As the demand for sustainable agricultural practices grows, large capacity organic fertilizer plant design has emerged as a key component in supporting modern, eco-conscious farming systems.Gone are the days when organic fertilizer was produced on a small scale, primarily by smallholder farms or backyard composters. Today, large capacity organic fertilizer plant is not only possible, but imperative—to meet the demands of a growing population, increasingly depleted soils, and an international market that places increasing emphasis on organic certification and environmental stewardship.

Designing a high-volume organic fertilizer facility is more than simply scaling up a basic composting site. It requires the careful integration of multiple disciplines: industrial engineering, microbiology, environmental science, and agricultural market forecasting. The end result should be a system that efficiently, cleanly, and effectively converts organic waste into a nutrient-rich, market-ready product.

The Significance of Large Capacity Organic Fertilizer Plant Design

At its core, large capacity organic fertilizer plant design is about achieving balance: between efficiency and sustainability, between technology and biology, between capital investment and long-term returns. A well-designed facility should be capable of processing tens of thousands of tons of organic material annually, using scalable systems that accommodate multiple types of feedstock such as livestock manure, crop residues, food waste, and industrial byproducts.

The reason of large capacity organic fertilizer plant design is so important is because of the complexity and scale of their operations. These are not stand-alone machines, but complete ecosystems—from raw material intake to final product packaging, and every biological, chemical, and mechanical transformation process in between. The stakes are high: bad design can lead to production bottlenecks, bad odors, non-compliance, and poor product quality. In contrast, smart design can maximize productivity while minimizing environmental and economic costs.

A Systems Approach to Large Capacity Organic Fertilizer Plant

The first step in designing a large capacity organic fertilizer plant is to adopt systems thinking. This means viewing the plant as an interconnected stream of inputs, processes, and outputs. From the building layout to the type of composting technology selected, every decision affects the overall performance of the system. For instance,the physical layout must allow materials to move seamlessly between processing stages, reducing the need for excessive manual handling or transportation. Strategically zoning composting areas, mixing and granulation lines, drying units, and storage facilities ensures that each stage can support the next in a streamlined manner.This is particularly important when operating at high throughput levels, where even minor delays or inefficiencies can snowball into significant production losses.

Automation is also a central feature of modern large capacity organic fertilizer plant design. Sensors, programmable logic controllers (PLCs), and smart monitoring systems now allow for precise control of key variables such as temperature, moisture content, and aeration during composting. These tools not only improve product quality and uniformity but also reduce labor costs and human error. In highly advanced facilities, even packaging and palletizing operations are handled by robots, supervised through centralized control rooms.

Core Equipment in Large Capacity Organic Fertilizer Plant Design

A fully functional large capacity organic fertilizer plant must be equipped with a range of industrial machinery, each optimized to achieve high output, consistent performance, and minimal downtime. The specific machinery required may vary depending on the feedstock, desired product form (powder or granules), and scale of production, but most high-capacity facilities typically include the following equipment.

1.Organic Raw Material Crusher

Before composting or fermentation can begin, bulky organic waste such as crop straw, animal manure, or food waste must be shredded or crushed to improve surface area and microbial activity. High-moisture materials require specially designed wet crushers, while dry materials can be processed using hammer mills or chain crushers.

Function: Break down large organic material into fine particles

Typical models: Semi-wet crusher, vertical shaft crusher, cage crusher

Uniform mixing of raw materials ensures balanced nutrient content and optimal fermentation. In large-scale plants, horizontal or vertical mixers with automatic batching and feeding systems are used.

Function: Homogenize feedstock composition before fermentation

Types: Horizontal mixer, double shaft mixer

3.Composting or Fermentation Equipment

The heart of the large capacity organic fertilizer plant is microbial fermentation. This stage decomposes organic matter into stable humus-like material. For high-capacity plants, efficient and space-saving composting methods are essential.

Options include:

Groove Type Compost Turner: Operates in fermentation trenches; efficient and scalable.

Wheel Type Compost Turner: Ideal for very large piles; high turning capacity.

Crawler Type Compost Turner:Small footprint; easy operation; high working capacity.

In-vessel Fermenter: Closed system with full control over temperature and moisture; minimal odor.

Function: Biodegradation of organic material using aerobic fermentation

4.Granulation Machine (for granular fertilizer)

If the end product is granular (preferred for commercial distribution), a granulator is used to shape the material into uniform pellets. Granulation improves usability, transport, and shelf life.

Common granulation machines include:

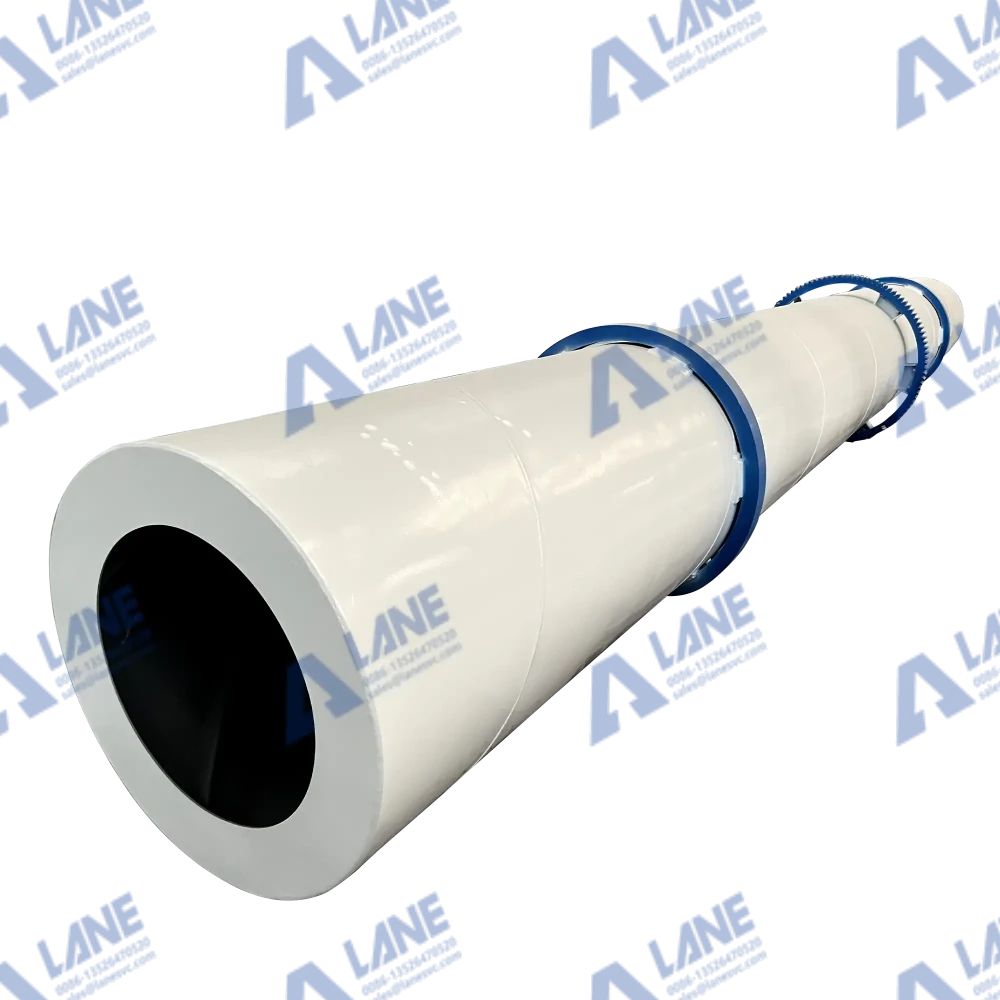

Rotary Drum Granulator – High output, suitable for large-scale continuous production.

Disc Granulator – Flexible control over granule size.

Double Roller Granulator – Dry granulation without need for drying process (for powdery formulations).

Function: Turn fermented compost into uniform fertilizer granules

Granules must be dried to reduce moisture content to less than 15%, ensuring stability and preventing mold or caking. After drying, cooling helps maintain granule integrity and allows safe packaging.

Function: Reduce moisture and stabilize product

Components:

Rotary Dryer

Rotary Cooler

Induced Draft Fan

Heat source (biomass, natural gas, or waste heat)

6.Dust and Odor Control Systems

For environmental compliance and workplace safety, a dust collection system and odor control units are essential.

Components include:

Cyclone dust collectors

Bag filter units

Biofilters or activated carbon towers

Ventilation fans

It can grade the freshly made fertilizer pellets, screen out the ones that meet the specifications (usually 2 – 6mm), and send the oversized pellets back to the crushing equipment for reprocessing, while recovering the undersized powder for reuse, ensuring uniform pellet size and enhancing product quality.

Types: Rotary Screen Machine;Vibration Screen Machine

Some commercial fertilizers are coated with organic polymers or trace elements to enhance slow-release effects or improve appearance.

Function: Add protective or functional coating to fertilizer granules

Final products are automatically weighed, bagged, sealed, and stacked for storage or shipment.This is also very beneficial for commercial sales.

Function: Automate final packing process for powder or granular fertilizer

Features: Auto-weighing, sealing, printing, and palletizing

Sustainability and Waste Management

Sustainability is more than a buzzword—it’s a design imperative in large capacity organic fertilizer plant construction.Beyond simply recycling waste into fertilizer, the best designs seek to minimize their own environmental footprint. This involves addressing issues such as odor emissions, leachate (liquid runoff from waste decomposition), dust generation, and energy consumption.

Effective odor management begins with a closed composting system and continues with the use of biofilters, activated carbon scrubbers, or other air purification systems. Leachate must be collected through a well-designed drainage system and treated on-site to prevent groundwater contamination. Dust suppression systems, such as sprayers or enclosed conveyors, help keep air quality within legal and safety limits.

Energy efficiency is another key pillar. Modern large capacity organic fertilizer plants often integrate renewable energy systems, such as solar panels or biogas recovery units, to offset their electricity needs. Some fertilizer plants even use waste heat from the composting or drying process through heat exchangers or thermal storage systems. These methods not only reduce operating costs, but can also improve a plant’s environmental compliance, especially in areas with strict emission standards.

Economic Planning and Return on Investment in Large Capacity Organic Fertilizer Plant

While sustainability and technical precision are critical, any large capacity organic fertilizer plant must also balance financials. The costs of building a large capacity organic fertilizer plant vary widely, depending on location, technology choice, and scale. These costs include land acquisition, equipment procurement, building construction, utility setup, and environmental compliance systems.

The return on investment (ROI) depends on a variety of factors: the selling price of the fertilizer, access to reliable raw materials, operating costs, and the efficiency of the production process. In many regions, government subsidies, carbon credits, and tax incentives for green manufacturing can significantly improve financial performance. In addition, by-products such as biogas or compost soil conditioners can provide additional revenue streams.

A well-run large capacity organic fertilizer plant can break even within 3 to 5 years, and profit margins can be very attractive thereafter – especially if the brand is associated with certified organic inputs or high nutritional value formulas.

From Blueprint to Reality: The Road to Operational Success with LANE

Transitioning from design to operation is a complex process that requires not only careful planning, but also extensive experience and execution across multiple disciplines. At LANE, we understand that delivering a truly operational, large capacity organic fertilizer plant is much more than simply providing equipment. Our integrated project management approach ensures that every stage, from initial design to post-installation support, is aligned with long-term success.

Once the blueprint is finalized, LANE’s engineering and technical team will provide comprehensive on-site construction supervision to ensure that structural components, mechanical equipment, and auxiliary systems are accurately installed and seamlessly integrated. From composting equipment to automated packaging lines, each component is calibrated for performance, safety, and efficiency.

During the commissioning phase, our experts will oversee comprehensive trial runs, system integration, and real-time calibration of the control system. This includes PLC programming, sensor verification, and functional testing of each production module. At the same time, we also provide on-site training for your employees, covering not only equipment operation, but also maintenance, safety procedures, and production optimization.

What truly distinguishes LANE in the fertilizer machinery industry is our all-inclusive after-sales service platform. We know that smooth operation depends on proactive support, which is why we provide:

(1) Remote monitoring and diagnostics, offering real-time operational insights and fast technical support

(2) Routine inspection and maintenance scheduling, helping you avoid unexpected downtime

(3) A full inventory of critical spare parts, ensuring immediate availability when replacements are needed

(4) Continuous software updates and system enhancements, keeping your facility aligned with the latest automation trends

(5) Custom service contracts, with flexible plans for monthly, quarterly, or annual plant servicing

Whether your plant is located in Asia, Africa, Europe, or the Americas, LANE delivers more than machinery—we deliver a fully functional, future-proof organic fertilizer production system backed by global experience and local commitment.With LANE, your vision of a large capacity organic fertilizer plant becomes a reality—engineered with precision, supported by expertise, and powered by reliability.

Designing the Future of Large Capacity Organic Fertilizer with LANE

The shift toward sustainable agriculture is not a trend—it’s a necessity. In this context, large capacity organic fertilizer plant design plays a pivotal role in transforming organic waste into high-value agricultural inputs, supporting food security, environmental restoration, and circular economies worldwide.

A well-executed plant design is more than the sum of its parts. It requires a systems approach that balances biological processes with industrial engineering, integrates automation for efficiency, and incorporates environmental controls to meet regulatory and ethical standards. From raw material intake and composting to granulation, drying, and automated packaging, each step must be optimized for throughput, quality, and long-term viability.

What truly determines success, however, is the ability to move from blueprint to operational excellence—and that’s where LANE makes the difference.

As a leading provider of large capacity organic fertilizer plant, LANE offers end-to-end services that include customized plant design, professional installation, intelligent automation, and world-class after-sales support. Whether you’re building a 10,000-ton facility or a 100,000-ton industrial complex, LANE delivers not only the equipment but the expertise to ensure your plant operates efficiently, sustainably, and profitably.

Our commitment doesn’t end when construction is complete. With remote monitoring, spare parts support, routine maintenance, and on-site training, LANE becomes a long-term partner in your success—providing peace of mind and consistent performance throughout your plant’s lifecycle.

In a world where both environmental responsibility and agricultural productivity are paramount, investing in large-scale organic fertilizer production is a forward-looking decision. And with the right partner by your side, that decision becomes a smart, strategic, and sustainable success.

Choose LANE. Build smart. Grow green. Feed the future.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520