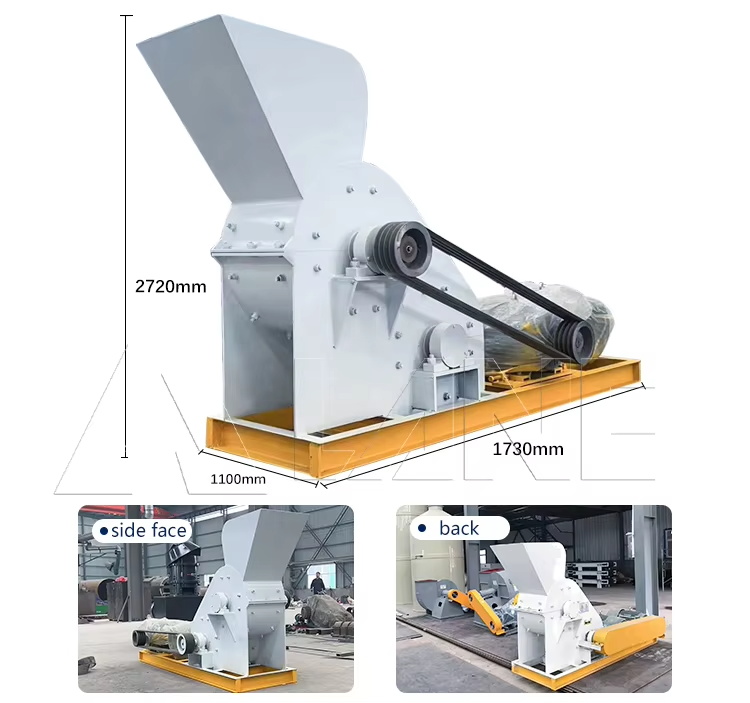

Hammer crusher is a device that uses a high-speed rotating hammer head to exert strong impact on materials and achieve crushing. It has a simple structure and easy maintenance, and is widely used in various industries.LANE can customize a crusher for you to meet any of your needs.

Hammer crusher |

||||||

|---|---|---|---|---|---|---|

| Model | Capacity(tph) | Power(kw) | Overall Size(mm) | Number Of Hammers | Hammer Weight(kg) | Weight(t) |

| LACD-400*400 | 45422 | 7.5+7.5 | 2200*900*1200 | 24 | 2.5 | 0.6 |

| LACD-600*400 | 45580 | 18.5+18.5 | 2600*950*1500 | 24 | 3.5 | 1 |

| LACD-600*600 | 15-20 | 22+22 | 2600*1170*1500 | 40 | 3.5 | 1.3 |

| LACD-600*800 | 20-30 | 30+22 | 2800*1350*1700 | 48 | 3.5 | 1.8 |

| LACD-800*600 | 30-40 | 45+37 | 3200*1250*2000 | 40 | 8 | 3 |

| LACD-800*800 | 40-50 | 55+45 | 3200*1400*2000 | 48 | 8 | 3.5 |

| LACD-1000*800 | 50-60 | 55+75 | 3950*1750*2280 | 48 | 10 | 5.5 |

| LACD-1000*1000 | 60-90 | 90+75 | 4000*1900*2400 | 52 | 10 | 7 |

The material enters the hammer crusher through the feed port. The feed port is usually conical to ensure that the material can enter the crushing chamber smoothly.

The motor drives the material to rotate at high speed through a transmission device (such as a belt, elastic coupling, etc.). When the material enters the crushing chamber, the high-speed rotating hammer head hits and impacts the material strongly, causing the material to be crushed along the natural cracks, joints and other fragile parts.

The initially crushed material continues to be continuously hit by the hammer head in the crushing chamber, and the materials will also collide with each other, further promoting the crushing process.

The crushed material is screened through the screen plate. The material size smaller than the size is discharged through the screen plate; while the coarse particle size larger than the size remains on the screen plate, continues to hit and grind, and can only be discharged from the machine through the screen plate after being crushed to the required particle size.

If you have a better idea, or would like to do an experimental test as well, please contact us right away!

Simple structure

The design of a hammer crusher is relatively simple, mainly composed of components such as a box, rotor, and hammer head. This structure simplifies the manufacturing and maintenance process of the equipment, enabling the hammer crusher to be quickly put into use in various industrial applications.

Efficient crushing capability

The hammer crusher uses a high-speed rotating hammer head to impact and crush materials, with high crushing efficiency and the ability to handle large amounts of material input. For example, a large single-stage hammer crusher can directly crush limestone with a diameter of 1 meter to about 20mm.

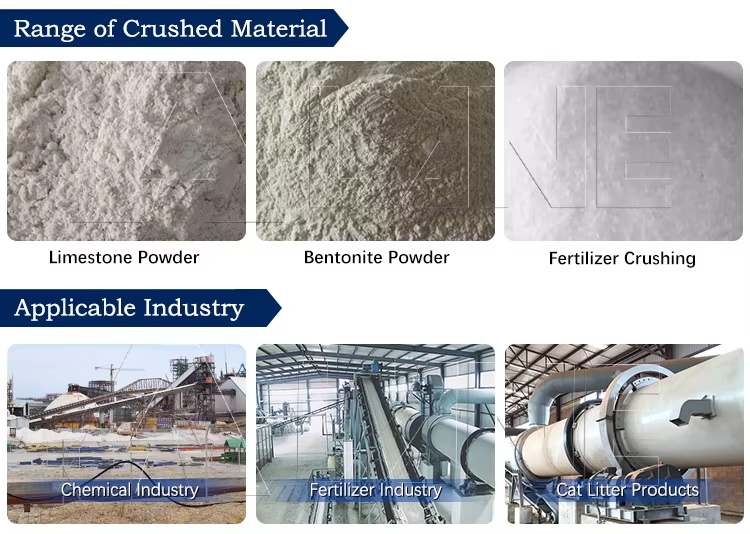

Wide range of applications

This device is not only suitable for crushing materials with medium hardness, but also for processing materials with high humidity. It has a wide range of applications and can easily handle materials from limestone to coal.

World-class and Energy-saving Operation, Factory Price & Fast Delivery.