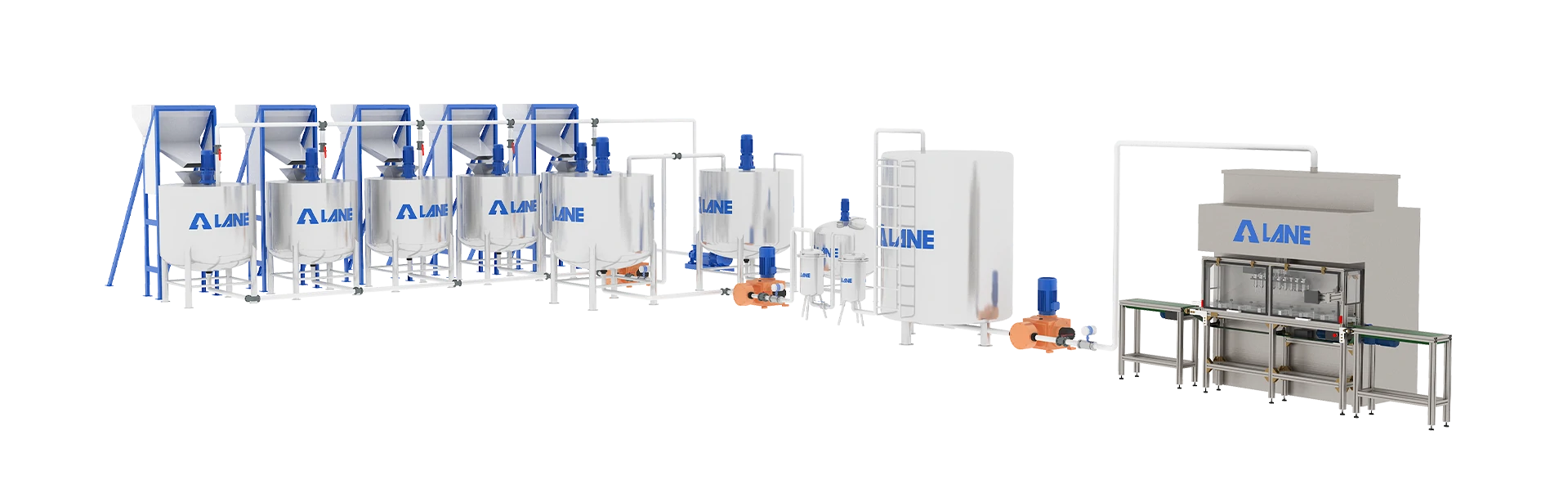

Custom-Built & Full-Service ✅ Complete Systems - Crushers to filling machinesM ✅ Tailored Solutions - Scale (1-200TPD) & formula customization ✅ End-to-End Service - Design, install, train, certify

Made of SUS 304 or SUS 316L stainless steel, it can resist corrosion from chemical substances such as acid, alkali, and salt, and is suitable for various chemical, pharmaceutical, and food industries. Advanced mixing technology can quickly and evenly mix materials of different ingredients to improve product quality and production efficiency.

The mixing tank body and mixing blades of the liquid fertilizer fermentation tank have smooth surfaces, and with the CIP (cleaning in place) system, they are easy to clean and disinfect quickly to reduce cross contamination. Moreover, the design is reasonable, which can effectively reduce energy consumption, and has heating, cooling and other functions to meet different process requirements.

The stainless steel mixing tank plays an important role in the production of liquid fertilizers with its excellent materials, reasonable structural design and efficient working performance, and is a key equipment to ensure product quality and production efficiency.

If you are looking for a dehydrator for an organic fertilizer production plant, you can definitely consider our company. We have rich production experience in producing fertilizer dehydration equipment.

Among them, our inclined solid-liquid separator is a small machine for treating organic waste with a high water content (>85%). The machine occupies an area of only 3-6m. Obviously, it is suitable for material pretreatment in small organic liquid fertilizer plants.

Generally speaking, the smallest scale can process 20-25m:/h of cow dung, pig dung or sludge; 10-15m'/h of chicken manure or Chinese medicine residue; 15-20m'/h of wine lees, etc.

In addition, our factory can also customize the specifications of the filter according to the customer's material requirements. Secondly, the whole machine is made of 304 stainless steel to meet the needs of liquid and sticky manure treatment.

The double filter consists of two single bag filters and a three-way ball valve. It has a simple structure and intuitive operation. It can also be used for pre-treatment of wastewater filtration. Due to the presence of two independent alternating filter units, the wave-state organic manufacturing process can be operated continuously for 24 hours.

You only need to install this double filter in each step of liquid organic fertilizer production to improve the quality of the finished liquid fertilizer. A two-stage filtration system can be set up, the first filter unit removes medium-sized particles and impurities, and the second filter unit removes finer substances.

In addition, we can customize the filter element material according to customer requirements-carbon steel, 304, 316 stainless steel, and the filter surface has mirror or matte for you to choose.

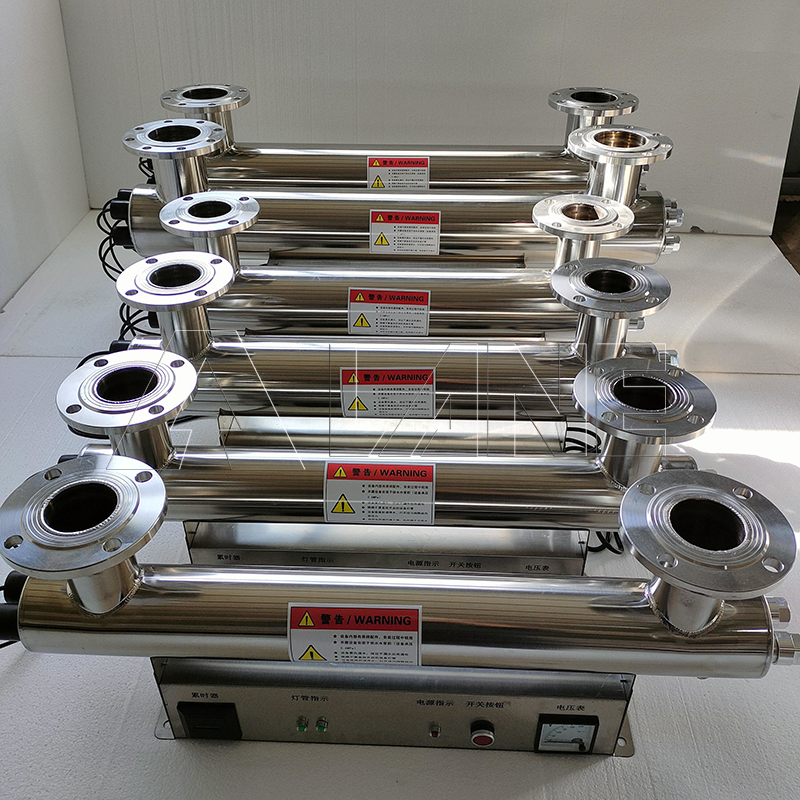

The filtered liquid organic fertilizer needs further treatment, such as UV disinfection or microfiltration, so we basically equip the duplex filter with a UV sterilizer.

he inside and outside of the main body are made of 304 or 316 stainless steel, and are polished to improve the UV irradiation effect. It is suitable for various water treatment projects, including sewage treatment projects, drinking water disinfection, etc.

Its purpose is to kill bacteria, viruses, yeast, bacteria, algae and degrade chlorides in the water. UV sterilization has the strongest sterilization ability at a wavelength of 253.7nm, so it can be adjusted through the control cabinet.

In general, we guarantee product quality and use PHILIPS brand UV lamps with an effective service life of more than 12,000 hours. In addition, we provide a 10-year warranty on the stainless steel shell and a 1-year warranty on other accessories.