The Hot Blast Stove Machine uses fuel to burn directly, and after high purification treatment, it forms hot air, which is directly in contact with the material for heating, drying or baking. In many industries, it has become a replacement product for electric heat sources and traditional steam power heat sources.

LANE can customize a dedicated Hot Blast Stove Machine for you to meet any of your needs.

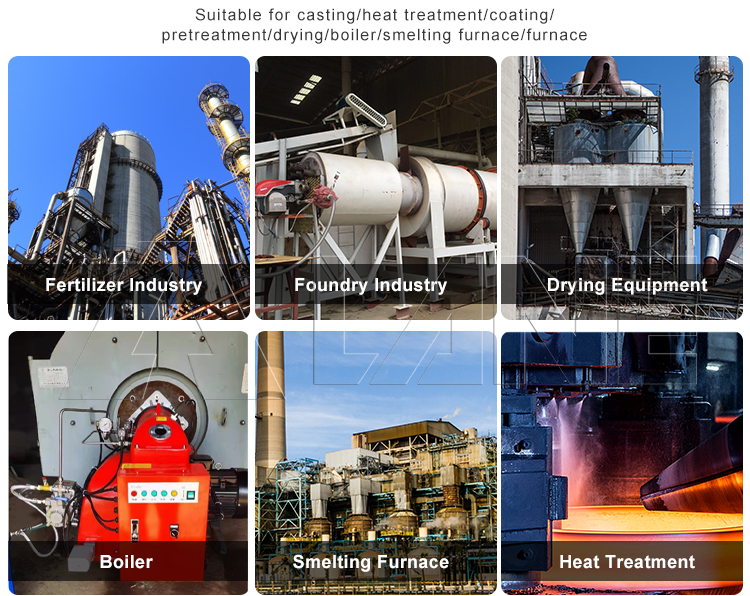

The hot air furnace is a heat treatment equipment, mainly used for fertilizer drying and baking. Its working principle is to heat and dry the fertilizer by burning the heat and hot air generated by the fuel.

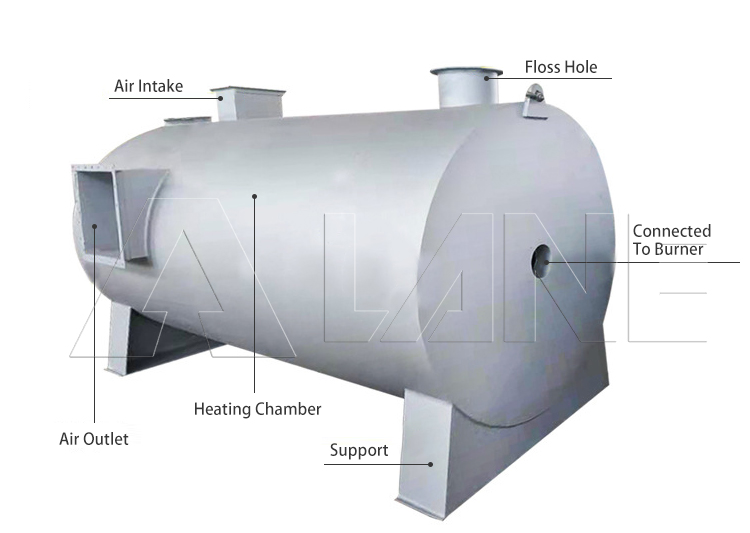

Specifically, the hot air furnace consists of a combustion chamber, a heat exchanger, a fan and a conveying device. The fuel burns in the combustion chamber, generating high-temperature flue gas that passes through the heat exchanger and transfers the heat to the hot air used for drying.

The hot air is sent to the material feeding area by the fan to heat and dry the material, and then sent out of the hot air furnace. During the whole process, the flue gas is discharged from the hot air furnace and discharged into the atmosphere after being treated by the dust removal equipment.

The working principle of the hot air furnace is simple and easy to operate. It is widely used in fertilizer, chemical fertilizer, pesticide and other industries.

For more information, please contact us by sending an inquiry today! We can help you!

World-class and Energy-saving Operation, Factory Price & Fast Delivery.