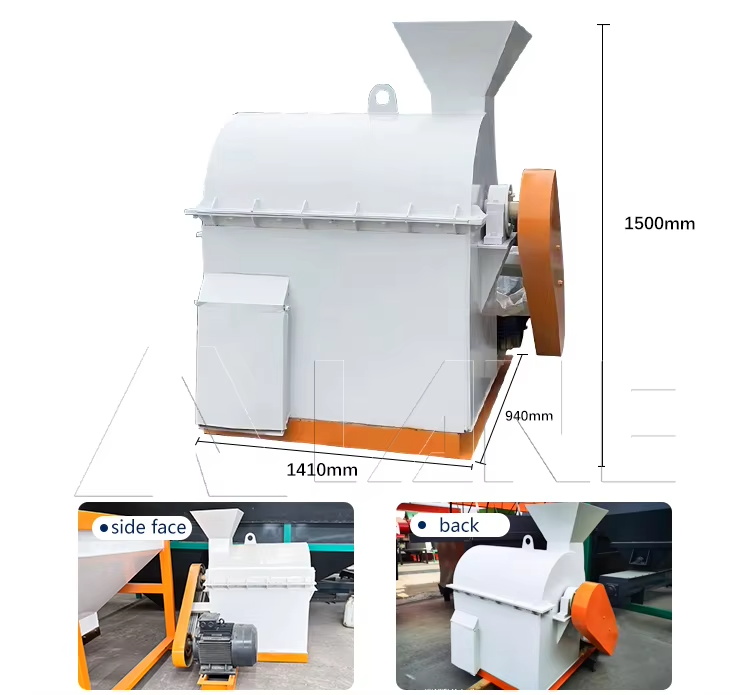

The Horizontal Semi-Wet Material Crusher is designed for crushing organic materials with high moisture content, such as manure, sludge, and compost. It efficiently breaks down larger particles into smaller, uniform sizes, ensuring smoother processing for subsequent stages of production. With its robust design and durable components, this crusher minimizes clogging and maximizes output, making it an essential part of organic fertilizer production lines. This type of equipment usually adopts a horizontal structure and has a strong adaptability to the moisture content of the material. LANE can customize a dedicated horizontal semi-wet material crusher for you to meet any of your needs.

Horizontal semi-wet material crusher |

|||||

|---|---|---|---|---|---|

| Model | Capacity(tph) | Power(kw) | Overall Size(mm) | Input Size(mm) | Output Size(mm) |

| LAC-60H | 45326 | 30 | 1390*1290*1310 | 400*600 | 300*450 |

| LAC-80H | 3-6 | 30 | 1610*1400*1510 | 400*600 | 300*450 |

| LAC-90H | 4-8 | 37 | 1610*1400*1710 | 400*600 | 400*450 |

The material enters the horizontal semi-wet material crusher through the feed hopper. Under the impact of the high-speed rotating hammer and the friction of the screen plate, the material is gradually crushed to form fine particles.

Then it is transported to the lower rotor for further crushing. Under the repeated impact of the pendulum, grinding disc and blades, the material forms a high-speed impact, high-frequency vibration and compact material state.

Driven by the air flow, the crushed material moves along the outer edge and is continuously hit, collided and rubbed by the hammer, tooth plate and screen, so that it is quickly crushed.

When the material particle size is smaller than the diameter of the screen hole, it quickly passes through the screen hole and comes out of the screen under the centrifugal force of the rotor and falls into the discharge port below. The coarse material continues to stay in the crushing chamber for further crushing.

By replacing the screen with different mesh sizes, the particle size of the final product can be controlled.

If you have a better idea, or would like to do an experimental test as well, please contact us right away!

The horizontal semi-wet material crusher for organic fertilizer production is one of the most essential machines in modern fertilizer manufacturing. Designed to handle high-moisture materials without clogging, it delivers reliable crushing performance while reducing downtime and operational costs.

The semi-wet crusher for organic fertilizer production easily handles raw materials with 40–60% moisture content, eliminating the need for pre-drying and significantly saving both energy and production time.

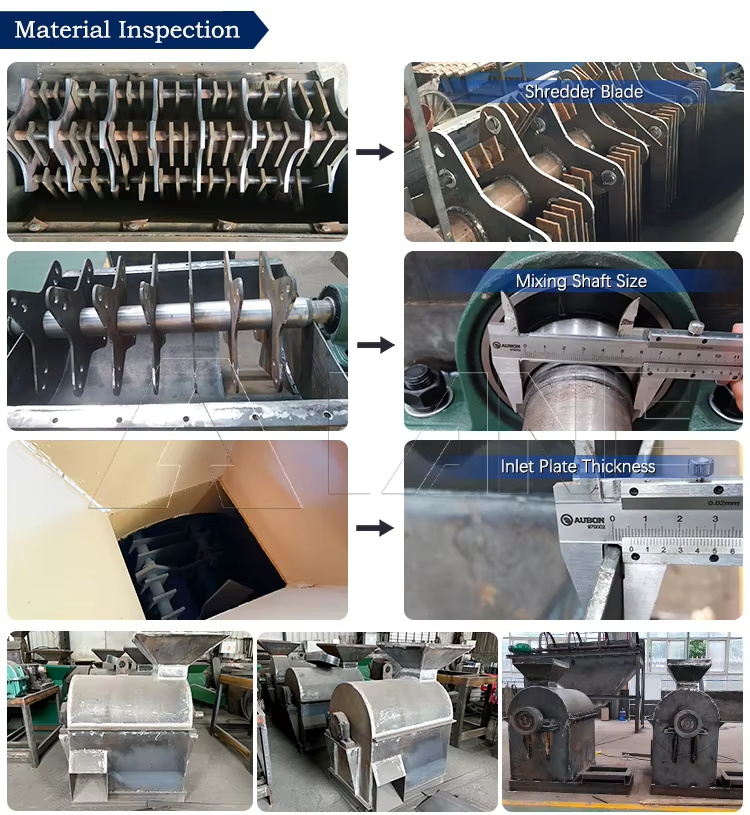

Its specially designed blade arrangement ensures a consistent particle size, which greatly improves granulation efficiency and optimizes fermentation, leading to higher fertilizer quality and stronger market competitiveness.

Equipped with double-layer alloy steel or stainless steel blades, the horizontal semi-wet material crusher offers excellent resistance to wear and corrosion, extending the service life to 6–12 months depending on material type and usage frequency.

The simplified structure allows for quick blade replacement and requires minimal lubrication, which reduces downtime and keeps production efficiency consistently high.

It is suitable for processing poultry manure, livestock manure, compost, crop residues, sludge cake, and returned granules, and integrates seamlessly into both organic and compound fertilizer production lines.

Available in a range of capacities from 1–20 t/h, the crusher also features adjustable output size settings to meet different production requirements with ease.

Its heavy-duty construction, combined with an enhanced bearing and shaft design, ensures stable, continuous operation even under demanding industrial conditions.

In short, the horizontal semi-wet material crusher for organic fertilizer production is a powerful, reliable, and versatile solution for any fertilizer plant seeking higher efficiency, consistent product quality, and reduced operating costs.

Semi-wet material crusher is used for biological organic compost fermentation, the urban domestic waste composting, grass mud carbon, rural garbage, industrial organic waste of straw, breeding livestock and poultry manure and other biological fermentation high wet material crushing.

World-class and Energy-saving Operation, Factory Price & Fast Delivery.