As mushroom production continues to grow around the world, farms and factories are working hard to find better ways to handle mushrooms from start to finish. Mushrooms are soft, easy to damage, and very sensitive to temperature and moisture. Because of this, each step of processing must be done carefully to keep them fresh and safe for consumers. Many producers now rely on simple, easy-to-use machines that work together to speed up the process and reduce unnecessary waste. When machines are linked in a smooth line, workers can focus on important tasks instead of repeating tiring manual work. This is why many businesses value Integrated equipment enhancing mushroom processing efficiency, as it helps maintain quality, protect mushrooms during handling, and support higher daily output.

Before mushrooms can be harvested, the raw materials used to grow them must be properly prepared. This material—often made from straw, plant fibers, manure, or recycled farm waste—needs to break down so mushrooms can absorb nutrients easily. Fermentation tanks offer a simple and clean way to help this process. Inside a fermentation tank, the material warms up naturally, becomes softer, and changes into a richer form that mushrooms can use. Workers can easily check the temperature, add water if needed, and make adjustments without much effort. Mushrooms grow better when the starting material is well-prepared, making fermentation tanks an important tool for farms that want consistent results. Their role clearly supports Integrated equipment enhancing mushroom processing efficiency, especially during the early stages before mushroom growth even begins.

While fermentation tanks are helpful for closed, controlled processing, many larger mushroom farms prepare their growing material outdoors in long piles. These piles need plenty of air, or else they may become too hot or start to smell unpleasant, which is not good for growing mushrooms. Windrow turners solve this problem by lifting and flipping the pile from one side to the other. Each time the pile is turned, fresh air enters and helps the material break down more evenly. This also keeps moisture from becoming trapped and reduces the chance of unwanted bacteria forming. Since mushrooms rely on clean, healthy substrate, windrow turners help ensure a good foundation for the entire production line. When used together with fermentation tanks, they show how Integrated equipment enhancing mushroom processing efficiency can support both small and large farms through simple, reliable tools.

Vertical-crusher, though simple, play an important role in preparing both mushrooms and raw materials for later processing. When mushrooms are turned into powder, snacks, or seasoning mixes, they must first be broken into smaller pieces. Crushing machines make this job quick and easy, saving workers many hours of manual cutting. These machines are also useful for breaking down straw or other plant materials used as mushroom substrate. The finer the material, the easier it is to mix, ferment, and spread for mushroom growth. Because mushrooms grow best in soft, even material, crushing machines help build a more comfortable growing environment. By making raw materials easier to handle, crushing machines support Integrated equipment enhancing mushroom processing efficiency, improving both the early and late stages of mushroom production.

Screening machines help separate materials by size, which is important for keeping mushroom substrate clean and uniform. When preparing substrate, workers use screens to remove large pieces that may block air or hold too much moisture. This prevents problems during mushroom growth, such as slow development or uneven results. Screening machines are also used after mushrooms are processed. For example, mushroom powder must be smooth and even, without big chunks. By shaking or rolling materials through different-sized screens, workers can quickly sort everything without needing to check by hand. A cleaner substrate leads to healthier mushrooms, while cleaner powder leads to better mushroom products for customers. This important role in sorting highlights how Integrated equipment enhancing mushroom processing efficiency helps every stage stay consistent and dependable.

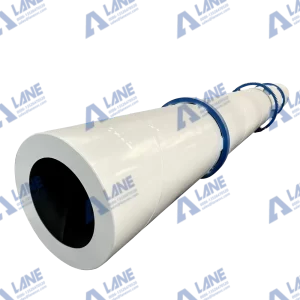

Stirring pin granulators are useful when mushroom materials need to be turned into small, round pellets. For example, dried mushroom powder can be made into pellets for cooking or health products. Leftover mushroom substrate can also be turned into pellets and reused as organic fertilizer. Pellets are easy to move, pack, and store, which helps reduce waste and saves space. Granulators press soft materials into firm shapes, making them stable and longer-lasting. The ability to turn loose or powdery material into something more solid adds value and makes both mushrooms and their by-products more useful. This process is a clear example of how Integrated equipment enhancing mushroom processing efficiency turns simple materials into higher-value products without complicated steps.

Drying Machines Protecting Mushrooms from Spoilage

Drying is one of the most important steps to keep mushrooms fresh for a long time. Fresh mushrooms contain a lot of water, which means they spoil quickly if not treated. Dryer gently remove moisture using warm air, helping mushrooms stay safe for weeks or even months. Drying is also useful for pellets made from mushroom powder or leftover substrate. Without proper drying, pellets may become soft or moldy. With drying machines, workers can control the heat and airflow to make sure everything dries evenly. This helps improve taste, appearance, and safety. As part of the production line, drying machines demonstrate how Integrated equipment enhancing mushroom processing efficiency helps protect the final product and reduce storage problems.

Cooling Machines Keeping Mushrooms and Pellets in Good Condition

After drying or granulating, mushrooms and mushroom-based products can be quite warm. If they are packed while still hot, they may get sticky, lose their shape, or take in unwanted moisture. Cooling machines help solve this by lowering the temperature in a gentle and controlled way. Cooled mushrooms keep their color and softness better, and cooled pellets stay firm and dry. Cooling prevents damage and helps keep products stable during transportation. This important finishing step highlights Integrated equipment enhancing mushroom processing efficiency, ensuring mushrooms reach customers in the best possible condition.

Simple Digital Tools Connecting the Whole Production Line

Many mushroom farms now use simple digital tools such as timers, basic sensors, and small control panels to help machines work better together. These tools can check temperature, airflow, or moisture and help workers react quickly if something needs attention. When fermentation tanks, turners, crushers, screens, granulators, dryers, and coolers are connected with digital tools, the whole production line becomes easier to manage. Workers do not need to check each machine separately and can focus on overall production instead. This kind of teamwork across machines represents Integrated equipment enhancing mushroom processing efficiency, making the workflow smoother and more predictable without complex technology.

Better Efficiency and Better Mushroom Products

Using all seven machines together—fermentation tanks, windrow turners, crushing machines, screening machines, granulators, drying machines, and cooling machines—helps mushroom farms achieve higher output and better quality with less stress. The mushrooms stay clean, dry properly, and are easier to store or transport. Waste is reduced, and each step becomes simpler for workers. This shows clearly how Integrated equipment enhancing mushroom processing efficiency supports the entire mushroom industry by lowering costs, improving quality, and creating a more organized production line.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520