compact indoor setups to sprawling industrial facilities, LANE ensures maximum production efficiency within your available space.

LANE’s customization philosophy is simple: Your production line should work for your business, not the other way around.LANE combines engineering expertise, manufacturing precision, and market insight to deliver efficient, scalable, and durable granular organic fertilizer production lines.

As agriculture evolves towards more sustainable models, demand for granular organic fertilizer production lines is rapidly growing. Farmers and agricultural companies are seeking efficient ways to convert organic waste into high-value fertilizer products, and granular fertilizers are becoming a preferred choice in the global market.

The global organic fertilizer market is projected to exceed $10 billion in 2024 and is expected to grow at an annual rate of 8-10% through 2030. Government incentives, consumer demand for chemical-free foods, and soil remediation are driving this growth. This presents a significant opportunity for manufacturers to invest in advanced production technologies.

Granular organic fertilizers offer competitive advantages over powdered fertilizers. They are easier to apply, work well with mechanical spreaders, exhibit lower nutrient losses, and offer extended storage stability. Consequently, an increasing number of fertilizer manufacturers are upgrading their equipment to granular organic fertilizer production lines.

Both the domestic and export markets show strong potential. Many regions still import organic fertilizers, creating opportunities for local producers. Meanwhile, granular fertilizer imports are rapidly growing in emerging markets such as Southeast Asia, Africa, and South America. Manufacturers who establish themselves early can gain long-term market share and brand recognition.

By investing in a granular organic fertilizer production line now, your business can position itself for continued growth. With tailored solutions, modern automation systems, and market-focused design, LANE helps customers seize these opportunities and remain competitive in the global organic fertilizer industry.

Q1: What is the ideal moisture content for pelleting?

A: Generally, the optimal moisture content for wet pelleting is 25-30%.

Q2: Can I use crop residues alone without manure?

A: Yes, but the nutrient content may be reduced. Mixing with manure can improve the fertilizer’s quality.

Q3: How long does a complete production cycle take?

A: From fermentation to packaging, it takes approximately 15-30 days, depending on the materials and process.

Q4: Do the pellets need to be dried before packaging?

A: Yes, drying extends shelf life and prevents clumping during storage.

Q5: What is the service life of LANE equipment?

A: With proper maintenance, most machines can provide reliable operation for 8-12 years. And with our 5-year warranty, you can be sure of our quality.

A granular organic fertilizer production line is a vital investment in sustainable agriculture. It transforms organic waste into a marketable, environmentally friendly product, improves soil fertility, and meets growing consumer demand for safe, chemical-free food. With LANE’s advanced technology, global services, and customized solutions, you can build a competitive fertilizer production business that delivers consistent quality and profitability.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520