People first started making coated fertilizer over 50 years ago. Fertilizer technology has advanced significantly in the decades since this pioneering achievement.

Coated fertilizers are similar to long-acting prescription or over-the-counter medications that release slowly over time. In pharmaceuticals, the outside of the tablet is coated with one or more layers of material that controls the release of the active ingredients inside the tablet. After the sustained-release tablet enters the body, the outer layer will slowly dissolve and the active ingredients in the tablet will gradually be released over a certain period of time.

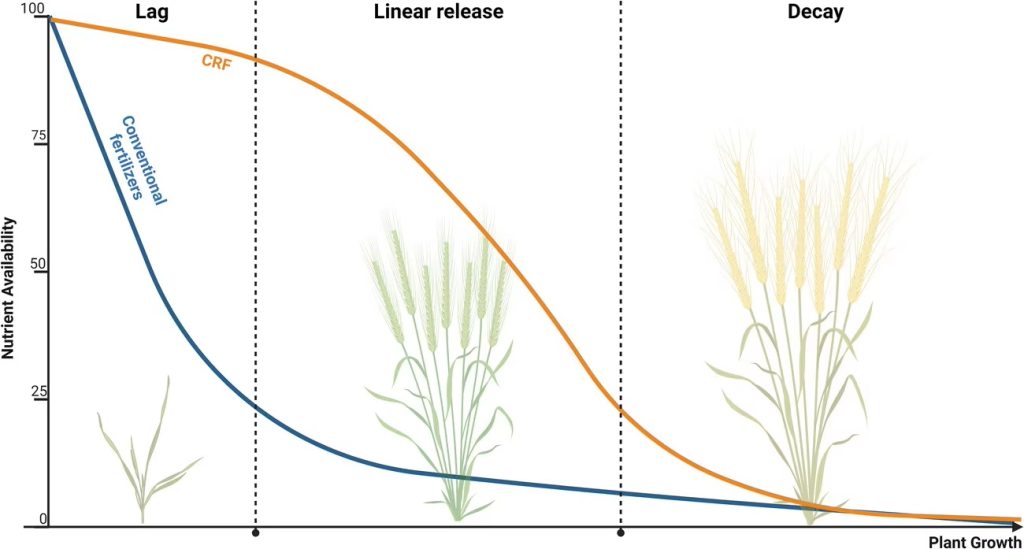

Coated fertilizers are designed in much the same way. A special coating on the fertilizer granules regulates the rate of nutrient release. Coating material and thickness, moisture content and soil temperature all play a role. Controlling nutrient release has multiple benefits, including improved plant health and yields, reduced environmental impact, lower labor costs and increased profits.

Using the manufactured coated fertilizer, a single application can provide nutrients for the entire growth cycle of the plant.

The coating around the pellets minimizes nutrient runoff and loss, making cultivation more sustainable. Also, because plants grow evenly and slowly using coated fertilizers, the crops are less susceptible to damage and disease.

LANE can provide you with professional technical support. We have a fully automatic stainless steel coating machine and supporting coating agent to realize the process of making coated fertilizer.

By the clockwise rotation of the pot, the powder rolls and rubs in the pot; gradually aggregates into spherical particles; and continues to roll and grow.

The granular materials roll in the pot, and the coating liquid fully coats the particles. Through the liquid spray device, the coating liquid and the particles are fully integrated, and the color of the particles can be changed.

It is also equipped with a heating device to remove moisture from the surface and shorten the fertilizer coating time.

1. Spray device: accurately spray liquid on the surface of particles, and accurately measure the spray volume.

2. High efficiency: high balling rate and high production efficiency.

3. Smooth granules: Compared with disc granulation, the finished granules processed by the coating machine have a smoother appearance.

4. Multi-function: The powder can be processed into spherical particles and can also be used for coating the particles.

5. Automation: Use automated control systems to achieve automated production.

The coating agent is a light-colored transparent liquid with excellent anti-caking properties. It can also improve the appearance of the product. It has good water solubility and biodegradability. It is easy to use without adding any solvent. It is chemically stable and non-toxic. , no odor, non-corrosive, non-flammable, and no pollution to the environment.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

https://organicfertilizerline.com/

Email: sales2@lanesvc.com

Contact number: +86 15515885328

Whatsapp: +86 15515885328