Understanding how fertilizers are manufactured is of vital importance for anyone engaged in modern or sustainable agriculture. Fertilizers play a crucial role in enhancing soil fertility and increasing crop yields. However, not all fertilizer production methods are the same. In recent years, organic fertilizer production lines have become one of the most effective and environmentally friendly systems for converting organic waste into the nutrients needed by plants.

The Process of How Fertilizers Are Manufactured

The process of how fertilizers are manufactured begins with the selection and preparation of raw materials. In the case of organic fertilizers, these materials often include livestock manure, agricultural residues, food waste, and other biodegradable substances. These ingredients are rich in organic matter and nutrients such as nitrogen, phosphorus, and potassium — the core elements needed for healthy plant growth.

Once the raw materials are collected, they are fed into the organic fertilizer production line where they undergo several stages of processing. The first step is fermentation or composting, which uses aerobic microorganisms to decompose the organic matter. During this phase, the composting temperature naturally rises, killing pathogens, weed seeds, and harmful bacteria. This step is crucial in explaining how fertilizers are manufactured safely and biologically.

After fermentation, the material is crushed and finely mixed to ensure a uniform texture. This mixture then moves to the granulation process, a key part of the organic fertilizer production line. Different granulation machines, such as the double roller granulator, rotary drum granulator, or stirring pin granulator, can be used depending on the raw material type and desired particle size. The goal is to create round, dense granules that are easy to store, transport, and apply in the field.

Once granulated, the product goes through drying and cooling to remove excess moisture, followed by screening to separate qualified granules from oversized or undersized ones. The final step in how fertilizers are manufactured is automatic packaging, where the finished organic fertilizer is bagged and ready for distribution.

Compared with chemical fertilizers, the organic fertilizer production line offers several advantages. It recycles waste resources, reduces pollution, and improves soil structure and microbial activity. The organic fertilizer not only provides nutrients but also enhances soil health in the long term, making it a sustainable solution for modern agriculture.

In summary, how fertilizers are manufactured in an organic fertilizer production line involves a complete transformation — from waste to wealth. Through scientific fermentation, granulation, and precise processing, organic fertilizers become a key force in building a green and circular agricultural economy. As more farmers and producers adopt this technology, the world moves one step closer to sustainable and eco-friendly food production.

LANE Advantages in Fertilizer Production

When discussing how fertilizers are manufactured, equipment quality and process design are critical factors that determine efficiency and final product quality. This is where LANE stands out.As a professional manufacturer of organic fertilizer production lines, LANE provides integrated solutions from composting to granulation.

Our systems are designed with:

High Precision & Reliability – Each compost turner, crusher, mixer, and granulator is engineered for stable performance and long service life.

Energy Efficiency – Advanced design reduces power consumption and simplifies maintenance.

Customized Solutions – Every production line is tailored to local raw materials, capacity needs, and climate conditions.

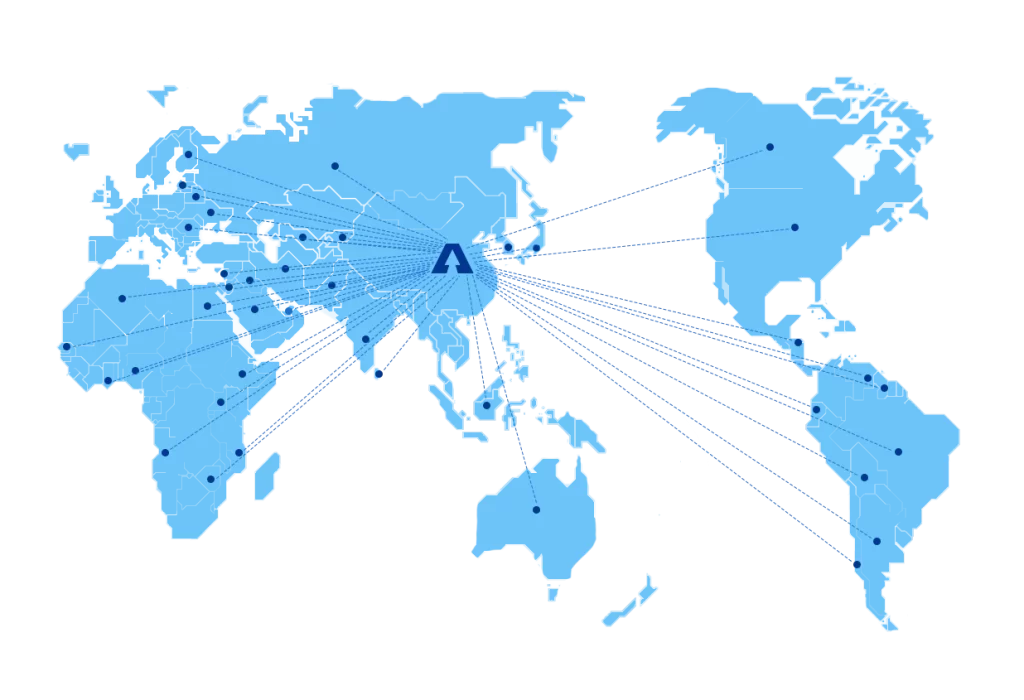

Global Support – From project consultation and layout design to installation and after-sales service, LANE ensures smooth operation worldwide.

With years of manufacturing experience, LANE is not only a machine supplier but also a trusted partner helping customers truly understand how fertilizers are manufactured efficiently and sustainably. Our goal is to turn organic waste into valuable fertilizer — creating a greener and more profitable future for agriculture.

Conclusion

If you are planning to start an organic fertilizer business or upgrade your existing facility, investing in a professional organic fertilizer production line can greatly improve efficiency and product quality.

Our systems are designed for different capacities and raw materials, helping you understand not only how fertilizers are manufactured, but also how to make your production more sustainable and profitable.

Contact us today to get a customized solution for your fertilizer production needs — from composting to granulation, we’re here to support your green agriculture journey.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520