With the growing global demand for high-efficiency fertilizers, the Mannheim potassium sulfate production line has become one of the key technologies for fertilizer manufacturers. Potassium sulfate, as a high-quality potash fertilizer, can effectively increase crop yields and improve soil structure, so it is widely used in agricultural production. This article combines the product information of several chemical equipment companies to explore the latest developments and characteristics of the Mannheim potassium sulfate production line.

At present, the production methods of potassium sulfate are mainly divided into two categories. One is resource-based potassium sulfate made from natural potassium-containing brine, and the other is processed potassium sulfate using potassium oxide as raw material. Its production process can be divided into thermal and wet methods. The typical thermal process is the Mannheim process, and the wet process mostly uses double decomposition. Others include ammonium sulfate method, ion exchange method, and salt bittern method. At present, the Mannheim potassium sulfate process is the main process for processed potassium sulfate.

The Mannheim potassium sulfate production line uses potassium chloride and sulfuric acid as the main raw materials, and generates potassium sulfate and hydrogen chloride gas through high-temperature reaction. The characteristics of this process are mature technology, easy availability of raw materials, and high production efficiency. At present, many chemical companies have further improved the automation level and environmental performance of production by improving equipment and processes.

Ore extraction: The technical characteristics of the potassium sulfate industry show that potassium sulfate is mainly derived from natural ores, such as pyrite and brine sediments. Ore extraction technology includes ore mining, crushing, flotation, dehydration and other steps. Among them, flotation is a commonly used ore dressing method, which separates potassium sulfate ore from other impurities through physical and chemical reactions.

Modification technology: Potassium sulfate can be modified by chemical and physical means to meet specific needs. For example, the crystal form, particle size, solubility and other characteristics of potassium sulfate can be changed by solution crystallization, microbial transformation, solid reaction and other methods. Modification technology can improve the utilization rate, slow release effect, chemical stability and so on of potassium sulfate.

The modern Mannheim potassium sulfate production line is equipped with advanced control systems such as PLC and DCS control, which realizes fully automated management from raw material transportation to finished product packaging. These systems not only improve production efficiency, but also effectively reduce operational errors and safety risks. LANE’s equipment is designed with durability as the core, and provides a warranty of several years to ensure long-term stable operation.

The by-product hydrogen chloride gas generated during the production process will have a serious impact on the environment if it is directly discharged. For this reason, many production lines are equipped with efficient waste gas absorption and treatment systems to convert hydrogen chloride into industrial hydrochloric acid to further reduce emission pollution. The production lines provided by LANE focus on environmental protection and energy saving to ensure compliance with strict emission standards.

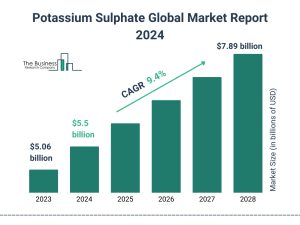

The global potash fertilizer market demand continues to grow, especially in agriculturally developed areas. The demand for high-quality fertilizers has prompted more and more companies to introduce Mannheim process production lines, which can not only meet domestic market demand, but also have strong export capabilities. In the future, with increasingly stringent environmental regulations, low-energy consumption and low-emission Mannheim potassium sulfate production lines will be further promoted.

The Mannheim potassium sulfate production line has become an important part of global fertilizer production with its mature technology, environmental advantages and efficient production capacity. Through continuous innovation, major equipment manufacturers have provided stable and reliable production line solutions for the fertilizer industry to meet the needs of global agricultural production.

Henan Lane Heavy Industry Machinery Technology Co., Ltd., Zhengzhou, has been providing customized process and production line solutions for equipment manufacturing for the fertilizer industry for more than 20 years, including organic fertilizer production lines with an annual output of 1,000-200,000 tons, compound fertilizer production lines with an annual output of 1,000-300,000 tons, water-soluble fertilizer production lines with an annual output of 1,000-2—– tons, and liquid fertilizer production lines. We can not only provide you with production line solutions, but also solve other production problems for you.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales2@lanesvc.com

Tel: +86 15515885328

Whatsapp: +86 15515885328