Why the Hydraulic Crawler Type Compost Turner Stands Out

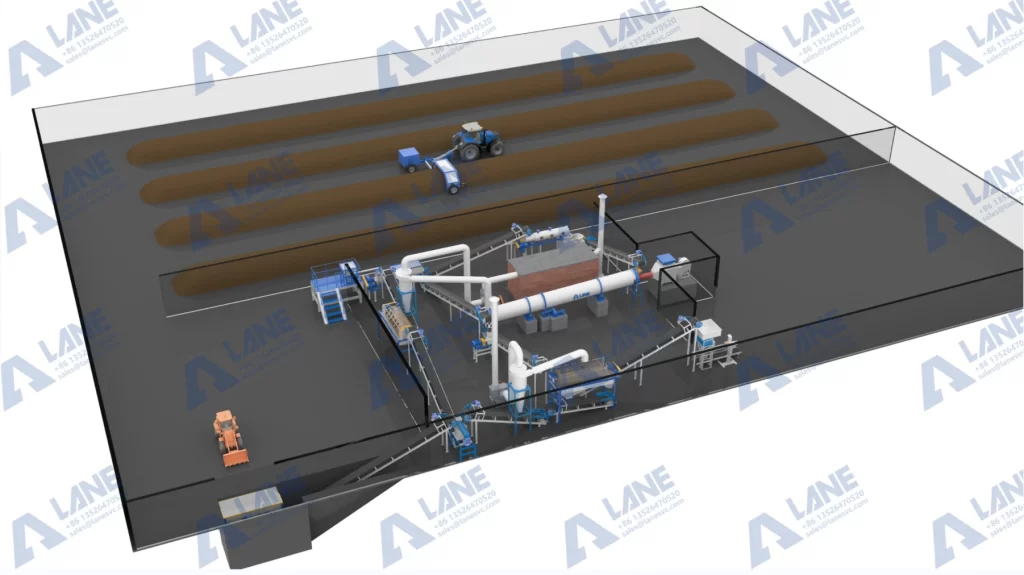

In large-scale composting operations, efficiency, mobility, and consistency are essential. The hydraulic crawler type compost turner is a powerful machine designed to transform organic waste into high-quality compost faster and with less manual labor. Thanks to its crawler tracks, robust hydraulic system, and high turning capacity, it can easily handle challenging terrains and heavy compost piles.

For farms, municipal compost facilities, and organic fertilizer manufacturers, this compost turner offers the perfect blend of strength and flexibility. At LANE, we supply hydraulic crawler type compost turners that deliver consistent performance, require minimal maintenance, and are engineered for years of reliable service.

Raw Materials Suitable for the Hydraulic Crawler Type Compost Turner

This machine is suitable for processing a variety of organic materials, including:

Poultry and livestock manure (chicken, cattle, pigs, sheep)

Agricultural waste (corn stover, rice straw, peanut shells)

Green waste from parks and gardens

Food waste from markets and processing plants

Sewage sludge from municipal treatment plants

Organic by-products from agro-industrial operations

By turning and mixing these raw materials, the hydraulic crawler type compost turner speeds up decomposition and creates a nutrient-rich, market-ready compost product.

How the Hydraulic Crawler Type Compost Turner Works

The hydraulic crawler type compost turner operates on crawler tracks for maximum traction, allowing it to navigate through long compost windrows without sinking or slipping. Its hydraulic lifting system adjusts the turning drum to the optimal depth, ensuring thorough mixing and aeration.

The powerful turning rotor lifts, flips, and breaks down the compost pile while evenly distributing oxygen. This process keeps microbial activity high, maintains proper temperature, and prevents foul odors caused by anaerobic conditions.

Key Features and Advantages of the Hydraulic Crawler Type Compost Turner

1.Hydraulic Depth Adjustment for Complete Mixing

One of the most valuable aspects of a hydraulic crawler type compost turner is its ability to adjust the turning depth on the fly. The hydraulic system lets the operator set the rotor at just the right position to dig deep into the compost windrow, breaking up compacted material and mixing it evenly. This ensures every section of the pile gets the oxygen and movement it needs for fast, uniform decomposition.

2.Crawler Tracks That Go Anywhere

Instead of relying on wheels that can bog down in soft or wet ground, this machine moves on durable crawler tracks. The added surface grip means it can keep working even when the ground is muddy, uneven, or slippery. This capability is especially important for farms and compost facilities that operate year-round and can’t afford downtime during the rainy season.

3.Handles Big Jobs with Ease

The hydraulic crawler type compost turner isn’t built for small piles—it’s made for serious volume. It can turn large windrows in a single pass, moving huge amounts of material in a fraction of the time manual or smaller machines would take. This efficiency translates into faster compost production cycles and the ability to keep up with growing organic waste streams.

4.Simplified Maintenance for Long-Term Reliability

LANE engineers these machines with fewer moving parts and a heavy-duty frame so they can stand up to constant use. The rotor and blades are made from high-strength, wear-resistant steel that lasts for many turning cycles before needing replacement. When it’s time for maintenance, access points are designed for quick servicing, helping keep downtime to a minimum.

5.Built Around the Operator

Comfort and usability are often overlooked in heavy machinery, but not here. The operator’s station is designed for good visibility and easy handling of all controls. Long shifts feel less tiring, and built-in safety features protect both the operator and the machine during demanding work.

In short, the compost turner brings together mobility, power, and ease of use in a way that few composting machines can match. It’s not just about turning piles—it’s about keeping production moving, regardless of terrain or weather. This reliability is exactly why many commercial composting operations choose LANE’s organic fertilizer production lines, knowing they will have consistent performance season after season.

Case Study – Boosting Efficiency in Southeast Asia

A large poultry farm in Southeast Asia faced challenges managing high volumes of chicken manure. Manual turning was slow and labor-intensive, and compost quality was inconsistent. After installing a LANE hydraulic crawler type compost turner, the farm reduced composting time from 50 days to just 25 days, cut labor costs by 40%, and produced uniform, high-quality compost that sold at a premium to local vegetable growers. The crawler tracks allowed them to work even during the rainy season, keeping production steady year-round.

The hydraulic crawler type compost turner is more than just a composting machine—it’s a productivity booster, a quality enhancer, and a long-term investment in sustainable agriculture. By combining high turning capacity, crawler mobility, and hydraulic precision, it transforms organic waste into valuable compost efficiently and reliably. With LANE’s advanced compost turner solutions, you can streamline your composting process, reduce operating costs, and maximize returns—whether you’re running a small farm or a large composting facility.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520