In the current agricultural environment where environmental awareness is on the rise, learning how to make commercial organic fertilizer has become a popular entrepreneurial direction.

With the popularization of the green agriculture concept, more and more people are beginning to explore how to make commercial organic fertilizer in order to achieve sustainable agricultural development. This article will detail the complete production process of commercial organic fertilizers, helping beginners quickly acquire relevant knowledge.

Understand the characteristics of the raw materials

To successfully master the production of organic fertilizer, one must first understand the characteristics of the raw materials. Different raw materials require different processing methods, which is the key foundation for learning the production of commercial organic fertilizer. For example, fibrous raw materials such as straw and sawdust need to pay special attention to the fineness of the grinding and moisture control; while high-moisture raw materials such as livestock manure need to be dehydrated first before being mixed with other auxiliary materials. If multiple raw materials are mixed, special attention must be paid to the proportions of various raw materials; this is a key factor that needs to be considered in the production of commercial organic fertilizer.

Select the appropriate equipment

When choosing production equipment, the granulator is the most crucial device and also the core equipment for the production of commercial organic fertilizers.

The disc granulator is suitable for processing viscous materials and can produce round particles with uniform size.

The stirring pin granulator is specifically designed for fibrous materials such as straw and can handle relatively moist materials.

The rotary drum granulator has a stable output and uniform particle size.

The two-in-one granulator is more flexible and can adapt to various raw material formulations.

Understanding the characteristics of these machines is the key to mastering the technology of commercial organic fertilizer production.

For those who are interested in this industry, it is recommended to start with small-scale production practices of organic fertilizers.

First of all, one must understand what raw materials are available locally and what products are in demand in the market.

When purchasing equipment, it is not necessary to seek the most expensive option; instead, choose the equipment that best suits one’s own needs. These practical suggestions are crucial for entrepreneurs who want to learn how to make commercial organic fertilizer.

In the actual production process, strict control of each step is the key to ensuring the quality of the organic fertilizer.

From raw material preparation to the management of the fermentation process, and then to the granulation operation, all require meticulous attention.

A strict quality inspection system must be established to ensure the stability and reliability of the fertilizer quality. These management points are of vital importance in the production of commercial organic fertilizers and cannot be ignored.

Project Overview

This project is located in Central Java Province of Indonesia. It was jointly invested and constructed by a local agricultural enterprise and an international environmental technology company, with a total investment of approximately 5 million US dollars. The project officially started production in June 2023.

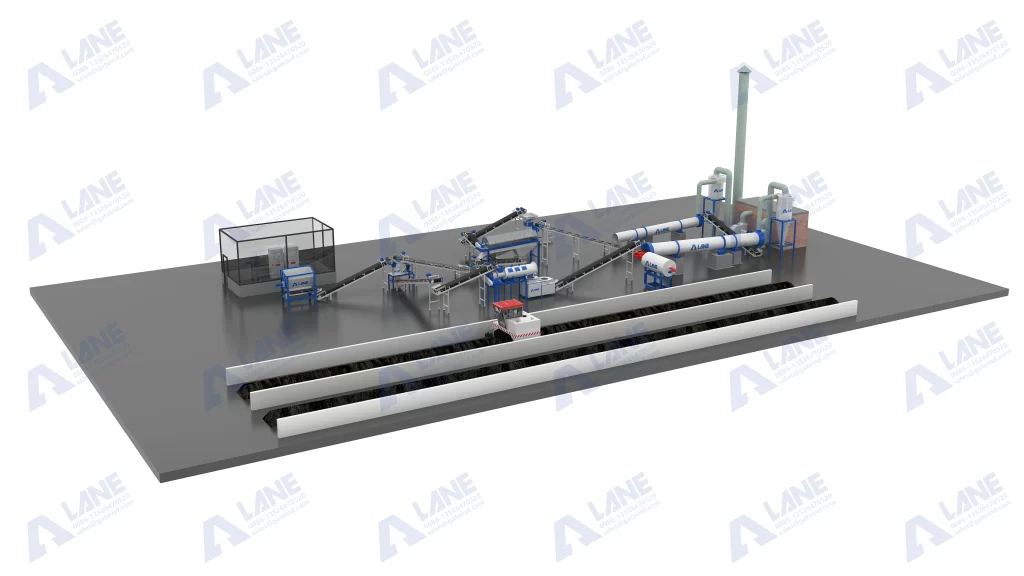

This production line is designed to process 20,000 tons of agricultural waste annually, including palm oil processing waste, livestock manure, and crop straw. It can produce 15,000 tons of high-quality organic fertilizer per year. These fertilizers are mainly supplied to Indonesian plantations and exported to neighboring Southeast Asian countries. The project adopts a modular design, integrating pre-treatment, fermentation, granulation, and packaging processes, and is equipped with advanced environmental protection systems to ensure the sustainability of the production process.

Production Process and Technology Application

The raw materials are crushed and sieved before entering the mixing system. The fermentation conditions are optimized through steam heating and microbial inoculation. The core fermentation stage employs a trough rolling process, combined with an IoT temperature control system, to achieve continuous high-temperature decomposition of organic matter at 55-65°C.

The subsequent granulation stage uses a drum granulator and adds trace elements to enhance the product value. The entire production line has two major innovations: one is the use of palm oil waste as the main carbon source, reducing raw material costs by 30%; the other is the adoption of UASB wastewater treatment technology, achieving a water resource utilization rate of over 90%.

Operational Efficiency and Social Value

The sales volume of this production line reached 8 million US dollars in its first year of operation. Its products have obtained the Indonesian SNI 7760:2018 organic certification, and key indicators such as heavy metal content all exceed industry standards. This project directly created 50 job positions and indirectly led 200 farmers to participate in the raw material supply network.

In terms of environmental benefits, this project can reduce approximately 12,000 tons of greenhouse gas emissions annually, and has applied soil improvement agents made from waste to 500 hectares of degraded farmland. In the next three years, the project plans to expand its production capacity to 50,000 tons and develop disease-resistant functional fertilizers, further consolidating its key position in the organic agricultural supply chain in Southeast Asia.

Summary

In conclusion, learning how to make commercial organic fertilizer is a process that requires patience and accumulation. Entrepreneurs should not only focus on market opportunities but also concentrate on mastering production techniques.

Through continuous learning and improvement, anyone who wants to understand how to make commercial organic fertilizer can find a path to success in this industry. As society pays increasing attention to green agriculture, mastering the production technology of commercial organic fertilizers will bring more development opportunities.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520