How to Build a Low-Cost Organic Fertilizer Production Line with LANE Heavy Industry Machinery

Introduction: The Value of Going Organic & Low-Cost

The global promotion of green agriculture is creating strong demand for organic products. This demand is increasing for farms that rely only on organic inputs. For farmers, cooperatives, and agri-entrepreneurs, this creates a real financial opportunity. However, many investors mistakenly believe that high capital is required to enter the organic fertilizer industry. This guide will break that myth. Building a Low-Cost Organic Fertilizer Production Line is a high-return investment.

LANE Heavy Industry, a professional manufacturer of agricultural machinery, provides cost-effective and reliable equipment solutions that help investors with limited budgets successfully build a Low-Cost Organic Fertilizer Production Line. Our low-cost organic fertilizer production line turns agricultural, municipal, and livestock waste into a consistent and sustainable revenue stream.

Core Philosophy: What Makes a Production Line “Low-Cost”?

Low-cost doesn’t mean low quality. It means optimization.

- Right-Scaling: You invest in capacity that matches your available raw materials and market demand.

- Minimizing Frills: We prioritize core functionality over automation in the initial phase.

- Durability Over Novelty: Choosing machinery that has low maintenance costs and easy repairability.

- Integrated Site Planning: Using existing space and infrastructure to reduce construction costs.

A well-planned low-cost organic fertilizer production line minimizes capital outlay while maximizing output quality and long-term reliability.

Phase 1: Pre-Production & Material Sourcing

Before purchasing any machine, you must first lay the groundwork.

- Raw Material Audit: Identify local low-cost or free raw materials like animal manure (poultry, cattle), crop residues, food processing waste, and municipal green waste. The supply of the raw material must be consistent.

- Site Selection: Choose a location with good drainage, ventilation, and space for raw material storage, composting, and machinery operation.

- Permitting & Compliance: Check local regulations for waste processing and fertilizer production. Get compliance to prevent any mishaps from happening later.

- Market Research: Define your product and identify buyers. Create pre-sales agreements.

Phase 2: Essential Machinery for Your Line

This is the heart of your low-cost organic fertilizer production line. The production line must be interactive and every machine should be synchronized. LANE Heavy Industry is renowned for building durable, industrial-grade equipment perfect for this goal.

Fermentation & Composting (The Foundation)

- Process:This is where microorganisms break down raw materials. A dedicated compost turner speeds up this process.

- LANE Machinery Recommendation: LANE Crawler Compost Turner.This machine is a workhorse for a low-cost production line. It efficiently aerates windrows, controls temperature and moisture, and reduces odor. Its durability and easy maintenance with high uptime make it the perfect choice for this stage.

Crushing & Grinding (Creating Uniformity)

- Process:After fermentation and curing, the compost contains clumps and fibers. This must be broken down into fine powder for granulation or direct sale.

- LANE Machinery Recommendation: LANE New Vertical Crusher/Hammer Mill.These crushers are designed for high-torque crushing of organic materials. They ensure uniform fine particles, which is crucial for granulation.

Granulation (Adding Market Value)

- Process:Converting fine powder into uniform, easy-to-handle granules commands a higher market price and reduces dust.

- LANE Machinery Recommendation: LANE Disk or Stirring Pin Organic Fertilizer Granulators.The disc granulator is a classic, low-cost choice. It uses a rotating disc and liquid binder to form granules. For higher strength and uniformity, LANE’s stirring pin granulator uses mechanical pins to create a cyclone and friction to create excellent quality granules.

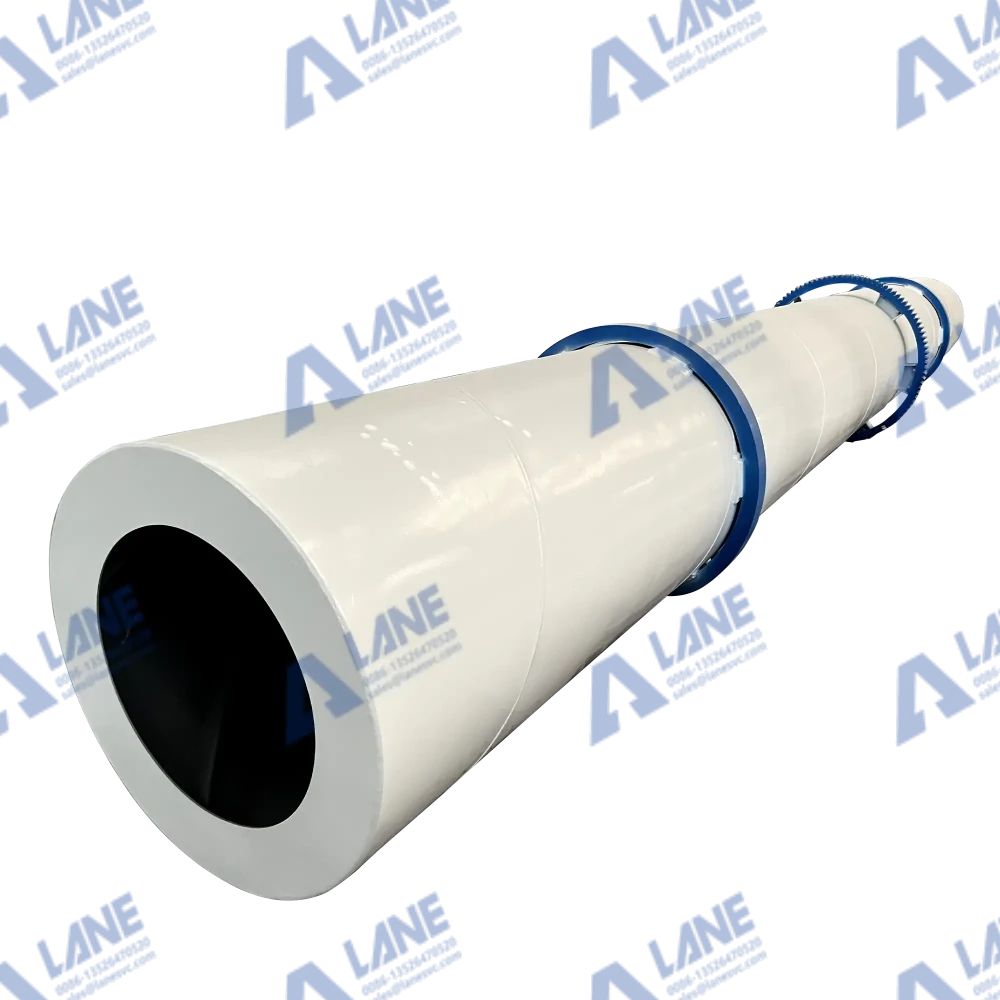

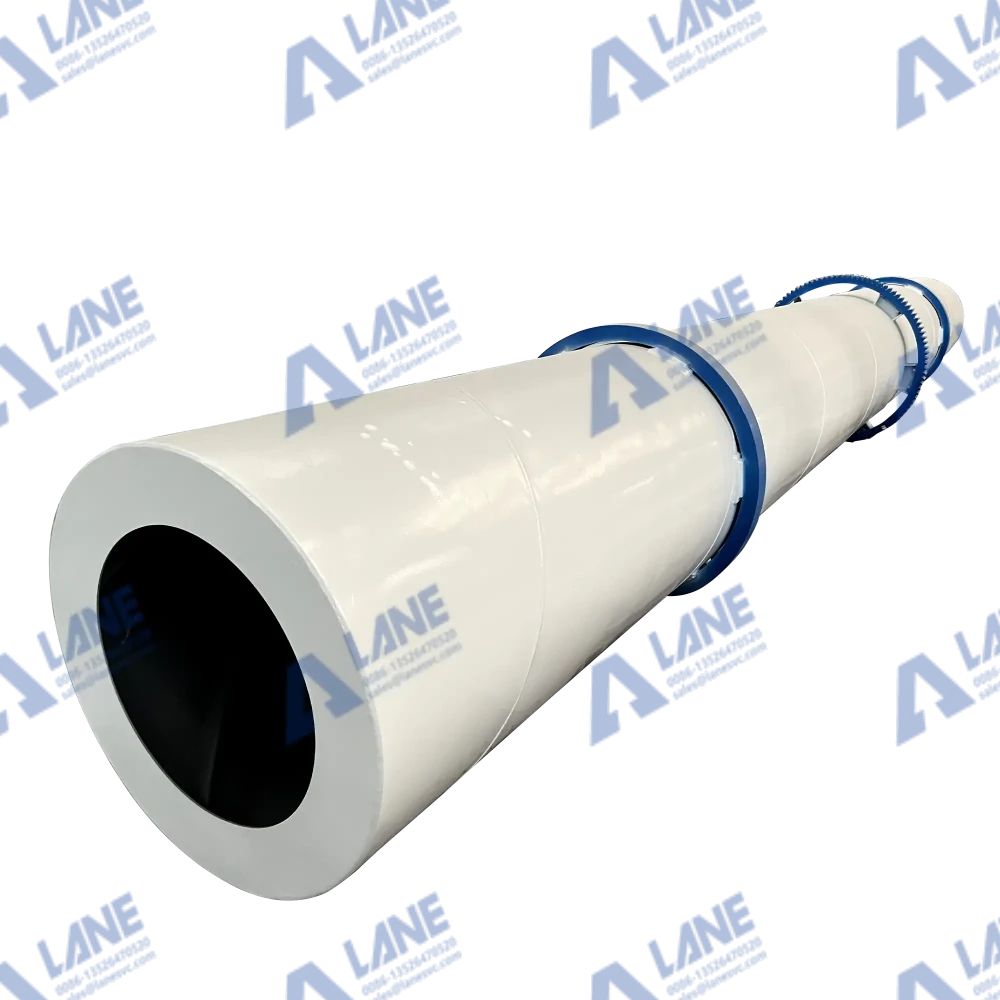

Drying & Cooling (Stabilizing the Product)

- Process:Drying reduces moisture to prevent caking and spoilage during storage. Cooling protects nutrient integrity.

- LANE Machinery Recommendation: LANE Rotary Drum Dryer & Cooler.These drums use hot air and ambient air to dry and cool the granules. Their efficient, rotating drum design ensures even treatment of all granules.

Screening & Packaging (Final Polish)

- Process: Screening separates on-size granules from dust and oversize granules. They are sent back to the crusher, and on-size granules are sent to an automatic packing machine, ensuring smooth material flow in a Low-Cost Organic Fertilizer Production Line.

- LANE Machinery Recommendation: LANE Rotary Screening Machine.It’s a simple, motor-driven rotary sieve that reliably sizes granules. For packaging, a basic LANE Automatic Weighing and Sewing Packager automates the final step and improves efficiency.

Phase 3: Assembly, Workflow, and Cost-Saving Operation Tips

Typical Workflow:

- Pre-processing: Mix raw materials to achieve optimal Carbon-to-Nitrogen ratio.

- Fermentation: Use the LANE Compost Turner regularly for 15-30 days.

- Crushing: Feed composted material into the LANE Crusher.

- Granulation: Feed powder into the LANE Granulator.

- Drying & Cooling: Transfer wet granules through the LANE Dryer and Cooler.

- Screening & Packaging: Final separation via the LANE Screening Machine, then bagging.

Cost-Saving Operational Tips:

- Train a local technician on basic maintenance for your LANE machinery to avoid expensive service calls.

- Start with a single 8-hour shift to master the process before expanding.

Calculating ROI: When Will Your Line Pay for Itself?

ROI depends on scale and market. A simplified example for a small low-cost organic fertilizer production line:

- Estimated Line Cost (with LANE machinery):$50,000 – $80,000

- Daily Output:5-10 tons of granular fertilizer

- Sale Price:$150 – $250 per ton

- Operating Cost:$50 – $80 per ton

- Daily Gross Profit:(5 tons * $200/ton) – (5 tons * $65/ton) = $675

- ROI Timeline: Initial investment / Daily Gross Profit ≈ 74-118 working days (excluding non-production days and market build-up). This illustrates the powerful potential of a well-executed plan.

Conclusion: Empowering Sustainable Agriculture

Building a Low-Cost Organic Fertilizer Production Line is a profitable venture. It transforms waste management costs into profits and helps improve soil health. With the cost-effective equipment and professional technical support of LANE Heavy Industry, investors can effectively control the initial investment and operation costs. Partnering with an experienced manufacturer like LANE Heavy Industry provides the reliable mechanical foundation needed to start small, grow steadily, and build a truly sustainable Low-Cost Organic Fertilizer Production Line business from the ground up.

FAQ

Q1: What is the minimum space required for this production line?

A1: A well-organized setup typically requires at least 1,000 to 2,000 square meters for composting areas, machinery placement, and raw/finished product storage.

Q2: Can LANE Heavy Industry provide a complete layout and installation guide?

A2: Yes. Reputable manufacturers like LANE typically provide foundational layout drawings and detailed operational manuals for their equipment. For a first-time setup, it is advisable to work with a local engineer or the company’s technical team to finalize the site-specific plan.

Q3: Is powdered fertilizer cheaper to produce than granular?

A3: Yes. Powder production skips the granulation, drying, and cooling stages, requiring less machinery and energy. However, granular fertilizer is often preferred by the market for its ease of use, storage, and higher selling price, which usually justifies the extra steps.

Q4: What is the most common bottleneck in a low-cost line?

A4: Inconsistent fermentation (Phase 1) is the most common bottleneck. Using an efficient compost turner like the LANE model and carefully controlling material ratios and moisture from the start ensures smooth, efficient processing in all subsequent stages.

Q5: How do I ensure my organic fertilizer meets local quality standards?

A5: Regularly send samples to an agricultural lab for nutrient (NPK) and pathogen analysis. Adjust your raw material recipe based on the results. Proper composting with the LANE turner is critical for achieving safe, stable, and standardized product quality.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520