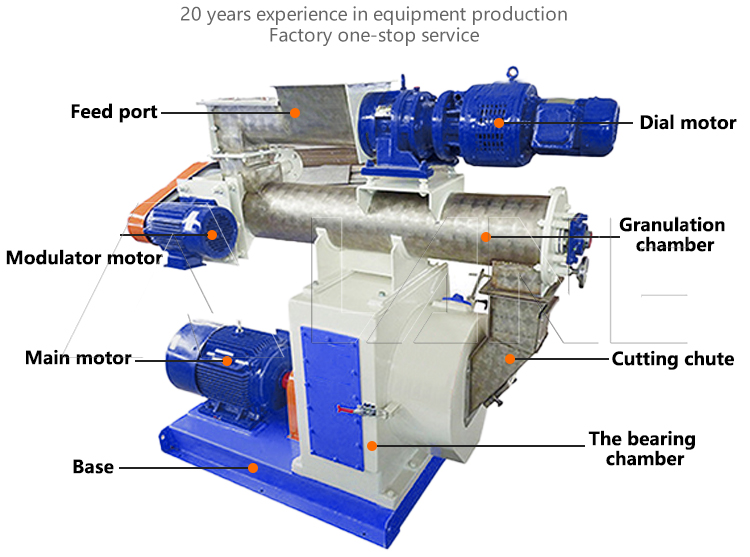

Horizontal ring die pellet machine is a kind of equipment for producing pellet fuel. It can process many kinds of raw materials such as pine, birch, poplar, fruit wood, wood chips and crop straw into pellets, which can be used in fireplaces, boilers and biomass power plants.

Horizontal Ring Die Pellet Machine |

||||

|---|---|---|---|---|

| Model | Host power (kW) | Feeder power (kW) | Conditioner power (kW) | Output (t/h) |

| LA-HPM2 | 22 | 1.5 | 2.2 | 0.5-1.5 |

| LA-HP3 | 30/37 | 1.5 | 2.2 | 1-3 |

| LA-HPM4 | 37 | 1.5 | 2.2 | 2-4 |

| LA-HPM6 | 55 | 1.5 | 3 | 3-6 |

| LA-HPM8 | 75/90 | 2.2 | 3 | 7-10 |

| LA-HPM10 | 110 | 2.2 | 3 | 10-15 |

The operation of the horizontal ring die pellet machine is based on a special mechanical process, in which the ring die is active and the pressure roller is passive. When the powdered material enters the pre-compression zone between the rotating ring die and the fixed pressure roller, the material has a certain degree of looseness, and pores of varying sizes are formed inside, and at the same time it will be driven and squeezed by the rotating die.

The powdered particles move (sliding and rolling) to reduce the space between them, and the internal pressure and material density will also increase accordingly, and the powdered materials will change from point contact to surface contact.

When the pressure reaches a certain value, the material with higher density enters the extrusion zone from the pre-compression zone, changes from elastic deformation to plastic deformation and flows into the die hole. The interaction between the particles will generate adhesion, resulting in the material being held in the die hole for a certain period of time. The particles that reach the predetermined density and strength are squeezed out of the die hole and cut by the cutter to form particles of the required length.

The all-stainless steel feeder, configured with original imported frequency converter to control feeding uniformly and accurately.

Monitoring system is equipped, solving the problem of high temperature hazard in the pelleting chamber caused by the improper operation thus efficiently avoiding the danger of bursting and fire.

The components is made by international advanced manufacturing craft and designed according to the characteristics of the material from the customers, prolonging the service time of the equipment.

The ring die of feed machine with quick-release coupling reduces the time of replacing the ring die and improves the production efficiency.

Double-motor drive. The high strength SPB narrow V-belt drive transmit with stability and reliability but with low noise.

The horizontal ring die pelleting mill is configured with many kinds of ring dies with different aperture diameters and compression ratio, the customers can choose according to their needs.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales2@lanesvc.com

Contact number: +86 15515885328

Whatsapp: +86 15515885328

World-class and Energy-saving Operation, Factory Price & Fast Delivery.